Segmental hoisting process of ultra-large-span steel truss

A technology of segmented hoisting and steel truss, applied in construction, building structure, processing of building materials, etc., can solve the problems of long time, large labor force, difficult control of welding quality of cross-section geometry, etc. State-of-the-art, safety and quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with examples.

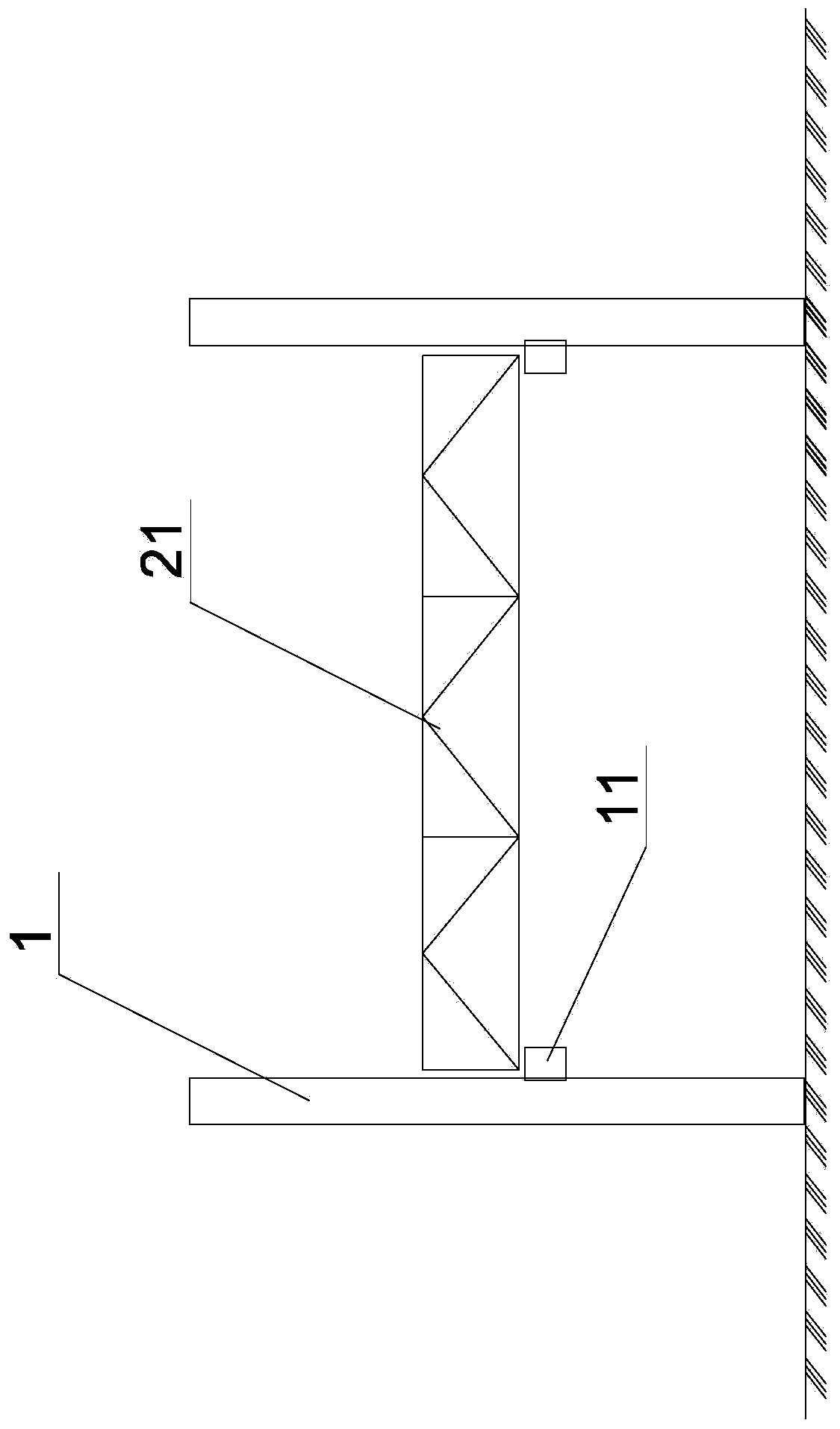

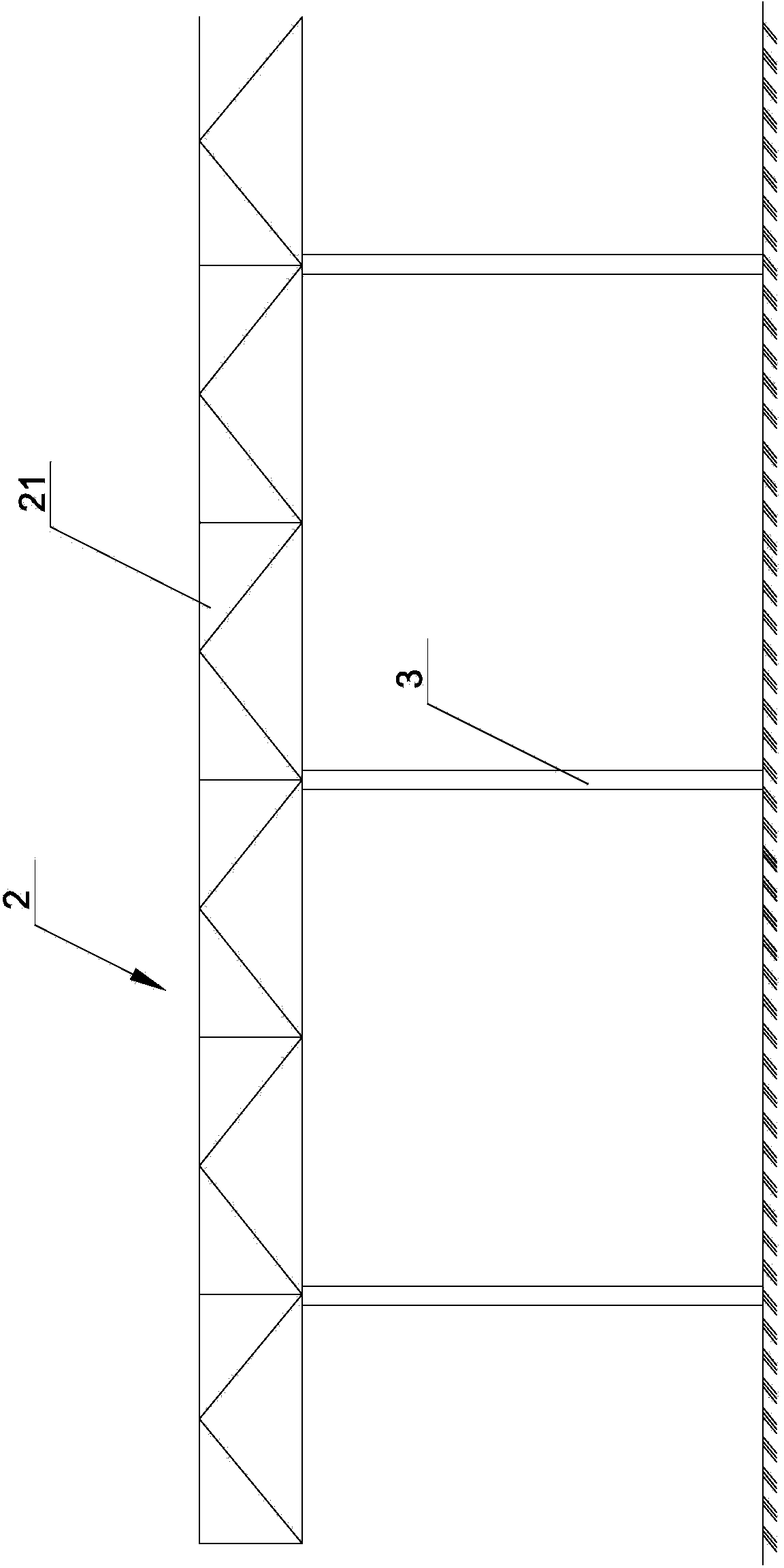

[0019] figure 1 It is a structural schematic diagram of segmental hoisting of a super-large-span steel truss according to an exemplary embodiment of the present invention.

[0020] Now, the segmental hoisting process of a super-large-span steel truss according to an exemplary embodiment of the present invention will be described in detail, which mainly includes the following steps:

[0021] Step 1: set up the steel truss vertical lifting device 1;

[0022] Step 2: Divide the overall steel truss into several sections, and assemble each section of steel truss 21 on the ground;

[0023] Step 3: If figure 1 As shown, the vertical lifting device 1 is provided with a fixed support 11 that can be lifted vertically, and the segmented steel trusses 21 are respectively placed on the fixed supports 11 of the corresponding vertical lifting device 1;

[0024] Step 4: Lift the steel trusses 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com