Motor shell with ring runner coiled from metal pipe and production process thereof

A technology for motor casings and metal pipes, applied in the manufacture of motor generators, casings/covers/supports, electrical components, etc., can solve the problems of waste of materials, time-consuming processing, liquid leakage, etc., to save material waste and production technology. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

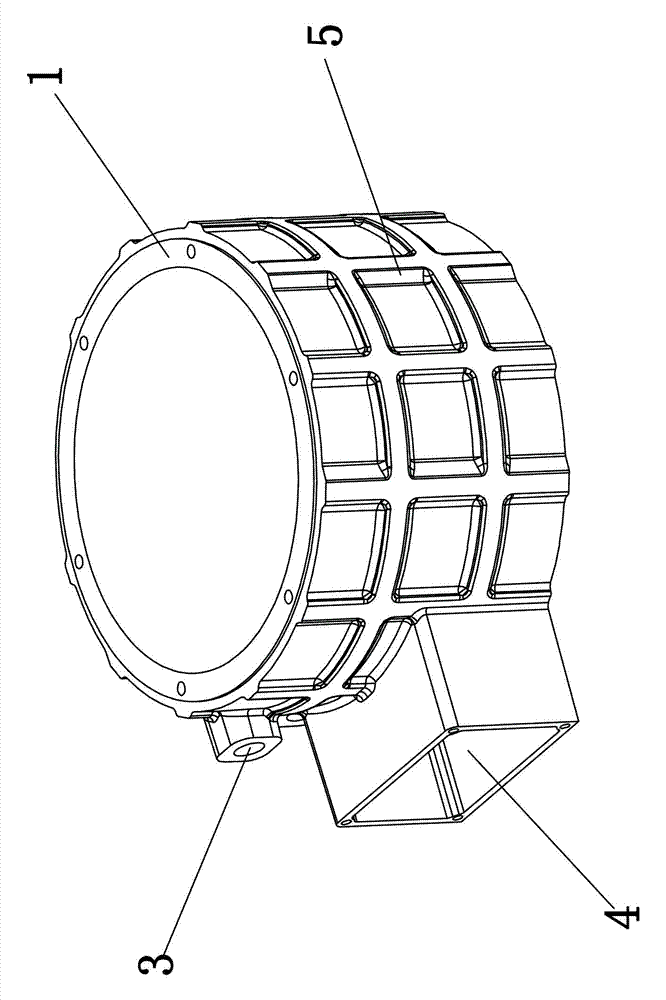

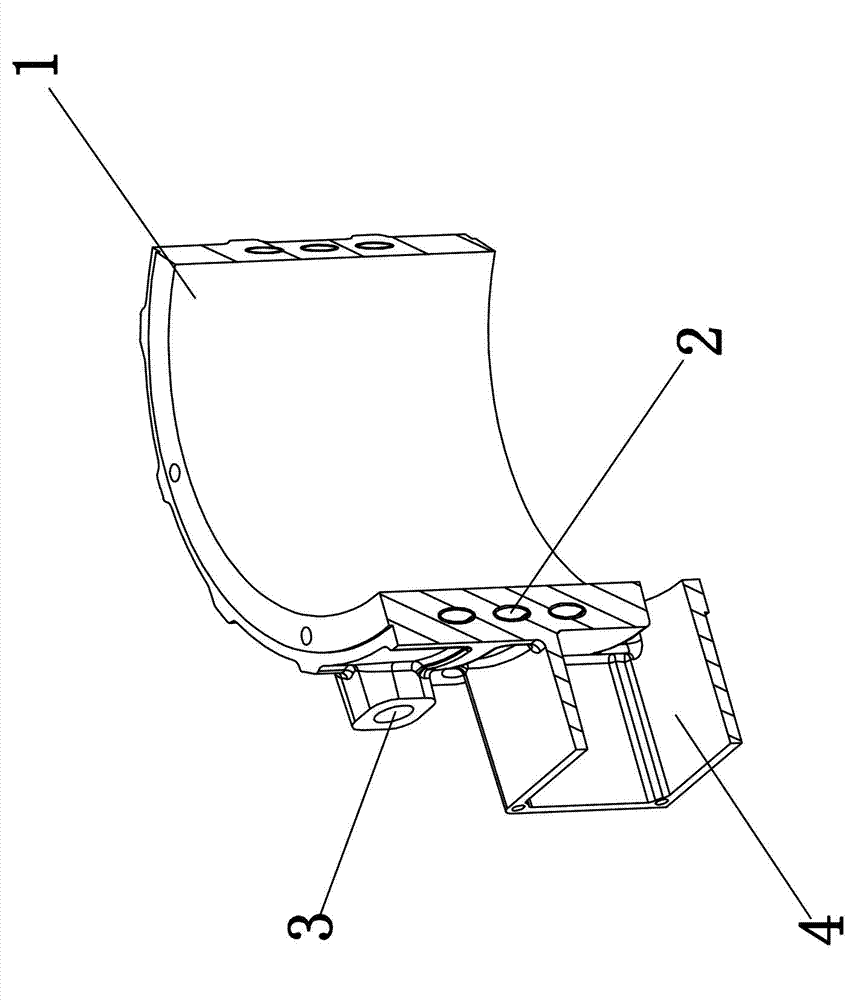

[0019] Such as figure 1 , figure 2 As shown, a motor casing with an annular flow channel wound by a metal pipe includes a motor casing shell 1, and the motor casing casing 1 is circular, and is provided with a water outlet 3 and a water inlet 4; the motor casing shell Inside the body 1, there is a spiral circular flow channel 2 formed by winding a metal pipe. The flow channel 2 is provided with a water inlet end and a water outlet end. The water inlet end of the flow channel 2 is connected with the water inlet 4. The flow channel 2 The water outlet of the water outlet is connected with the water outlet 3; the outer wall of the motor housing shell 1 is provided with a square rib 5.

[0020] A production process of a motor casing with an annular flow channel wound by a metal pipe, comprising the following steps: a. winding a metal pipe to form a required flow channel 2; b. processing the casting mold of the motor casing shell 1; c Place the flow channel 2 formed in step a in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com