Run-through inner dumping method between mining areas for opencast coal mine during period of diversion

A technology for open-pit coal mines and mining areas, which is applied in the field of coal mining and quarrying, and can solve problems such as complex layout of trenches and pit lines, increased transportation distance of stripped objects, and increased stripping costs, so as to reduce the amount of secondary stripping and shorten stripping The effect of material transportation distance and saving transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

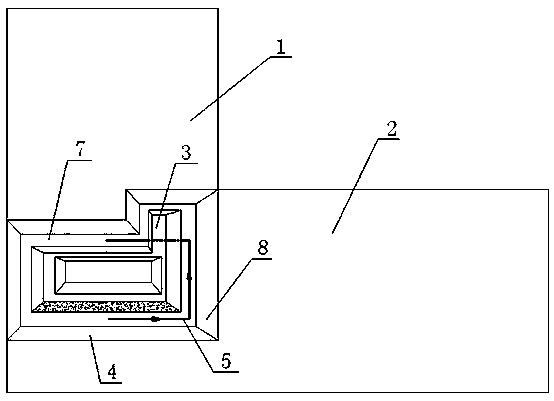

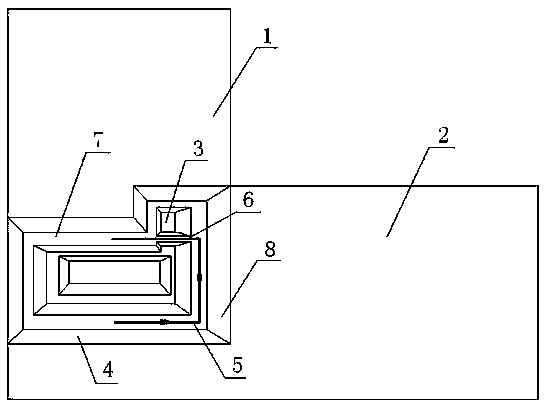

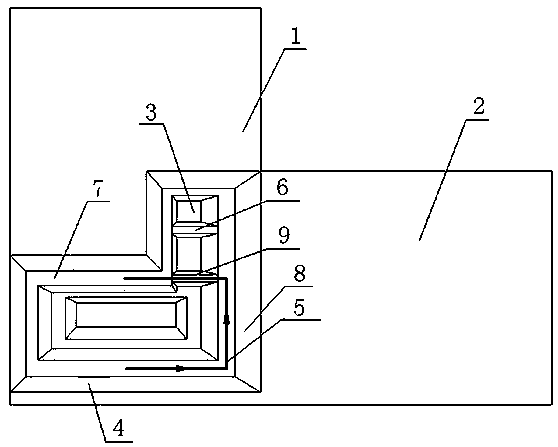

[0019] Such as Figure 2 to Figure 4 shown (in Figure 2 to Figure 4 The lower direction is the front direction), the method of connecting the inner row of the mining area during the turning period of this open-pit coal mine includes the following steps:

[0020] A. When mining area 1 advances to the terminal, and then begins to transition to mining area 2 during transition, a trapezoidal gob ditch 3 is reserved in the overlapping area of mining area 1 and mining area 2;

[0021] B. Ⅰ The working side 4 of the mining area advances forward, and the length of the trapezoidal gob ditch 3 increases continuously;

[0022] C. Build an intermediate bridge I6 on the trapezoidal mined-out ditch 3, connect the inner dump site 7 and the working side 8 of the mining area II, and pass through the interrupted side-side transportation line 5 to realize double-ring internal drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com