Method for reinforcing steel tube truss tubular joint through ring opening sleeves

A technology of intersecting joints and reinforced steel pipes, which is applied in building maintenance, construction, building construction, etc., can solve problems such as weak radial rigidity, affecting structural use space, main pipe cuts or weld damage, etc., to achieve long service life, Good seismic performance, high bearing capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

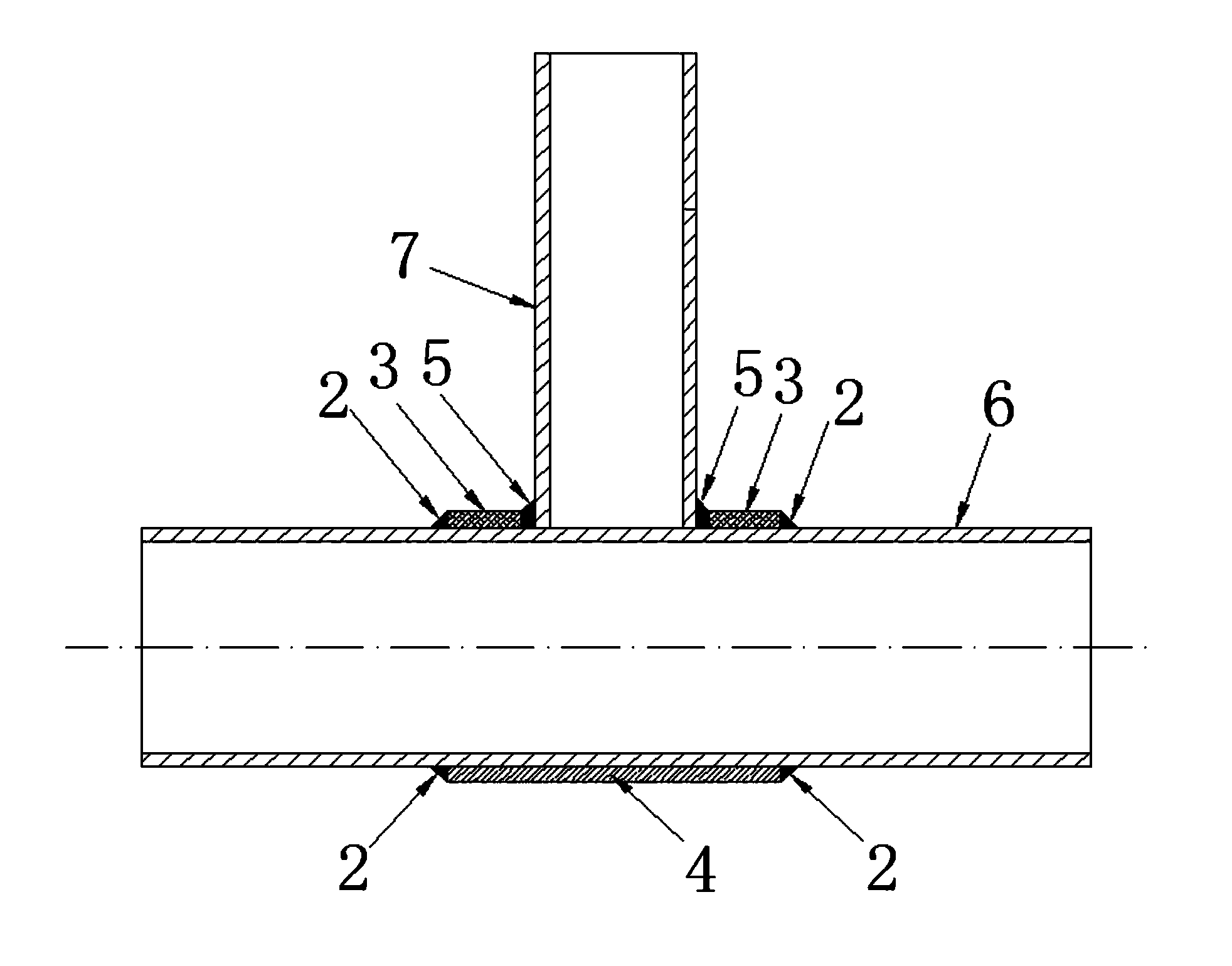

