A kind of preparation method of redispersible fluoropolymer latex powder

A polymer latex and redispersion technology, applied in the production of bulk chemicals, etc., can solve the problems of difficulty in controlling the molecular weight and molecular structure of latex powder, poor water and oil repellency on the surface of the modified coating film, and failure to meet practical applications. Excellent dispersion stability, excellent chemical resistance and water and oil repellency, effect of small van der Waals radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

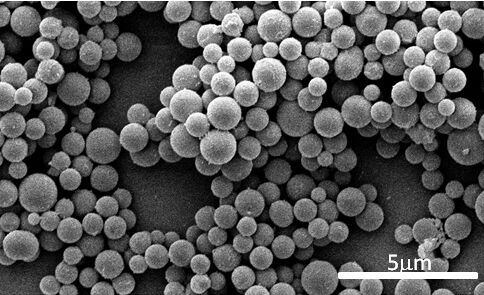

Image

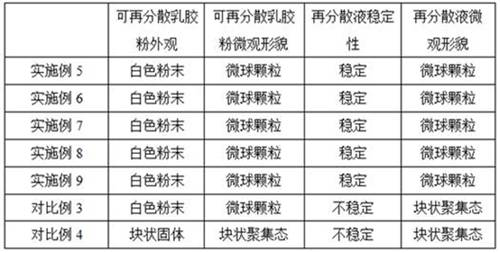

Examples

Embodiment 1

[0029] Preparation of fluorine-containing macromolecular chain transfer agent with hydrophilic groups: In a 500ml single-mouth bottle, add 3.00 g of hydrophilic oligomer polyethylene glycol monomethyl ether 1000 (mPEG1000), 2.27 g of small molecule chain transfer agent S- 1-dodecyl-S'-(α,α'-dimethyl-α"-propionic acid) trithioester, 7.6×10 -2 g dehydrating agent dicyclohexylcarbodiimide, 4.5×10 -2 g catalyst 4-dimethylaminopyridine, 40 mL solvent dichloromethane, reacted for 48 h under nitrogen protection. After the reaction, it was filtered by suction, concentrated, precipitated with anhydrous ether, and dried in a vacuum oven at 30°C. The obtained light yellow solid product was the macromolecular chain transfer agent mPEG 1000 -CTAs.

[0030] Take 0.175 g macromolecular chain transfer agent mPEG successively 1000 -CTA, 2.00 g dodecafluoroheptyl methacrylate monomer, 7.8×10 -3 Add g initiator azobisisobutyronitrile and 8.00 g solvent tetrahydrofuran into a 50ml single-n...

Embodiment 2

[0032] Preparation of fluorine-containing macromolecular chain transfer agent with hydrophilic groups: In a 500ml single-mouth bottle, add 5.00 g of hydrophilic oligomer polyethylene glycol monomethyl ether 2000 (mPEG2000), 2.27 g of small molecule chain transfer agent S- 1-dodecyl-S'-(α,α'-dimethyl-α"-propionic acid) trithioester, 7.6×10 -2 g dehydrating agent dicyclohexylcarbodiimide, 4.5×10 -2 g catalyst 4-dimethylaminopyridine, 40 mL solvent dichloromethane, reacted for 48 h under nitrogen protection. After the reaction was completed, it was filtered by suction, concentrated, precipitated with anhydrous ether, and dried in a vacuum oven at 30°C. The obtained light yellow powder product was the macromolecular chain transfer agent mPEG 2000 -CTAs.

[0033] Take 0.305 g macromolecular chain transfer agent mPEG successively 2000 -CTA, 2.00 g of dodecafluoroheptyl methacrylate monomer, 7.8×10-3 g of initiator azobisisobutyronitrile and 8.00 g of solvent tetrahydrofuran wer...

Embodiment 3

[0035] Preparation of fluorine-containing macromolecular chain transfer agent with hydrophilic groups: In a 500ml single-mouth bottle, add 12.00 g of hydrophilic oligomer polyethylene glycol monomethyl ether 5000 (mPEG5000), 2.27 g of small molecule chain transfer agent S- 1-dodecyl-S'-(α,α'-dimethyl-α"-propionic acid) trithioester, 7.6×10 -2 g dehydrating agent dicyclohexylcarbodiimide, 4.5×10 -2g catalyst 4-dimethylaminopyridine, 40.00 mL solvent dichloromethane, reacted for 48 h under nitrogen protection. After the reaction, it was filtered by suction, concentrated, precipitated with anhydrous ether, and dried in a vacuum oven at 30 °C to obtain a light yellow powder product, the macromolecular chain transfer agent mPEG 5000 -CTAs.

[0036] Take 0.795 g macromolecular chain transfer agent mPEG successively 5000 -CTA, 2.50 g of dodecafluoroheptyl methacrylate monomer, 7.8×10-3 g of initiator azobisisobutyronitrile and 8.00 g of solvent tetrahydrofuran were added to a 50m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com