Magnetoelectric tachometric transducer and test device thereof

A speed sensor and sensor technology, applied in the field of magnetoelectric sensors, can solve the problems of low sensor reliability, pollution, damage to the measured body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

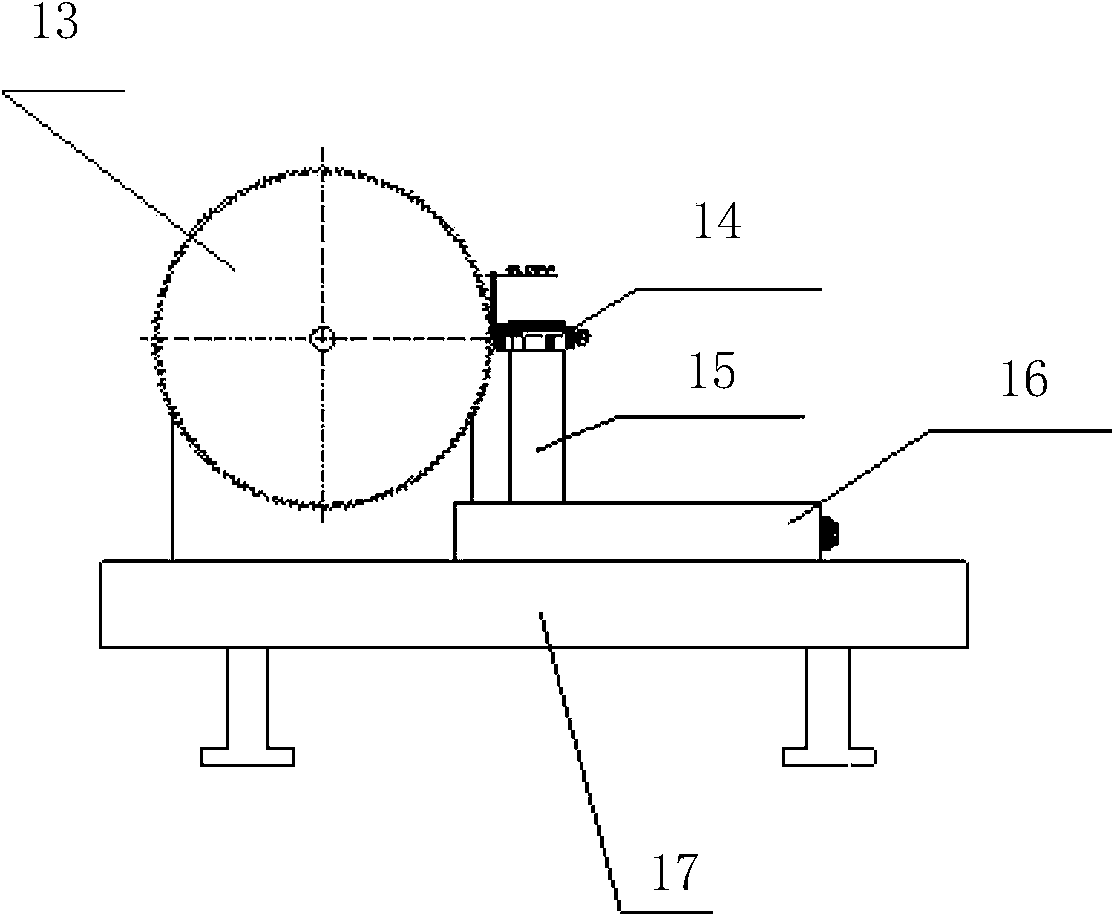

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

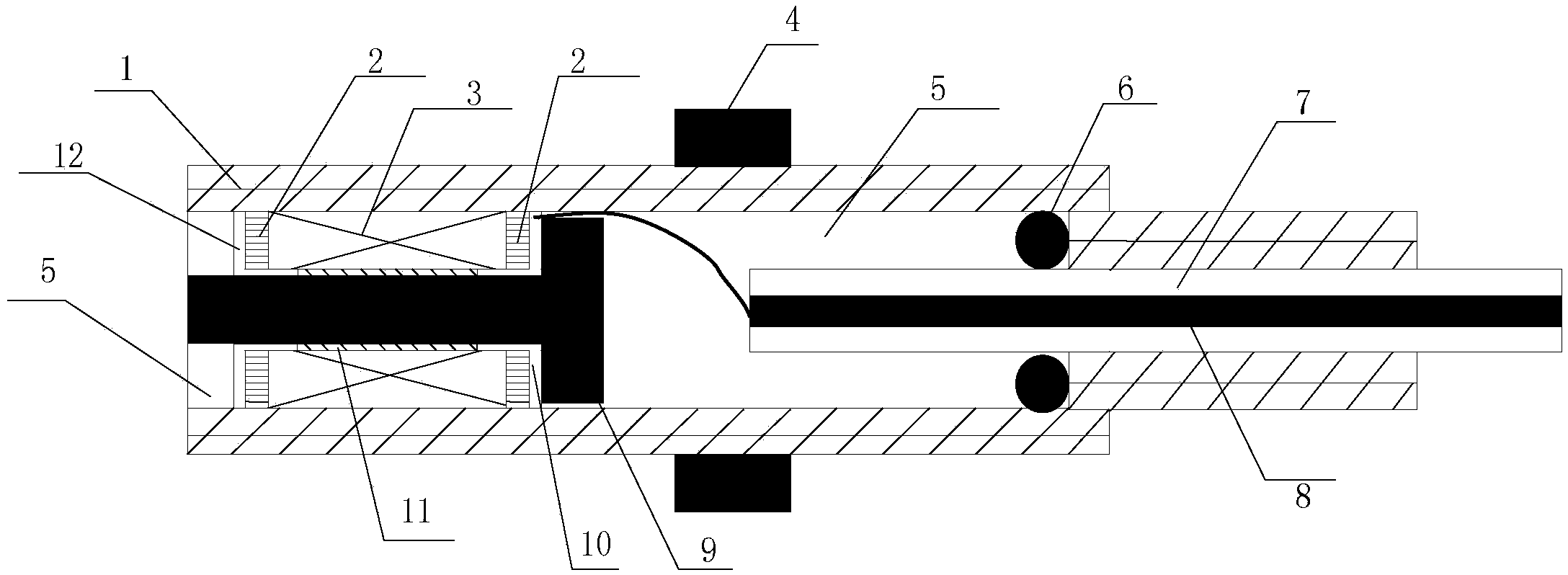

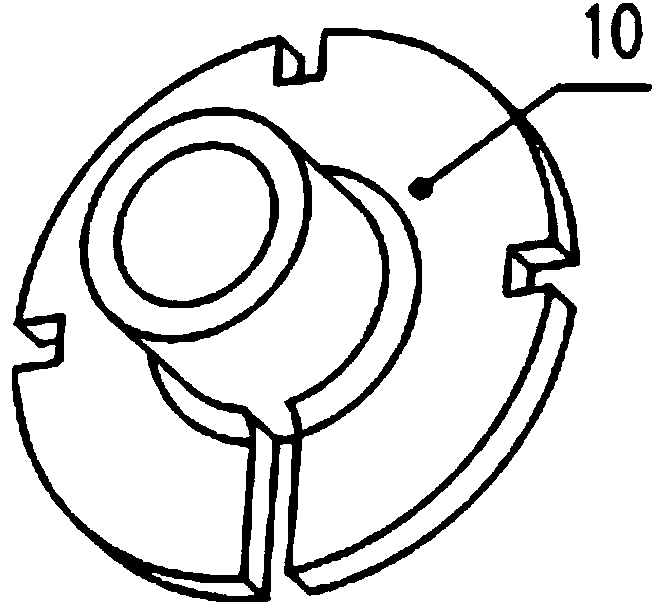

[0017] Such as figure 1 As shown, a magnetoelectric speed sensor includes a sensor injection molding body shell 1 and a sensor injection molding body, and the sensor injection molding body is provided with a coil skeleton 2, a coil 3, a nut 4, an epoxy resin filler 5, a sealing ring 6, and a sensor lead wire 7 , Iron core 9, inner half bobbin 10, heat shrink tube 11 and outer half bobbin 12. The coil 3 is wound in the middle of the bobbin 2, and the two ends of the bobbin 2 are provided with an inner half bobbin 10 and an outer half bobbin 12, and the small end faces of the inner half bobbin 10 and the outer half bobbin 12 extend into the middle of the I-shaped bobbin 2. In the through groove, the large end surfaces of the inner half bobbin 10 and the outer half bobbin 12 are in contact with the outer sides of both ends of the I-shaped bobbin 2; 10 and the small end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com