Inductor and manufacturing method

A manufacturing method and inductor technology, applied in the field of inductors, can solve the problems of increasing the number of parts, complicating the manufacturing process, and increasing production costs, and achieve the effect of ensuring electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

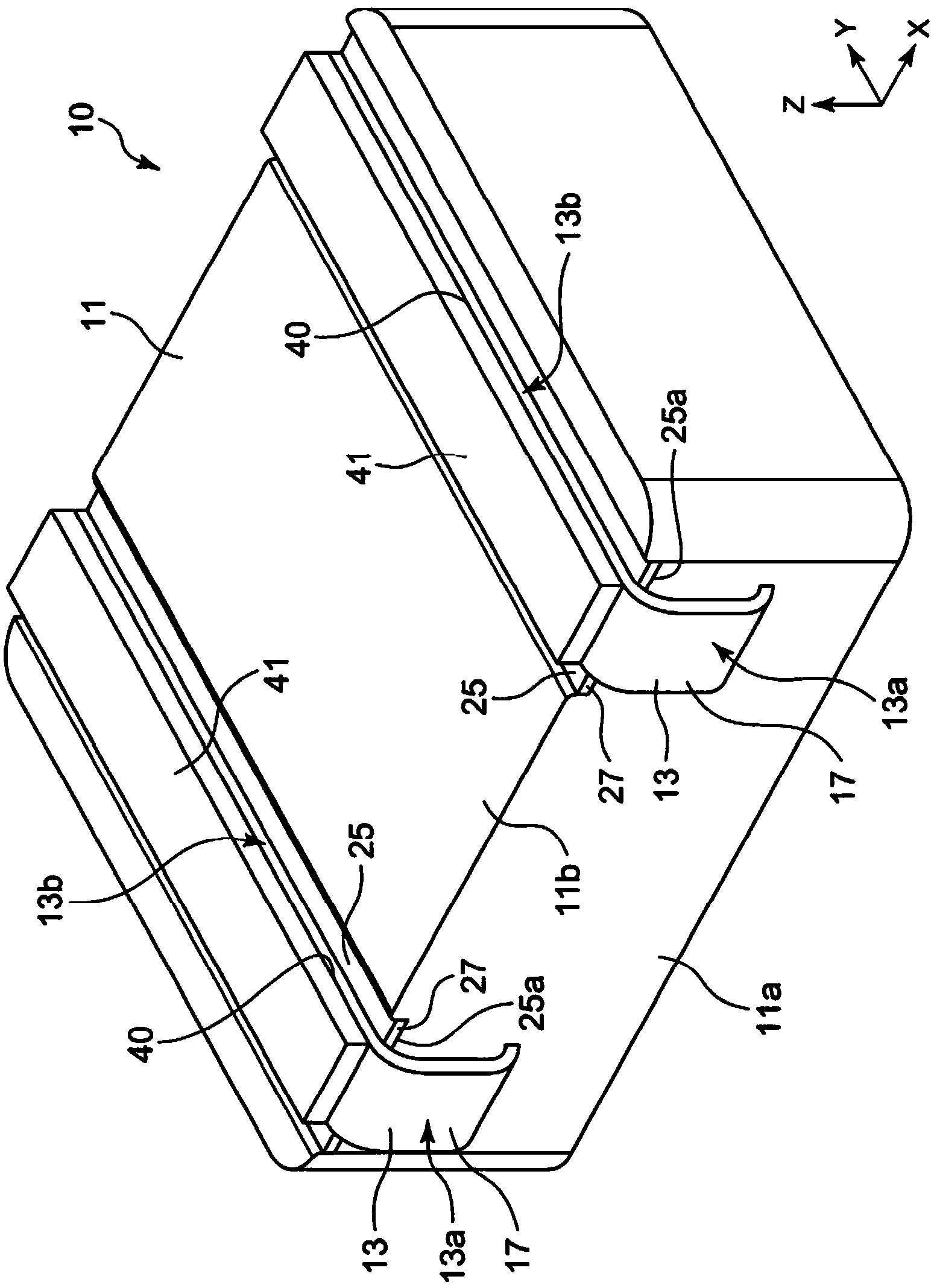

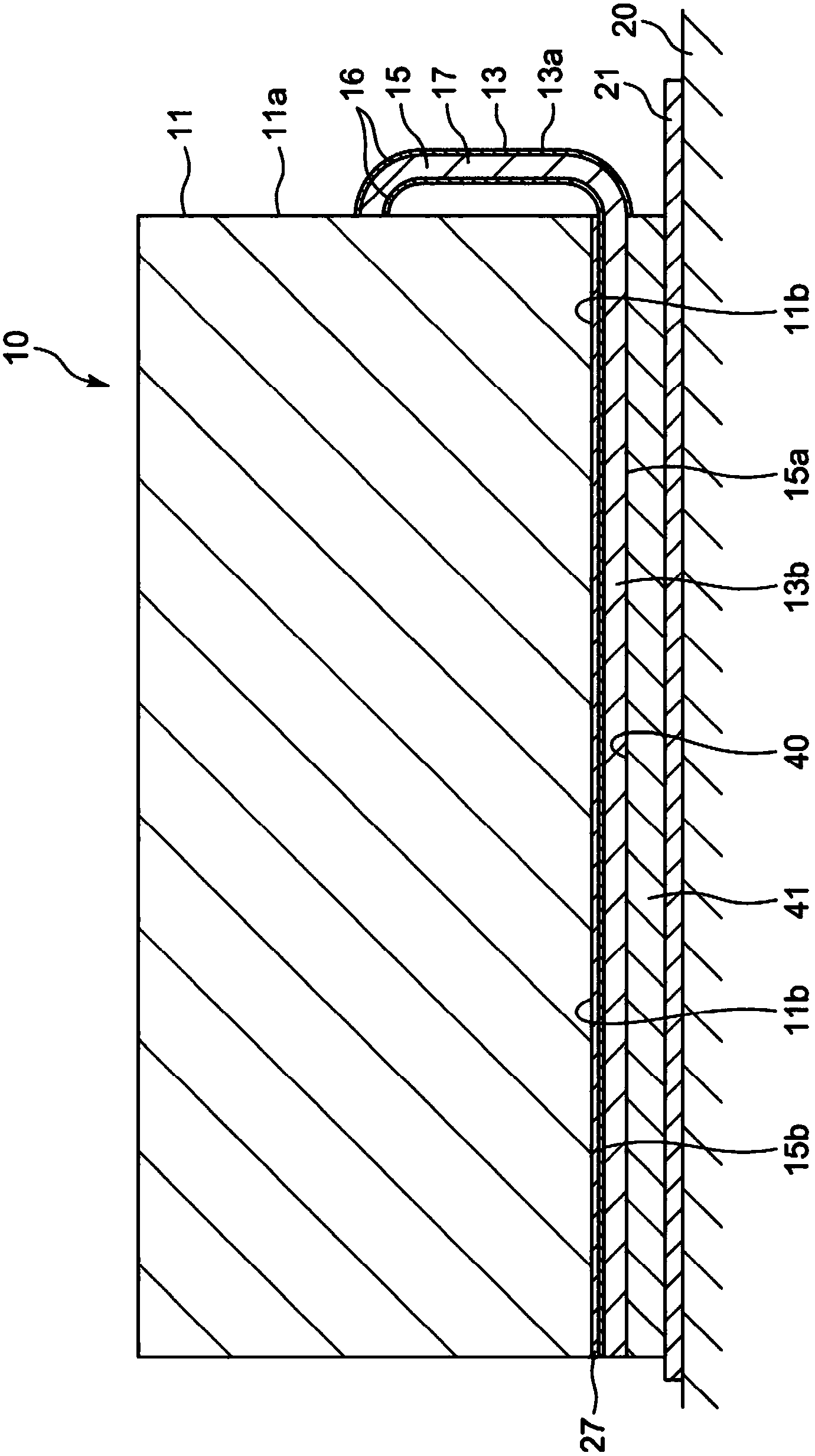

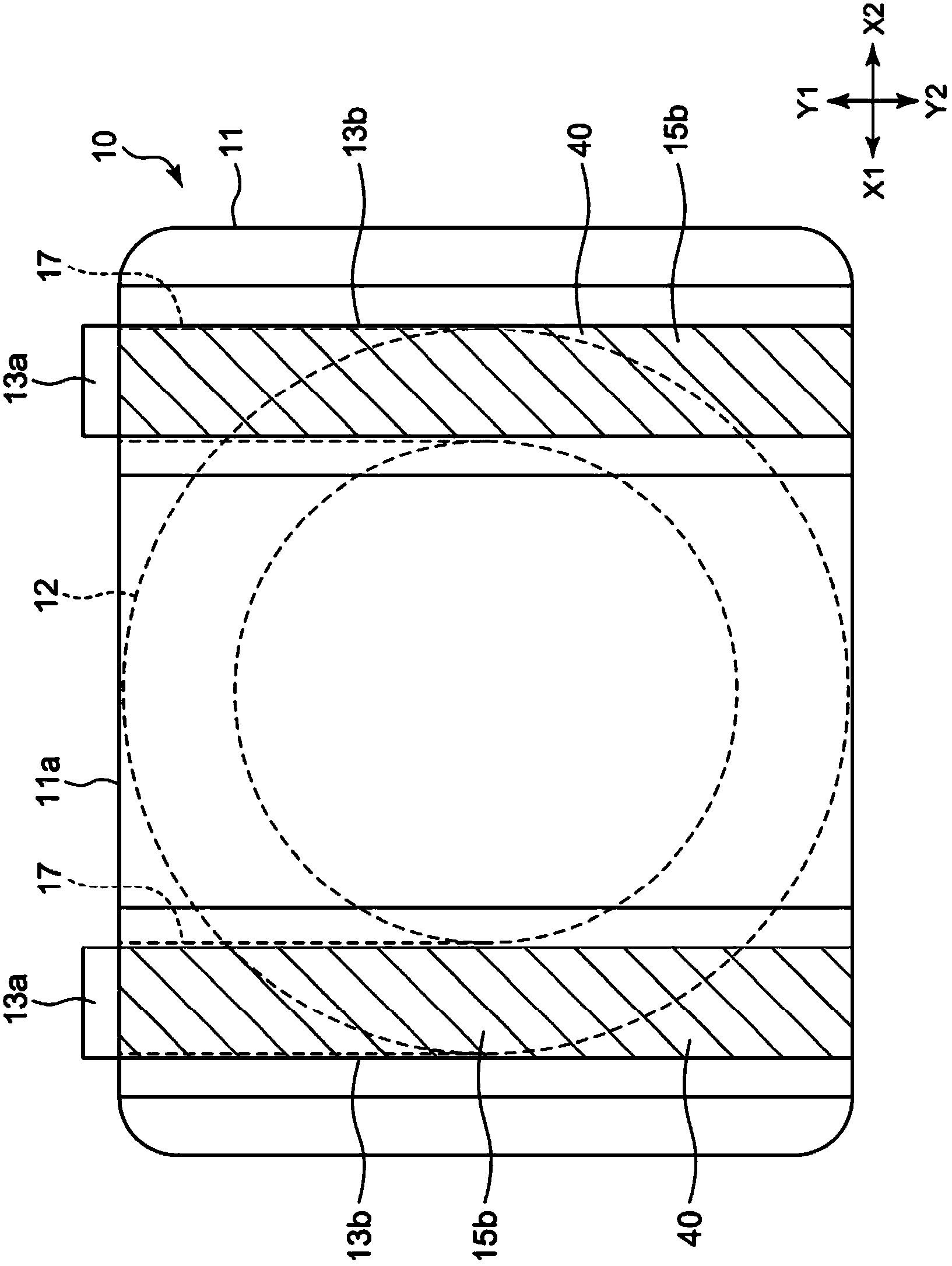

[0065] figure 1 is a perspective view of the inductor in the first embodiment, figure 2 will be figure 1 A longitudinal sectional view of the state where the inductor is mounted on the substrate shown, image 3 is a rear view (bottom view) of the inductor in this embodiment, Figure 4 (a) shows an enlarged cross-sectional view of a terminal located on a side surface of a magnetic core, Figure 4 (b) shows an enlarged sectional view of a terminal located on the lower surface of the magnetic core, Figure 4 (c), Figure 4 (d) means Figure 4 Modified example of (b). It should be noted that, in figure 2 In the sectional view of , the partially exposed cross-section of the original coil 12 is omitted.

[0066] Such as figure 1 , figure 2 , image 3 As shown, an inductor 10 has a magnetic core 11 , a coil 12 and a plurality of terminals 13 , 13 .

[0067] The magnetic core 11 is obtained by compression-molding a plurality of Fe-based amorphous alloy (Fe-based metalli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap