Moisture separator reheater and nuclear power plant

A steam-water separation and reheater technology, which is applied in nuclear power generation, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of equipment miniaturization and inability to effectively use the steam-water separation reheater, and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0030] [structure]

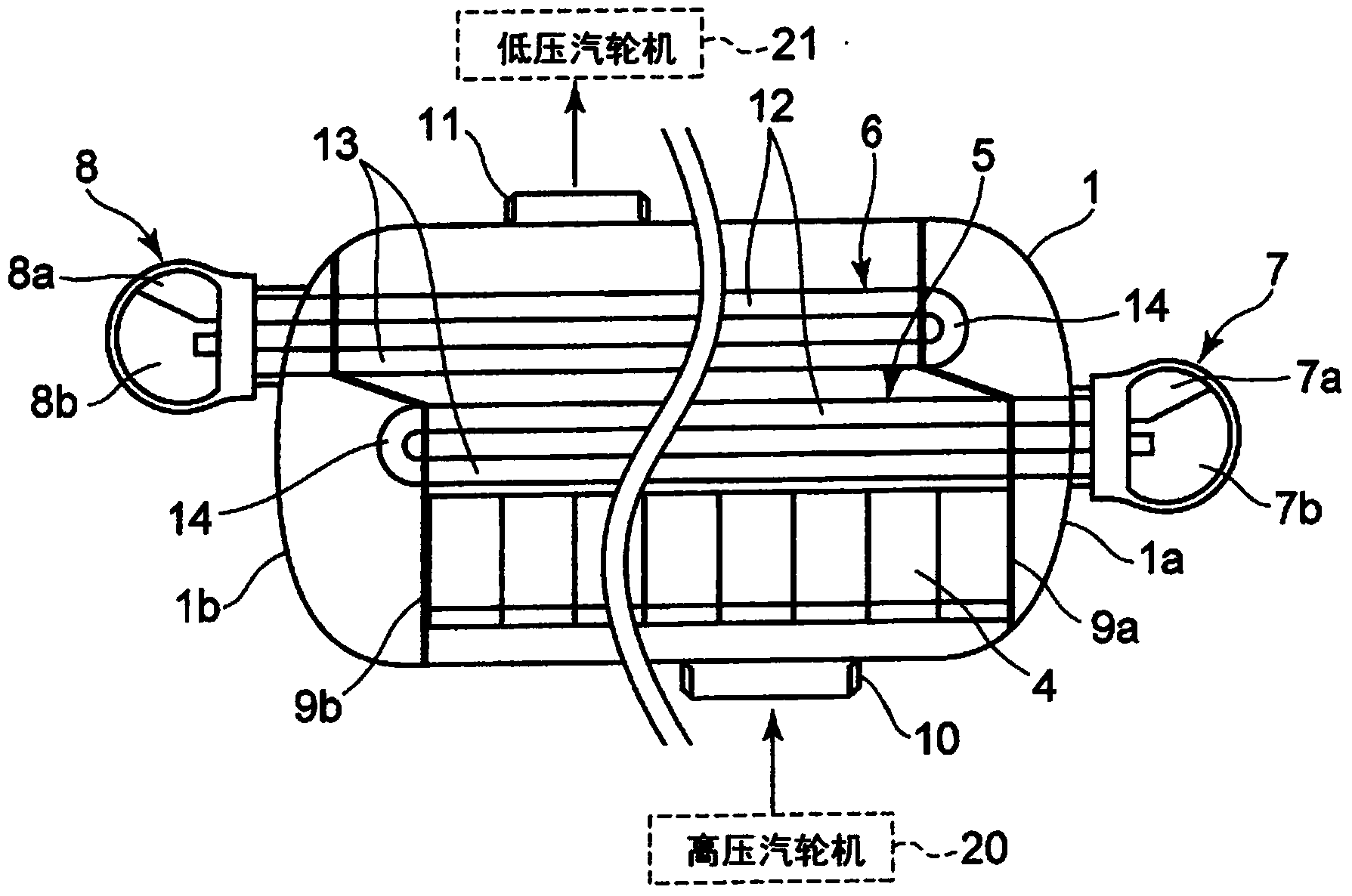

[0031] figure 1 It is a front schematic configuration view showing the first embodiment of the steam-water separator reheater according to the present invention.

[0032] The steam-water separation reheater of this embodiment is installed in nuclear power generation equipment, such as figure 1 As shown, the moisture of the humid steam discharged from the high-pressure steam turbine 20 is separated, and the heated steam separated from the moisture is reheated by exchanging heat with the heating fluid, and the reheated heated steam is supplied to the low-pressure steam turbine 21 and the like. .

