Flow measuring device and method for non-full-flow pipe outlet

A technology of outlet flow and measuring device, which is applied to liquid level indicators for physical variable measurement, volume/mass flow generated by electromagnetic effects, etc., and can solve problems such as inconvenient portability, high price, and limited use of measuring equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0019] Provide the embodiment of the present invention below in conjunction with accompanying drawing as follows:

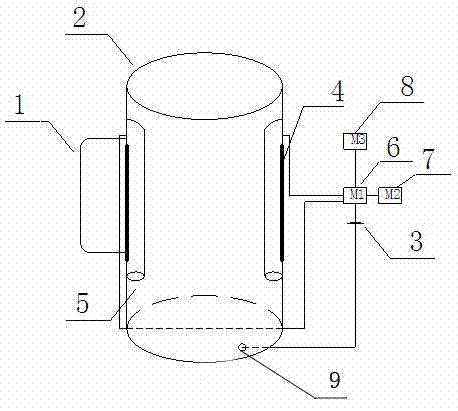

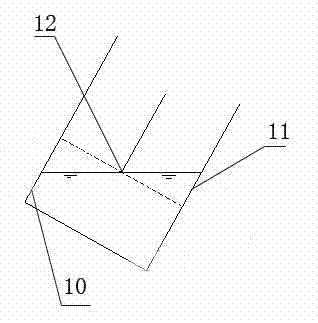

[0020] Such as figure 1 , figure 2 As shown, a non-full flow pipeline outlet flow measuring device according to the present invention is mainly composed of a handle 1, a measuring cup 2, a battery 3, a carbon electrode 4, a carbon electrode protection tube 5, a data processing module 6, and a display screen 7 , a thin film matrix keyboard 8; wherein the measuring cup 2 is a cylindrical container made of hard plastic with a sealed bottom and an upper opening; the bottom surface of the measuring cup 2 is provided with a wire connection point 9, which is connected to the upper end of the carbon electrode 4 through the battery 3 The handle 1 is installed on the outside of the measuring cup 2; the two carbon electrodes 4 are respectively bonded on the tube walls of the two carbon electrode protective tubes 5 which are protected by hard plastic tubes, and the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com