Command and Signal Devices

A signal device and command technology, applied in substation/switch layout details, electrical components, electric switches, etc., can solve the problems of unfriendly installation and complicated assembly, shorten the installation time, simplify the assembly steps, and ensure the sealing function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

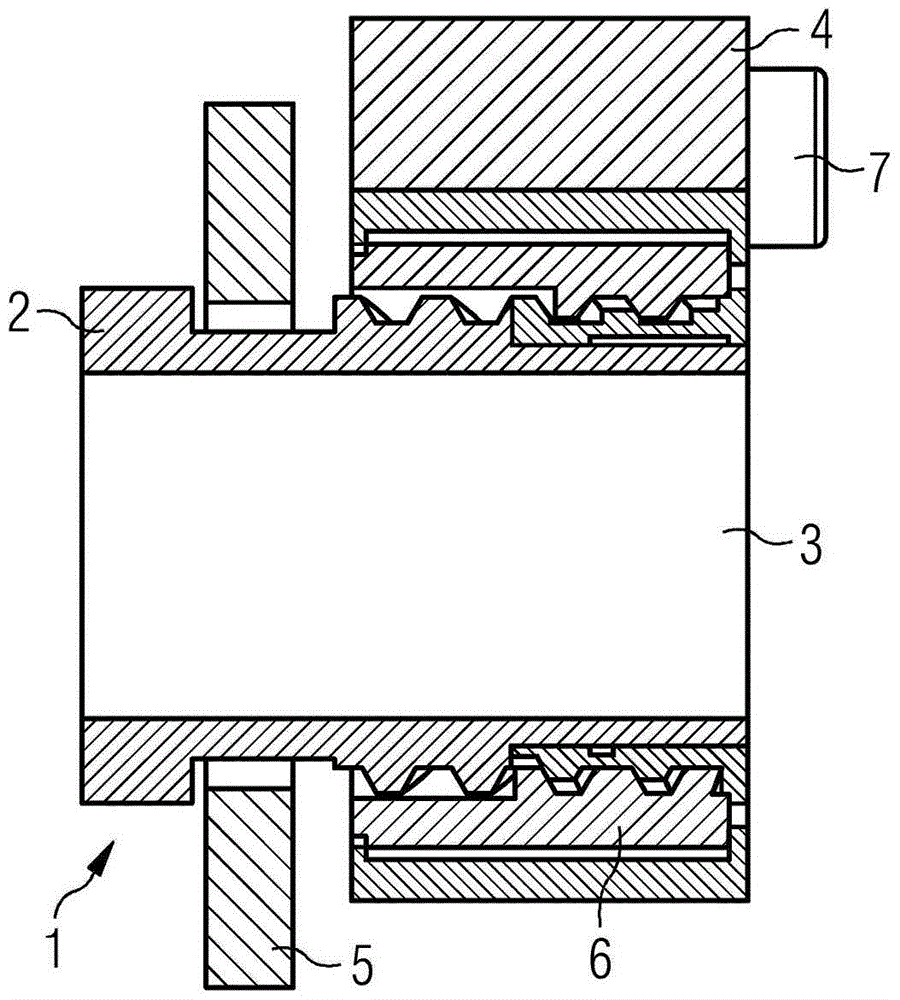

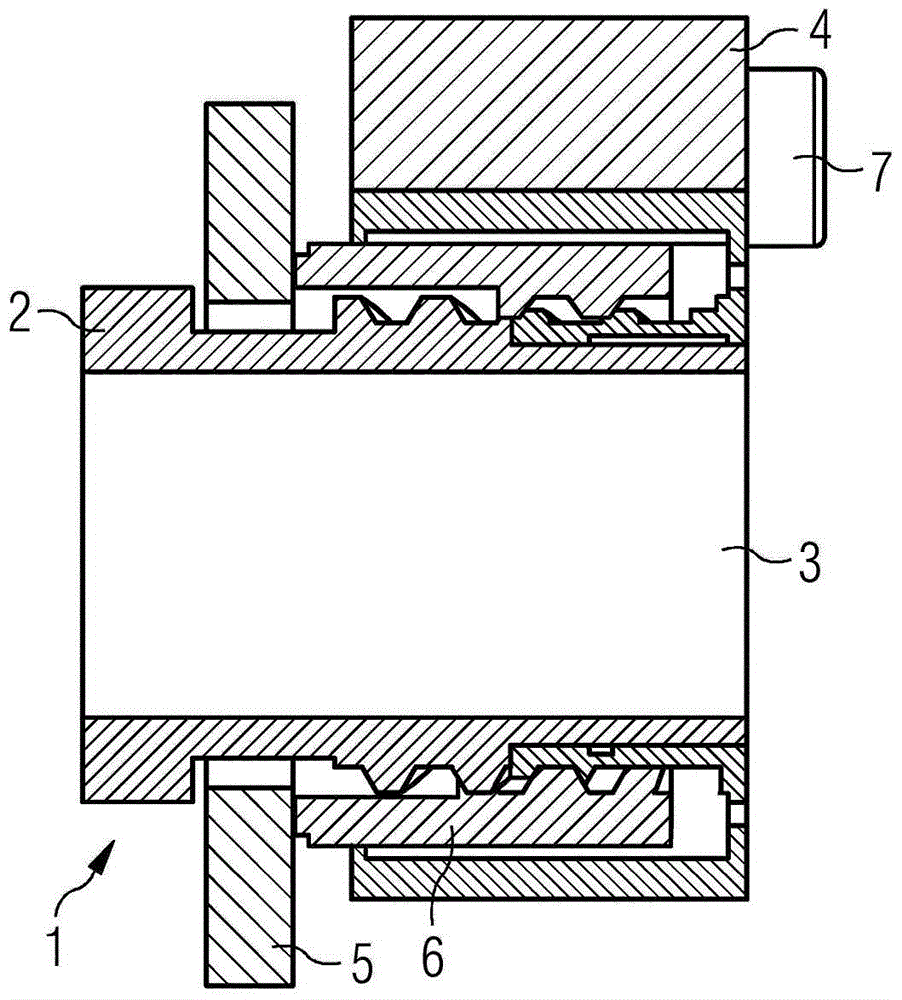

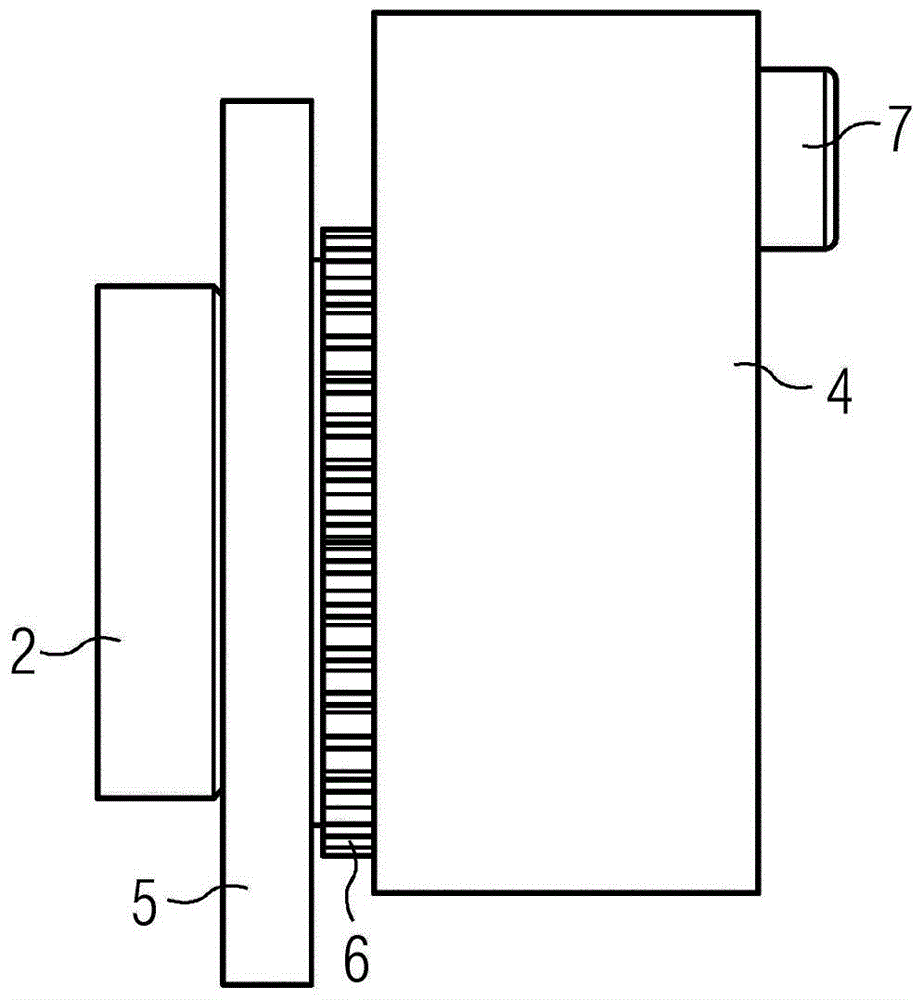

[0046] The command and signaling device according to the invention has an operating part 1 comprising a manipulator 2 with a cylindrical base body 3 , wherein the manipulator 2 preferably has a larger diameter than the cylindrical base body 3 . The command and signaling device also has a holding device 4 into which the operating element 1 is inserted. A switchboard 5 is arranged between the manipulator 2 of the operating element 1 and the holding device 4 . A threaded gear 6 driven by a pinion 7 is positioned in the holding device 4 . The cylindrical base body 3 of the operating element 1 is positioned in a threaded toothed wheel 6 . The pre-fixing of the actuating part 1 in the holding device 4 can take place in the holding device 4 by hooks or by positioning means. The final fixation is achieved by rotating the pinion 7 , which engages in the gear 6 and thus moves it in the direction of the switchboard 5 .

[0047] exist figure 2 Shown according to the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com