[0033] The steam-water separation reheater of the present embodiment is provided with: a cylindrical main body container 1 which is arranged laterally in a horizontal manner in the longitudinal direction in an installed state with both ends in the longitudinal direction sealed by heads 1a and 1b; The lower steam-water separator 4 in the container 1; the first he...

no. 2 Embodiment approach )

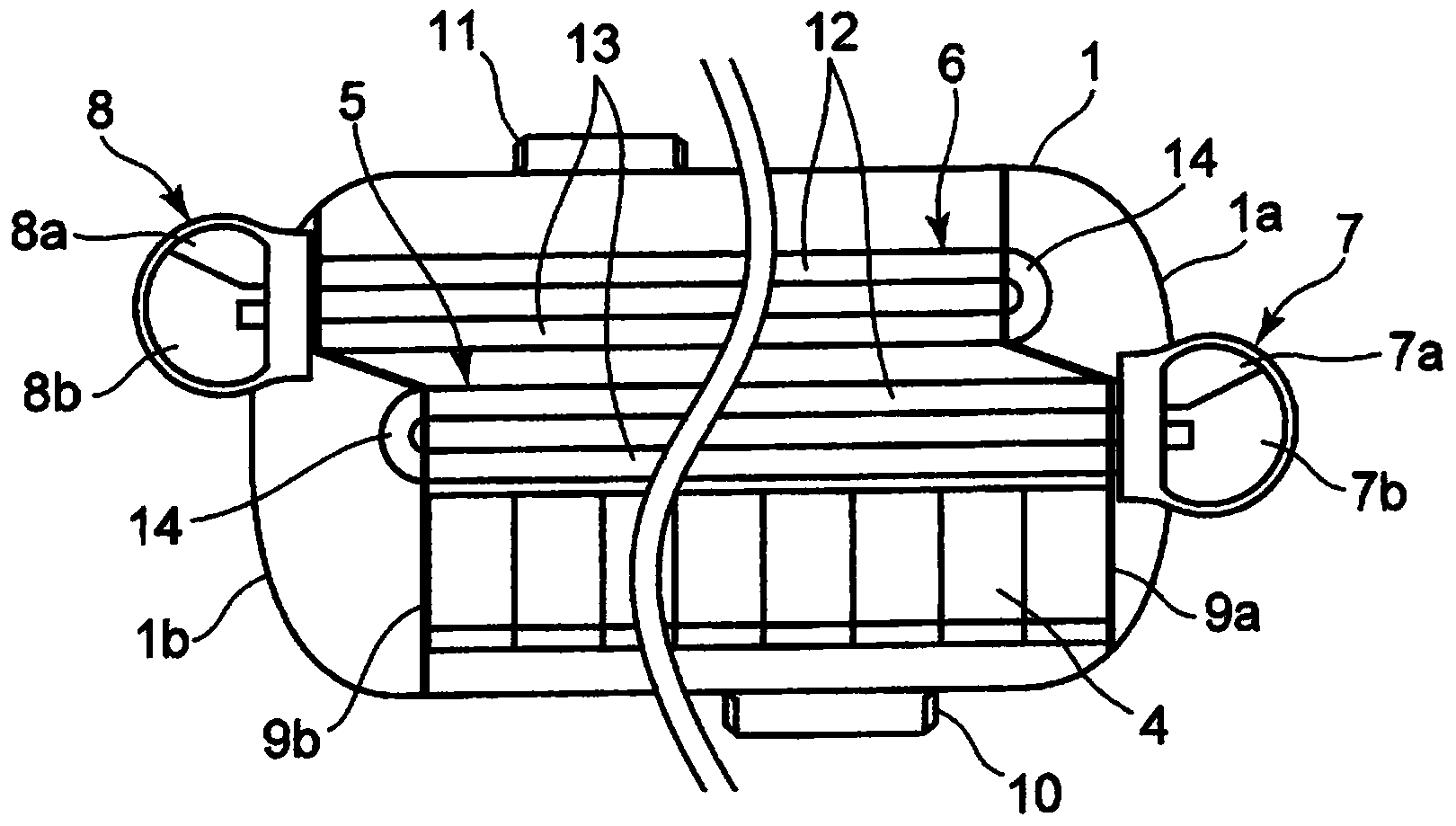

[0063] figure 2 It is a front schematic configuration view showing a second embodiment of the steam-water separator reheater according to the present invention. In addition, in the following embodiment, the same code|symbol is attached|subjected to the same part as the said 1st Embodiment, and overlapping description is abbreviate|omitted.

[0064] Such as figure 2 As shown, in the steam-water separator reheater of this embodiment, on the basis of the structure of the above-mentioned first embodiment, the first heater head 7 and the second heater head 8 are arranged to pass through the sealing heads 1a and 1b respectively. And it enters into the main body container 1 until it reaches the outer surface of a pair of partition plates 9a, 9b.

[0065] Therefore, the first heater head 7 and the second heater head 8 are installed in a state where only a part is exposed from the heads 1a, 1b.

