Impact reducing tail-section linear explosion separating device for small-diameter assisted takeoff rocket

An explosive separation and small-diameter technology, which is applied in the direction of projectiles, self-propelled bombs, and offensive equipment, can solve problems such as difficulty in meeting batch production requirements, affecting the normal operation of surrounding equipment, difficulty in installation, operation, and inspection, and achieves improved separation The effect of safety, small structure size and low separation impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

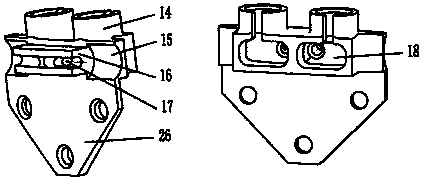

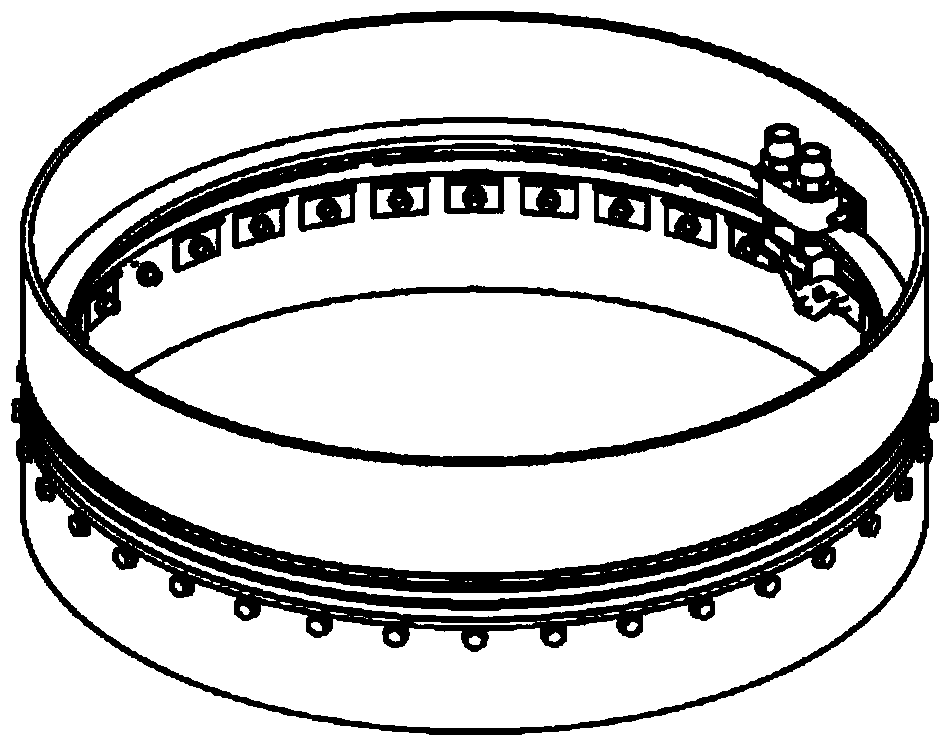

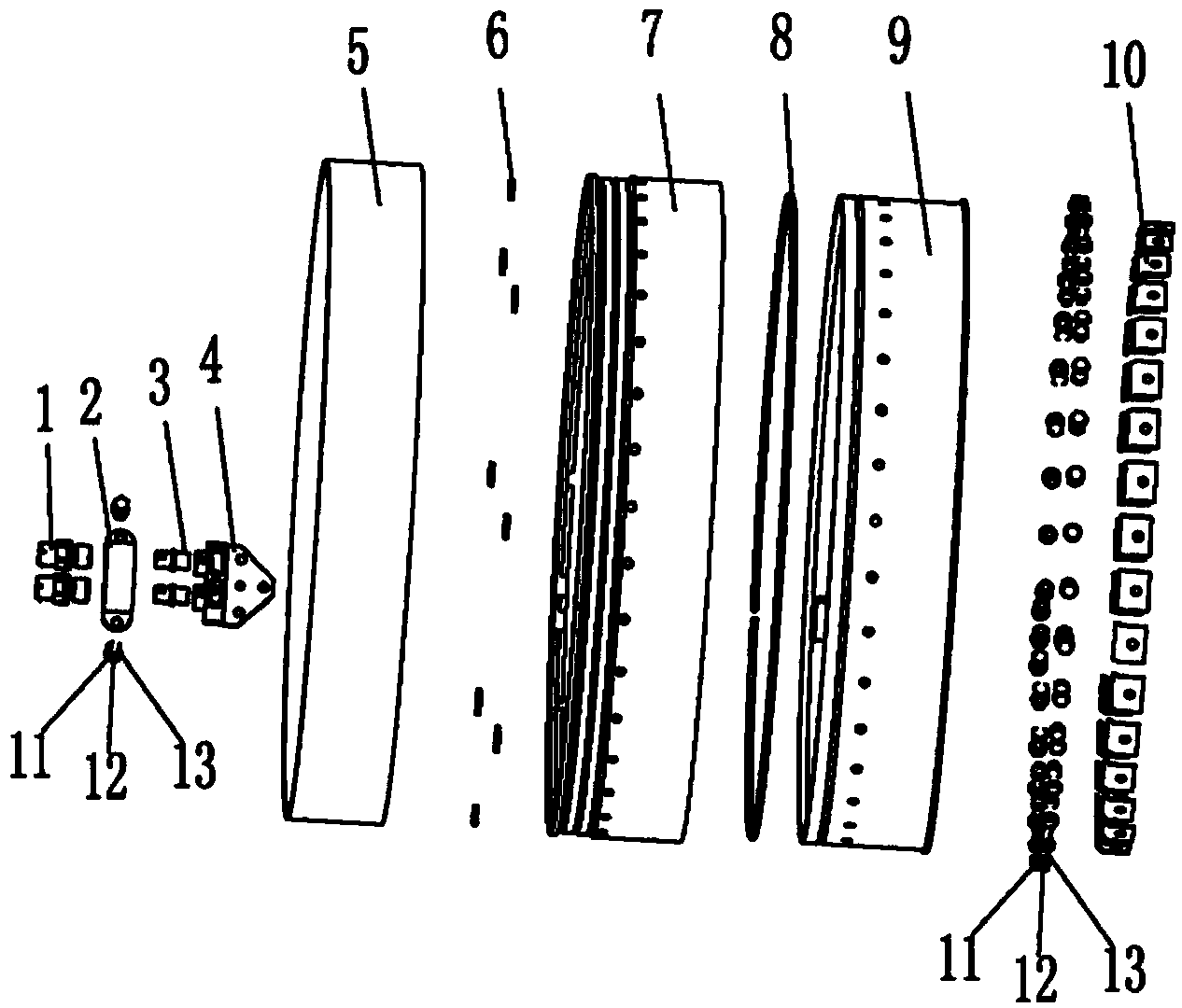

[0036] Such as figure 1 Shown is the schematic diagram of the structure of the linear explosive separation device of the present invention, figure 2 Shown is an exploded view of the structure of the linear explosive separation device of the present invention, image 3 It is a cross-sectional structure diagram of the detonation position of the linear explosive separation device of the present invention, Figure 4 It is a cross-sectional structure diagram of the non-initiation position of the linear explosive separation device of the present invention. It can be seen from the figure that the explosive separation device of the present invention includes a detonator 1, a split detonation joint, a shock-reducing shell, an explosive cable 8, a glass protective cover 9, and an energy-absorbing pad 10. Bolts 11, flat washers 12 and nuts 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com