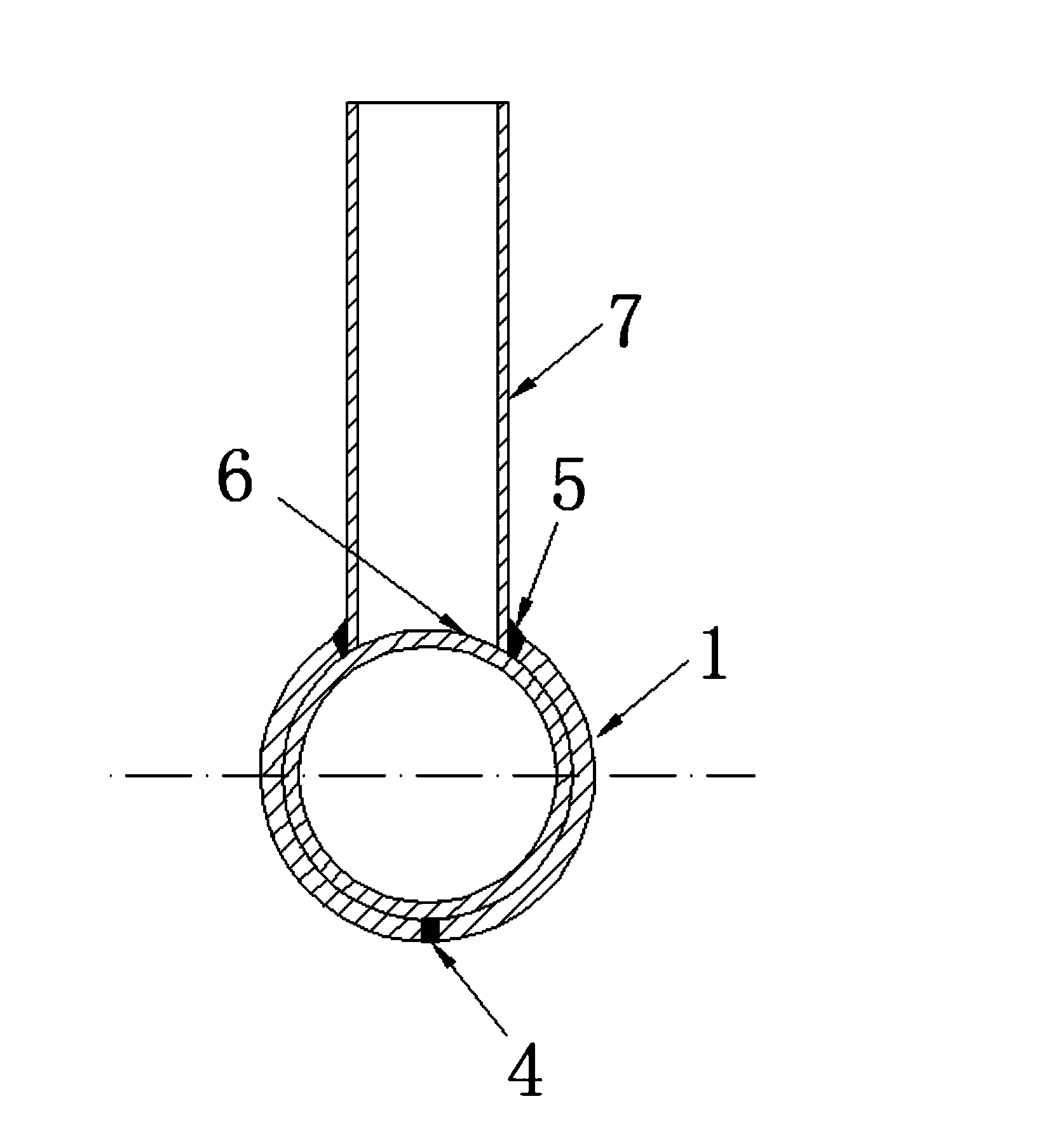

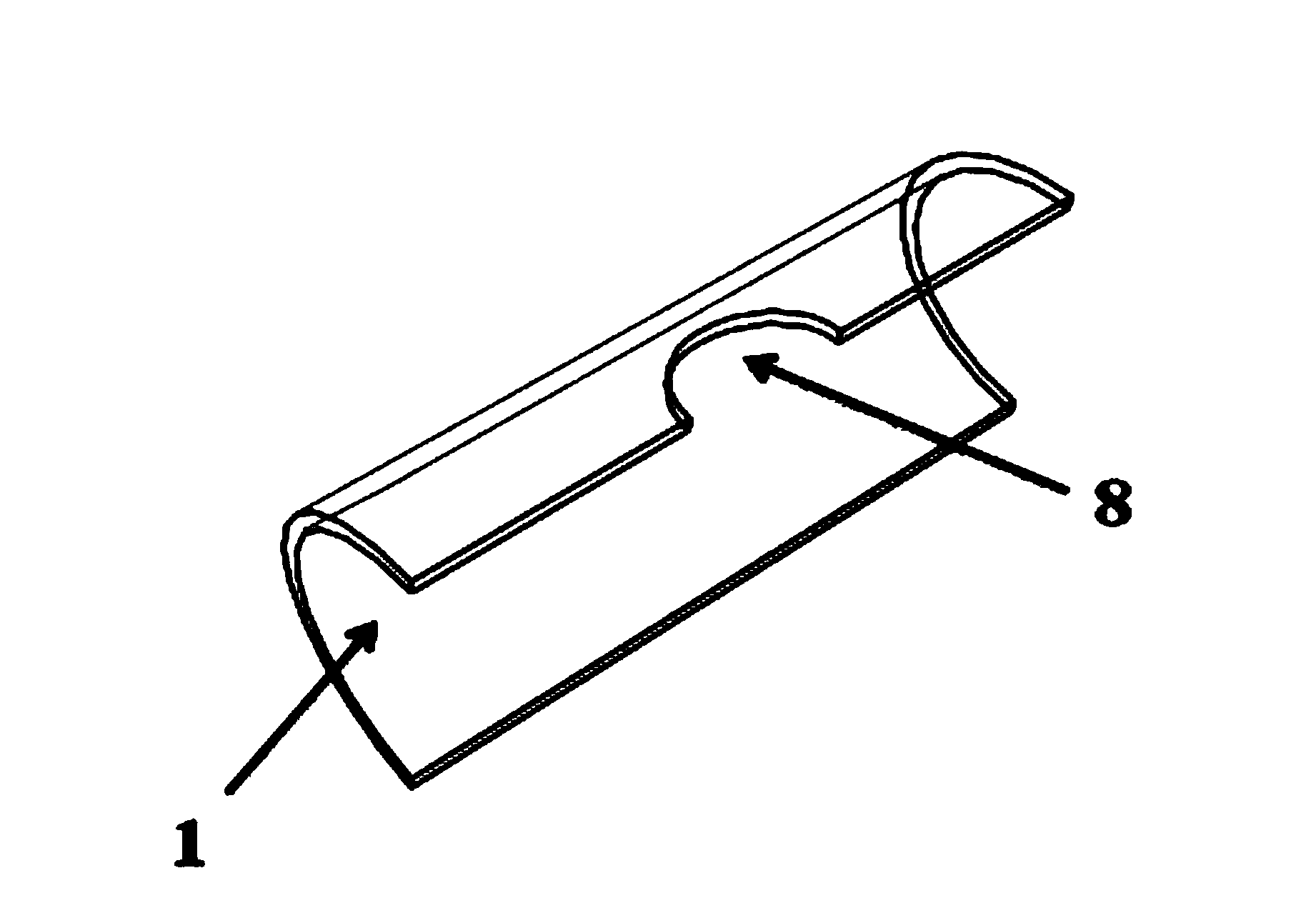

[0026] Such as Figure 1 to Figure 3 As shown in the figure, a ring sleeve used to reinforce intersecting joints of steel pipe trusses includes two semicircular ring sleeves 1, and the middle part of a straight edge of each ring sleeve 1 is provided with a The orifice 8 where the reinforced node main pipe 6 and the reinforced node branch pipe 7 intersect coincides with each other, and the two orifices 8 are butted to form a round hole; the reinforced node branch pipe 7 is welded on the reinforced node main pipe 6, and forms T-shaped pipe node; the two annular sleeves 1 are respectively clamped on the main pipe 6 of the reinforced node, and the orifices 8 of the two annular sleeves 1 are respectively clamped on the branch pipe 7 of the reinforced node; Two annular sleeves 1 are butted together to form an upper surface butt weld 3 and a lower surface butt weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com