[0066] Thus, according to the present embodiment, the first heater head 7 and the sec...

no. 3 Embodiment approach )

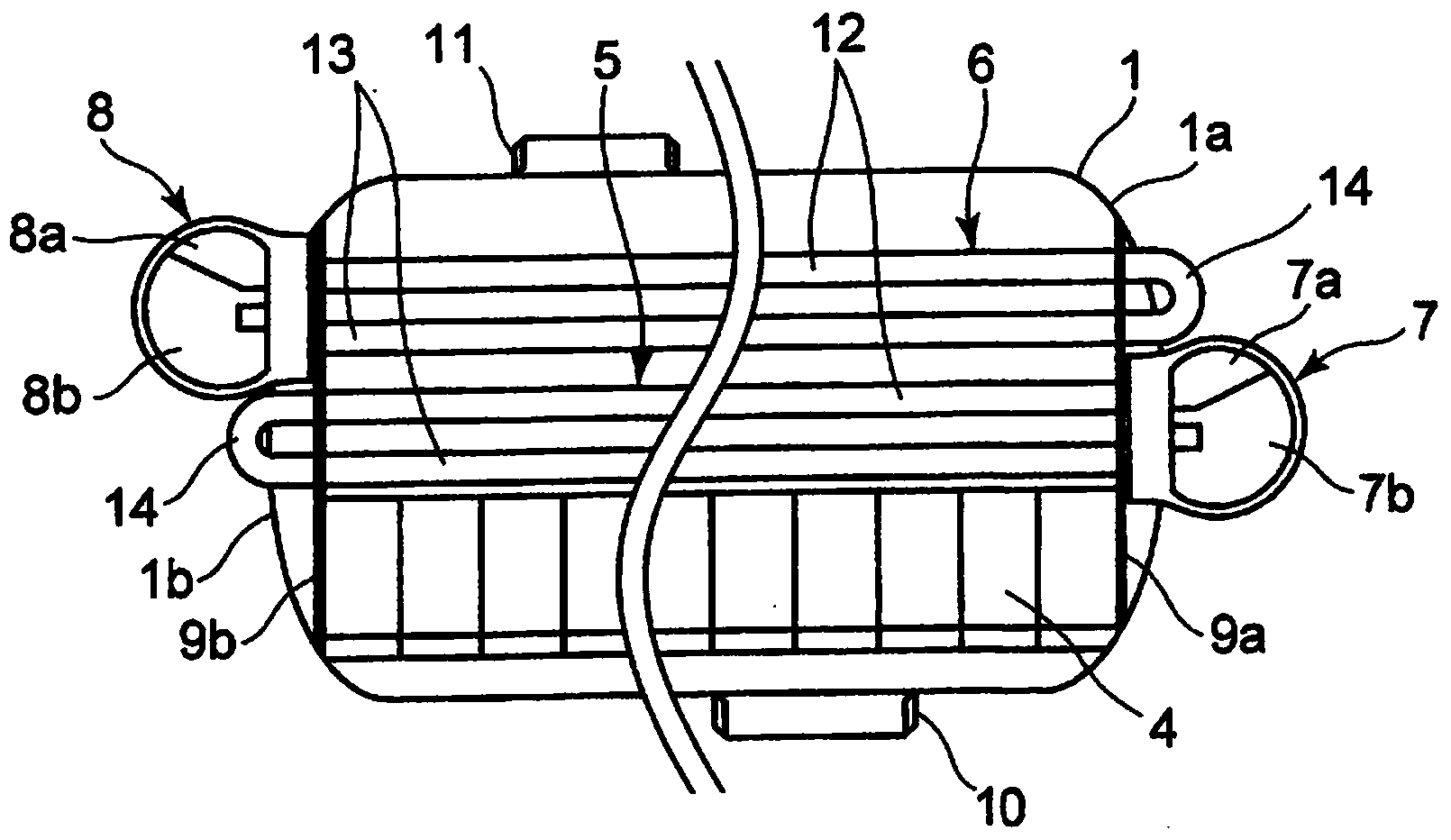

[0068] image 3 It is a front schematic configuration view showing a third embodiment of the steam-water separator reheater according to the present invention.

[0069] Such as image 3 As shown, in the steam-water separator reheater of this embodiment, on the basis of the structure of the above-mentioned second embodiment, the first heat transfer piping group 5 and the ineffective part of the second heat transfer piping group 6, that is, the curved pipe portion 14 are respectively Set on the outside of the head 1a, 1b. A pair of partitions 9 a, 9 b are provided in each of the heads 1 a, 1 b so that the heated vapor does not flow into the curved pipe portion 14 .

[0070] The first heater head 7 and the curved pipe portion 14 of the second heat transfer piping group 6 are arranged adjacent to each other in the vertical direction. Similarly, the curved pipe portion 14 of the first heat transfer piping group 5 and the second heater head 8 are arranged adjacent to each other i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com