Cofferdam device for controlling waste working face in landfill

A technology for working surface and landfill site, which is applied in the field of cofferdam device to control the garbage working surface of landfill site, which can solve the problems of large exposed area of slope, large area of garbage paving, and aggravation, so as to reduce the exposed area of operation, Optimized separation of rain and sewage, and the effect of reducing foul odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

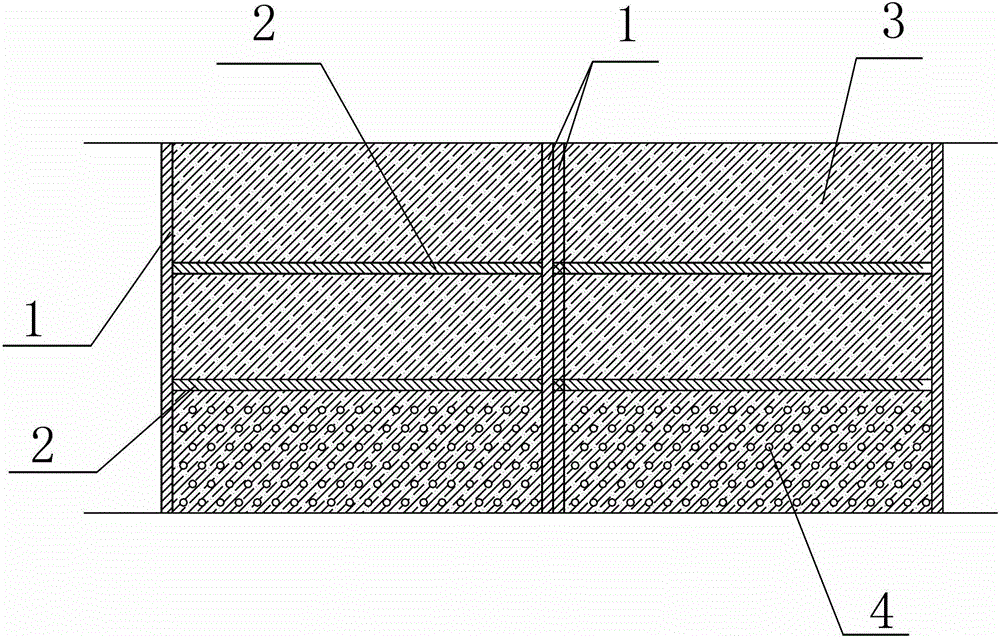

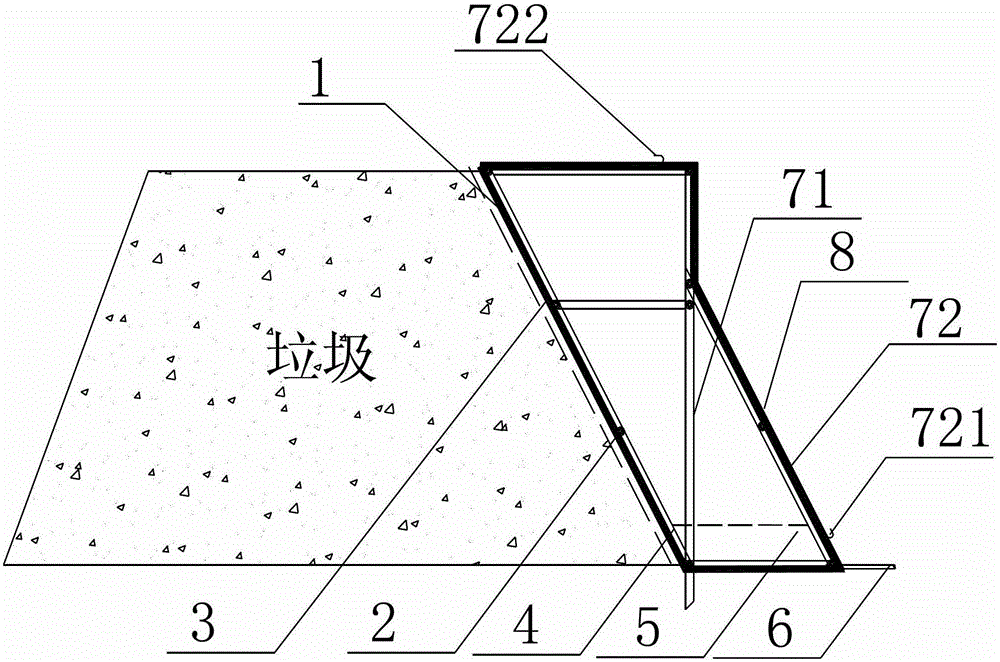

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 for in figure 1 The left side view after adding the support rod vertical to the ground and the oblique support rod inserted into the ground. Such as Figure 1-2 Shown: the vertical support column 1 and the horizontal support column 2 of the present invention, the vertical support column 1 and the horizontal support column 2 are welded into several "mesh"-shaped frames, the surface of the frame is welded with a baffle plate 3, and the baffle plate 3 The part close to the ground is the perforated section 4 with leaking holes on the surface, and a sewage tank 5 is installed at the bottom of the perforated section 4, and the sewage tank 5 is a groove made of a plastic plate, with holes connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com