Shaft sleeve type cross shaft

A cross shaft and cross shaft frame technology, applied in the field of transmission shafts, can solve the problems of complex structure, easy wear, and inconvenient installation of the transmission cross shaft, and achieve the effects of good sealing effect, improved service life and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

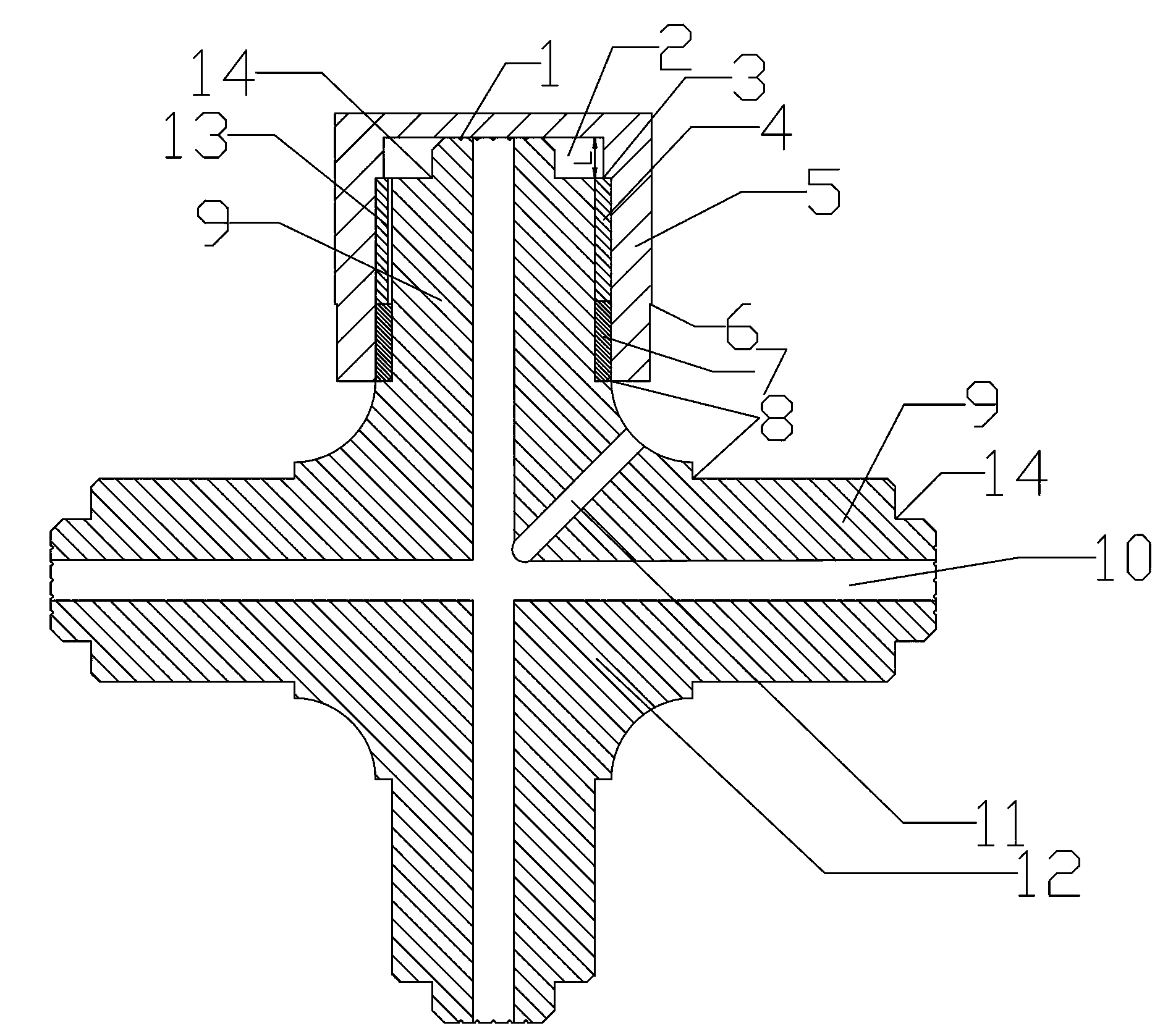

[0014] see figure 1 , the present invention has a cross shaft frame 12, a cross oil passage 10 is opened in the cross shaft frame 12, and an oil inlet passage 11 is opened in the cross shaft frame 12 to communicate with the cross oil passage 10, and each of the four shaft heads 9 is fitted There are sealing rings 7, shaft sleeves 4 and shaft sleeve seats 5, which are characterized in that: a stop shaft shoulder 8 is provided at the rear end of each shaft head 9, the front end of the shaft head has a stepped structure 14, and the inner circle of the shaft sleeve 4 There are 4 oil grooves 13 on the surface (generally 3-5, not less than 1); the sealing ring 7 is installed against the stop shoulder 8 of the shaft head 9, and the shaft sleeve 4 and the shaft head 9 Clearance assembly, shaft sleeve 4 and shaft sleeve seat 5 are interference fitted, shaft sleeve seat 5 and shaft head 9 step surface form oil storage chamber 2, and oil groove 13 on the shaft sleeve 4 is in communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com