A kind of water-based rust conversion shielding coating and preparation method thereof

A barrier coating, water-based technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of long construction period, adverse effects of coating workability, difficult removal of metal surface, etc., to improve workability, improve salt spray resistance, improve The effect of anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

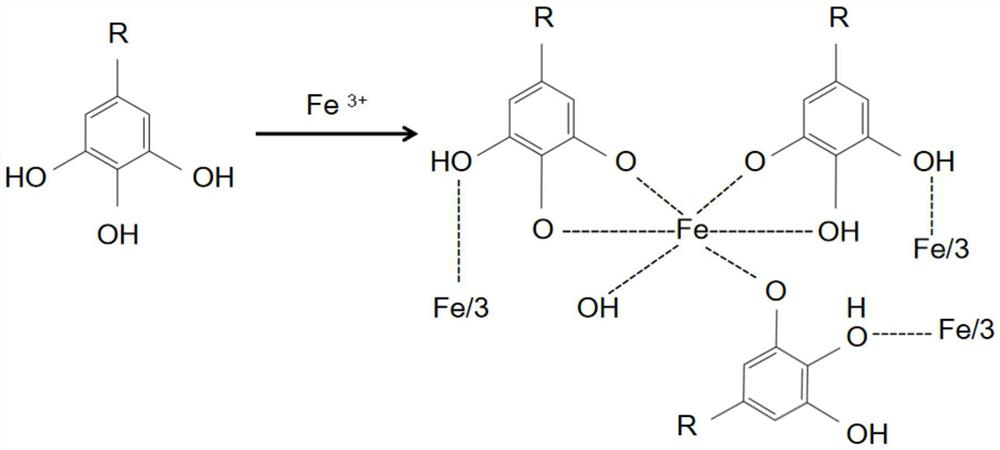

Method used

Image

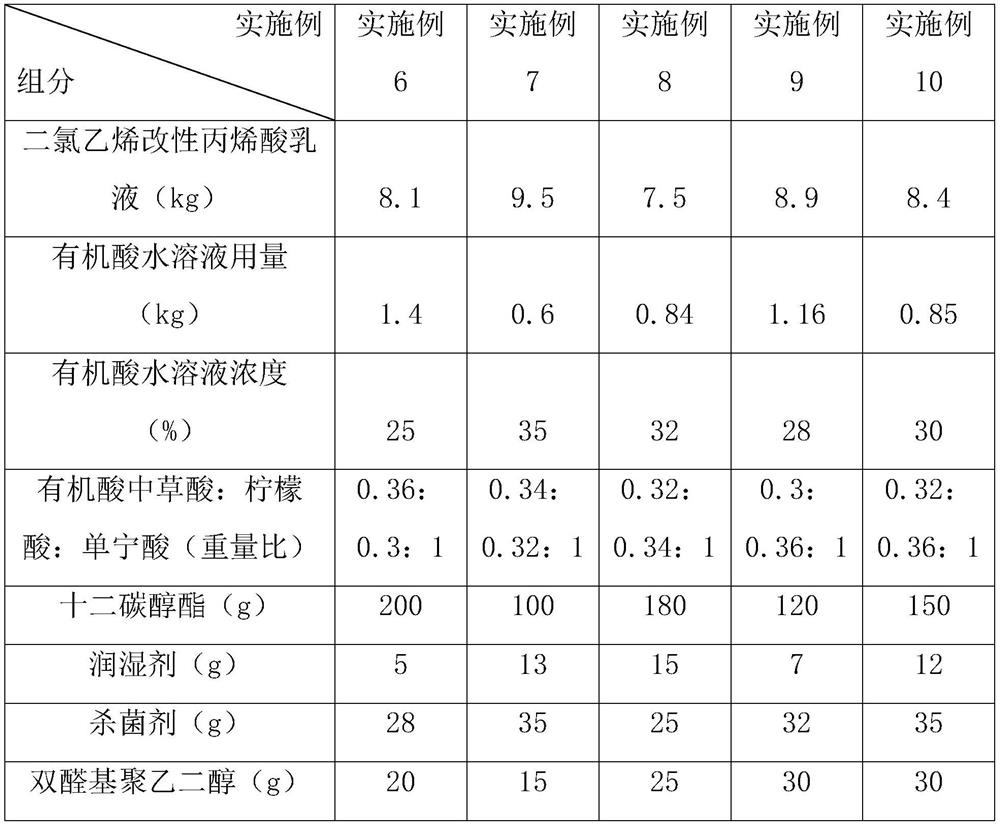

Examples

Embodiment 1

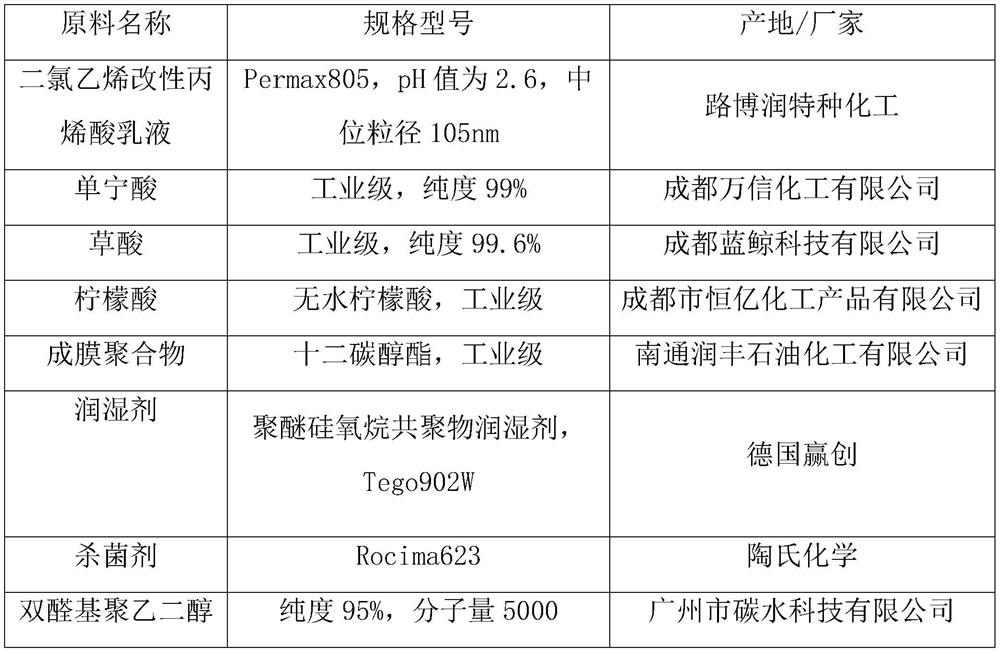

[0039] Embodiment 1: the preparation method of water-based rust conversion shielding coating, comprises the steps:

[0040] The tannic acid and water were taken to prepare the tannic acid aqueous solution with a mass concentration of 30%. Take 8.5kg of vinylidene chloride modified acrylic emulsion, add 150g of dodecyl alcohol ester film-forming polymer, 10g of wetting agent and 1kg of tannic acid aqueous solution in turn, and stir at 800 rpm for 30min to obtain water-based rust conversion Barrier paint.

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that in Example 2, an organic acid aqueous solution with a mass concentration of 30% is used instead of the tannic acid aqueous solution. The weight ratio of 0.1 is the same as that of Example 1.

Embodiment 3

[0044] The difference between Example 3 and Example 2 is that the ratio of each component in the organic acid of Example 3 is different. In Example 3, the organic acid is composed of tannic acid, oxalic acid, and citric acid in a weight ratio of 3:1:1 The composition is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com