Leak detection method for a floating air bag

A technology of leak detection and air bag, which is applied in the field of leak detection, can solve the problems of gas leakage due to the stress concentration of the bag body, affect the service life of the aerostat, and cannot realize accurate detection, etc., and achieve low cost, novel test principle and short cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

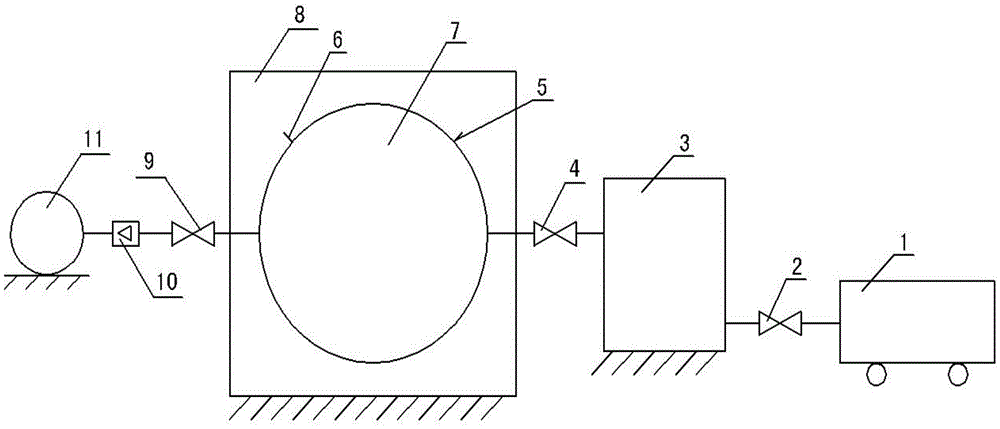

[0027] The leakage detection method of the floating air bag in the present embodiment is carried out in the following steps:

[0028] Step 1, set the initial state as follows: airbag temperature Tc is 20°C, airbag pressure Pc is 100kPa, airbag volume Vc is 10m 3 , the gas in the airbag is air, helium or hydrogen.

[0029] Step 2, by controlling the flowmeter to make the airbag leak quantitatively into the external gas tank, set the gas volume of the quantitative leakage as ΔV 0 , and the leaked gas volume of the airbag obtained by detection is ΔV 0 After that, the airbag pressure is P 0 , the airbag temperature is T 0 ;Set the gas volume of quantitative leakage as ΔV 0 , and ΔV 0 Not more than 1m 3 .

[0030] Step 3, in the same initial state as Step 1, change the gas volume of the quantitative leakage as ΔV 1 ,...,ΔV n , and ΔV 0 ≠ΔV 1 ≠…≠ΔV n , repeat step 2, and obtain the leaked gas volume of the airbag as ΔV 1 ,...,ΔV n After that, the airbag temperature cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com