Device and method for measuring slip velocity at microscale

A technology of slip velocity and measurement method, applied in measurement devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of large amount of data and image analysis, accuracy impact, complexity, etc., to achieve convenient implementation and repeatability Good, easy to handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

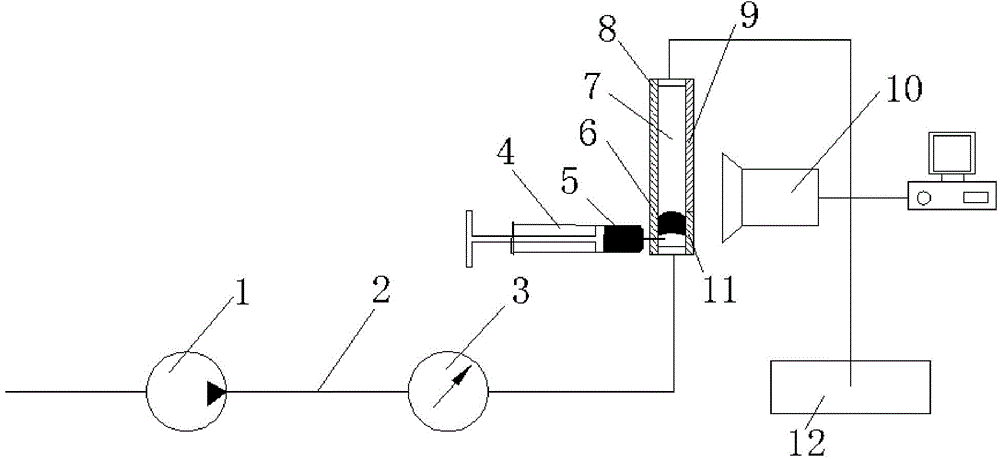

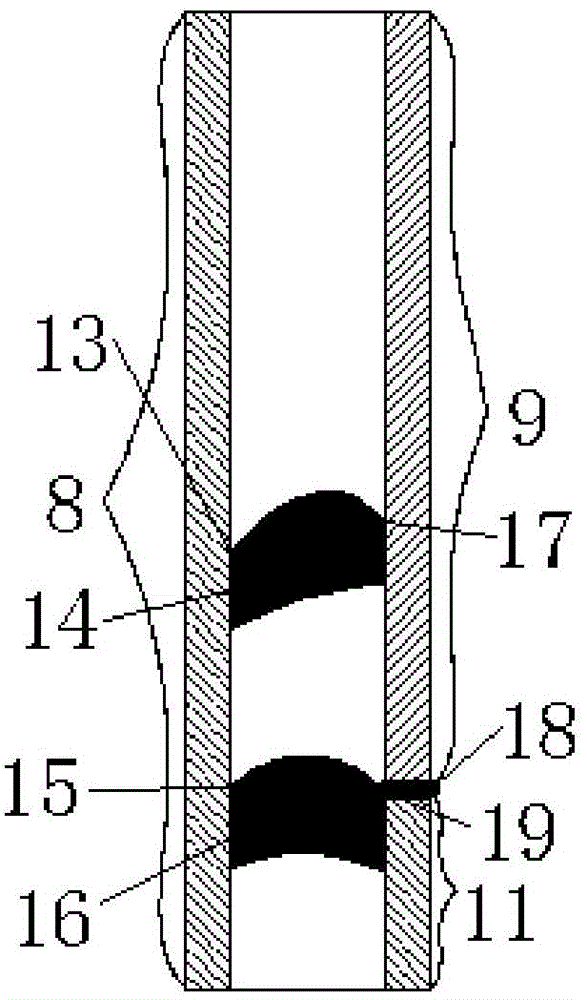

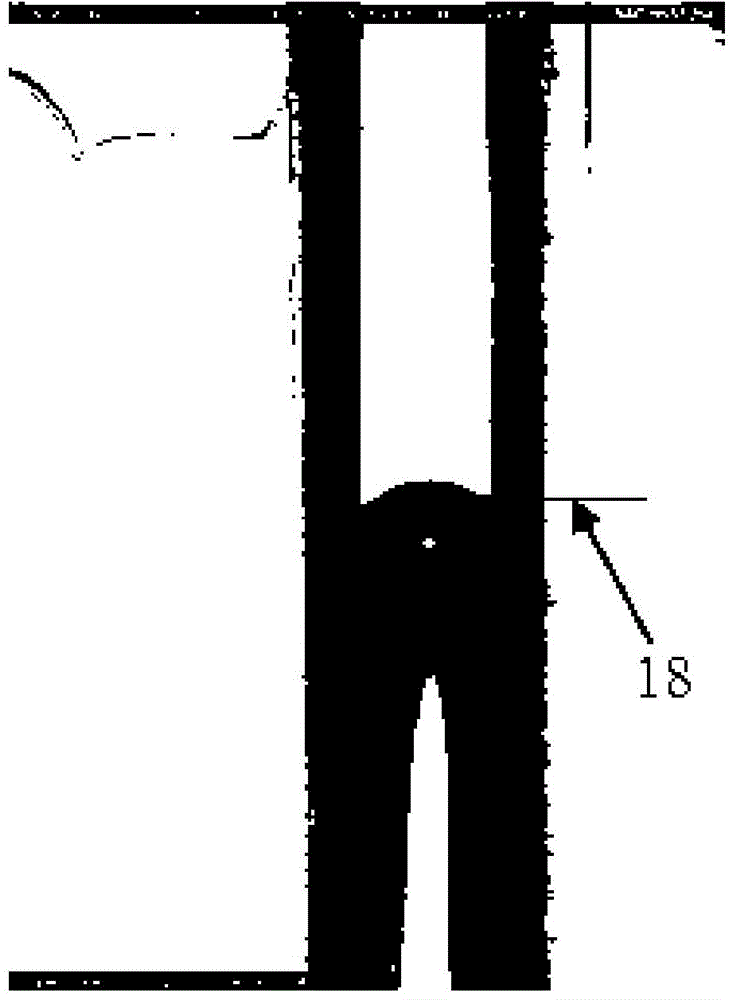

[0024] The device for measuring slip velocity at the microscale includes a micro-gas pump 1, a piping system 2, a barometer 3, a micro-injection pump 4, a liquid 5, a rectangular channel 7, a high-speed camera system 10, and a water tank 12. The left side wall of the rectangular channel 7 is Hydrophilic silicon wafer one 8, the right side wall is composed of two silicon wafers spliced up and down on the same plane, the lower silicon wafer is hydrophilic silicon wafer three 11, the upper silicon wafer is hydrophobic silicon wafer two 9, hydrophobic silicon wafer The length of the second 9 is three times that of the lower hydrophilic silicon wafer three 11, the front and rear side walls of the rectangular channel are transparent glass sheets, the distance between the left and right side walls of the rectangular channel 7 is 1mm, and the length and width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com