Opposed piston pump

A technology of opposing pistons and inner pistons, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc., can solve the problem that the plunger space is not fully utilized, weakens the sealing performance of the plunger and the swash plate, and reduces the size of the plunger. Effective length and other issues, to achieve the effect of improving service life, large displacement, and reducing displacement fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

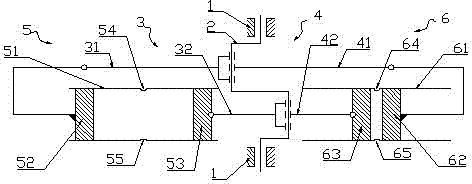

[0020] The opposed piston pump in this example is figure 1 As shown, the opposed piston pump includes a support base (1), a crankshaft (2), a first connecting rod group (3), a second connecting rod group (4), a first cylinder body (5) and a second cylinder body ( 6). Both ends of the crankshaft (2) are supported by the supporting base (1); the first cylinder block (5) and the second cylinder block (6) are opposite to the two sides of the crankshaft (2), forming a set of opposing cylinder blocks; the first The cylinder body (5) is provided with a cylinder body shell (51), an oil inlet hole (54), an oil outlet hole (55) and an inner piston (53) and an outer piston (52) reciprocating in the cylinder body; the second cylinder The body (6) is provided with a cylinder shell (61), an oil inlet hole (64), an oil outlet hole (65) and an inner piston (63) and an outer piston (62) reciprocating in the cylinder body; the first cylinder body (5) corresponds to the first connecting rod g...

Embodiment 2

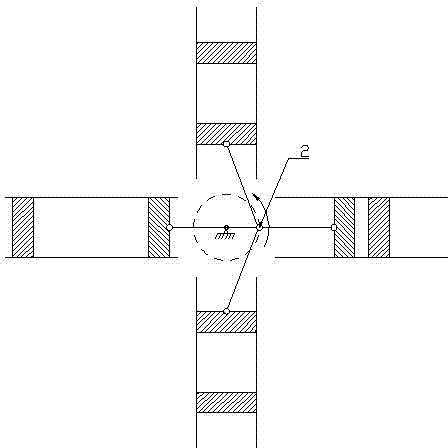

[0023] The opposed piston pump in this example is figure 2 , on a plane perpendicular to the crankshaft (2), two sets of opposed cylinders are distributed along the circumference of the crankshaft (2), with an interval of 90 degrees between adjacent cylinders, two sets of opposed cylinders correspond to the same set of crankshaft journals, and the rest are implemented in the same way example one.

Embodiment 3

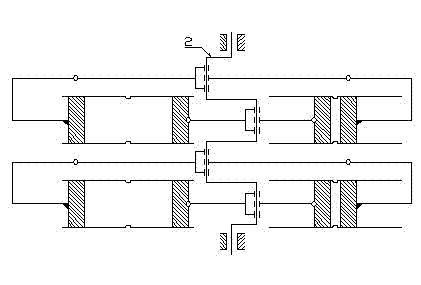

[0025] The opposed piston pump in this example is image 3 , in the axial direction of the crankshaft (2) two sets of opposing cylinder blocks are connected in series to form two upper and lower stages of opposing cylinder blocks, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com