Bent type five-core flat cable

A flat cable and curved technology, applied in the field of curved five-core flat cables, can solve the problems of uncompact structure and increase the cable length, and achieve the effect of saving filling materials and wrapping tape, reducing laying space and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with accompanying drawing:

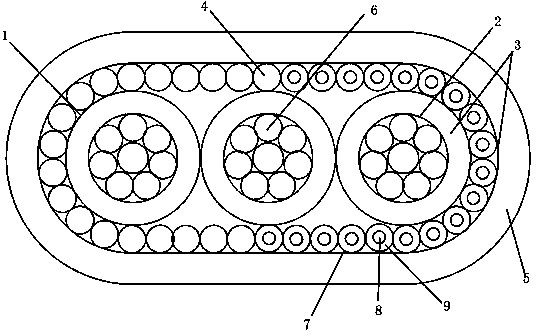

[0018] like figure 1 As shown, a curved five-core flat cable according to the present invention has a flat structure, three parallel phase cores 1 are arranged in the center of the cable, and a half-circle of ground wires are arranged side by side outside the phase core 1 The core conductor 4 and several neutral wire cores 7 in a half circle, the ground wire core conductor 4 and the neutral wire core 7 are wrapped with a wrapping tape 3 , and the wrapping tape is extruded and wrapped with a sheath 5 . The phase line core is composed of a phase line conductor 2 and a wrapping tape 3 wrapped around the phase line conductor 2; the neutral line core 7 is composed of a neutral conductor 8 and an outer insulation layer extruded on the neutral conductor 8 9; the phase line conductor 2 is formed by twisting several monofilaments 6; the ground line core conductor 4 and the neutral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com