Integrated shield and protection sensor

A technology that integrates sensors and shielding protection, applied to instruments, measuring devices, etc., can solve the problems of real-time detection failure, abnormality, deviation from the actual detection value, etc., and achieve the effect of improving the performance of shielding protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

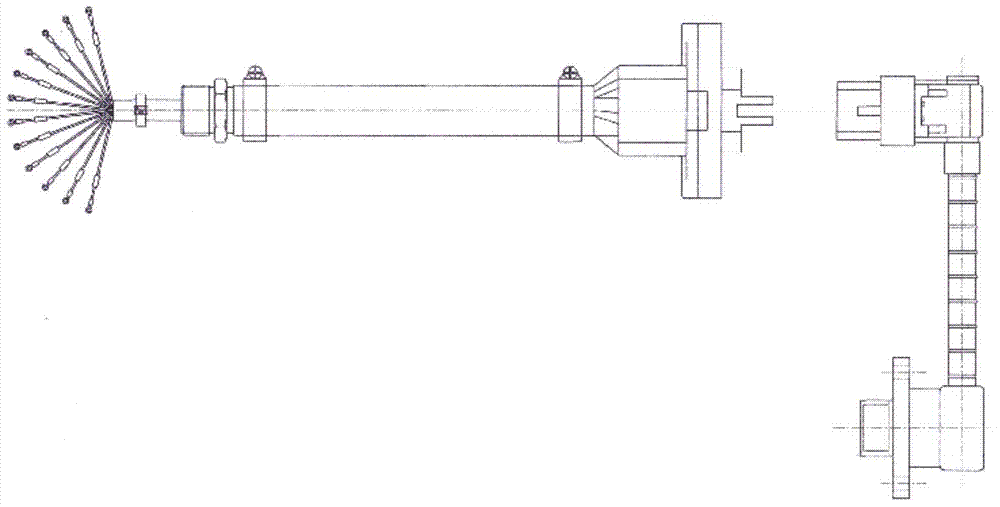

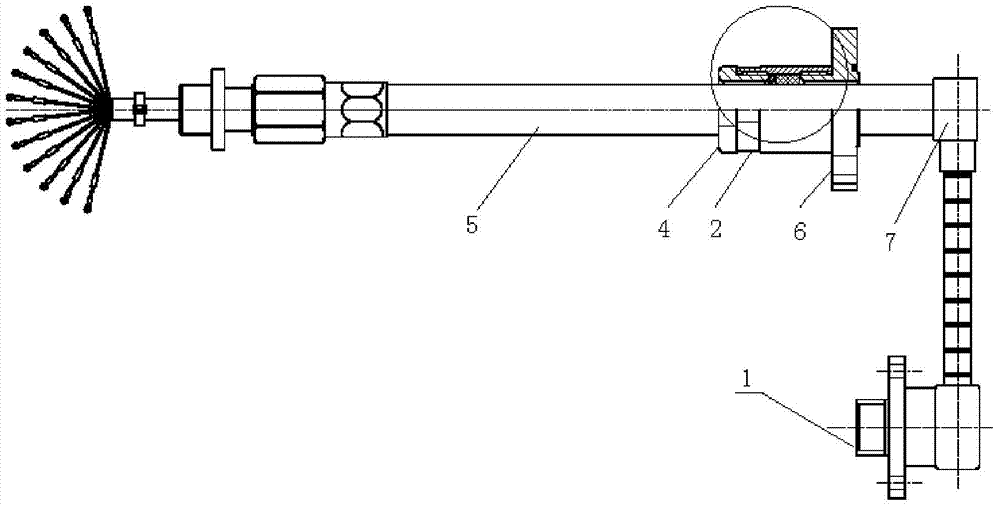

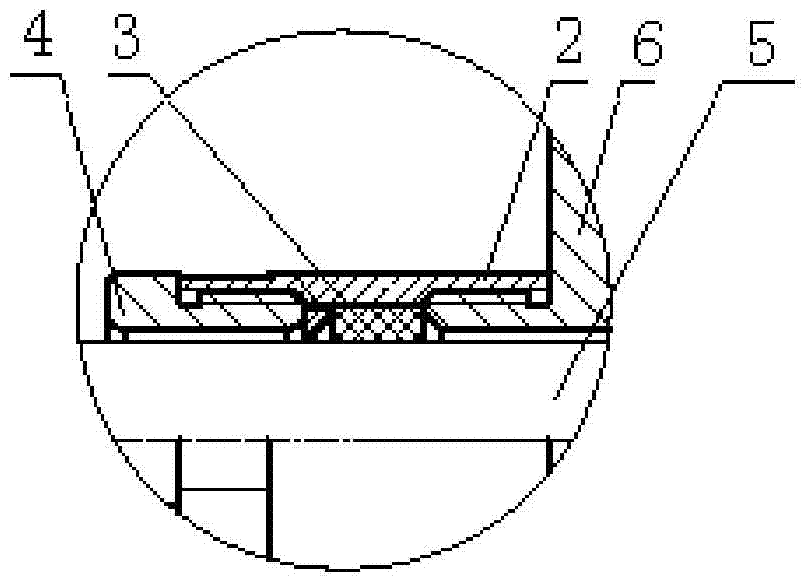

[0009] The shielding protection type integrated integrated sensor disclosed in the patent application of the present invention includes a sensing probe 1 and its fixing seat, a cable part 5 and a sealing connection flange, and the cable part 5 is composed of a signal transmission cable for sensing and transmitting signals and an external part of the cable. The cable sheath is formed, and the cable sheath is usually a rubber sheath. This embodiment is described by taking the installation of a high-speed train axle box as an example. The flange seat 6 of the sealing connection flange is sealed and fixedly installed on the axlebox box with built-in sensors, and the sealing sleeve 2 is detachably fixed on the chassis of the flange seat 6, and its detachable fixing structure includes screw connection and buckle fixing Connections, etc., 1 sealing sleeve 2 is threaded to connect the gland 4, the sealing sleeve 2 between the gland 4 and the flange seat 6 has a built-in sealing sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com