Like pole type inductor motor hiding salient pole

A homopolar and inductive technology, applied in the field of homopolar induction motors, can solve the problems of torque ripple, large cogging torque, increased wind and friction loss, etc., so as to reduce cogging torque and eliminate cogging convexity. Polar effect, low wind and friction loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

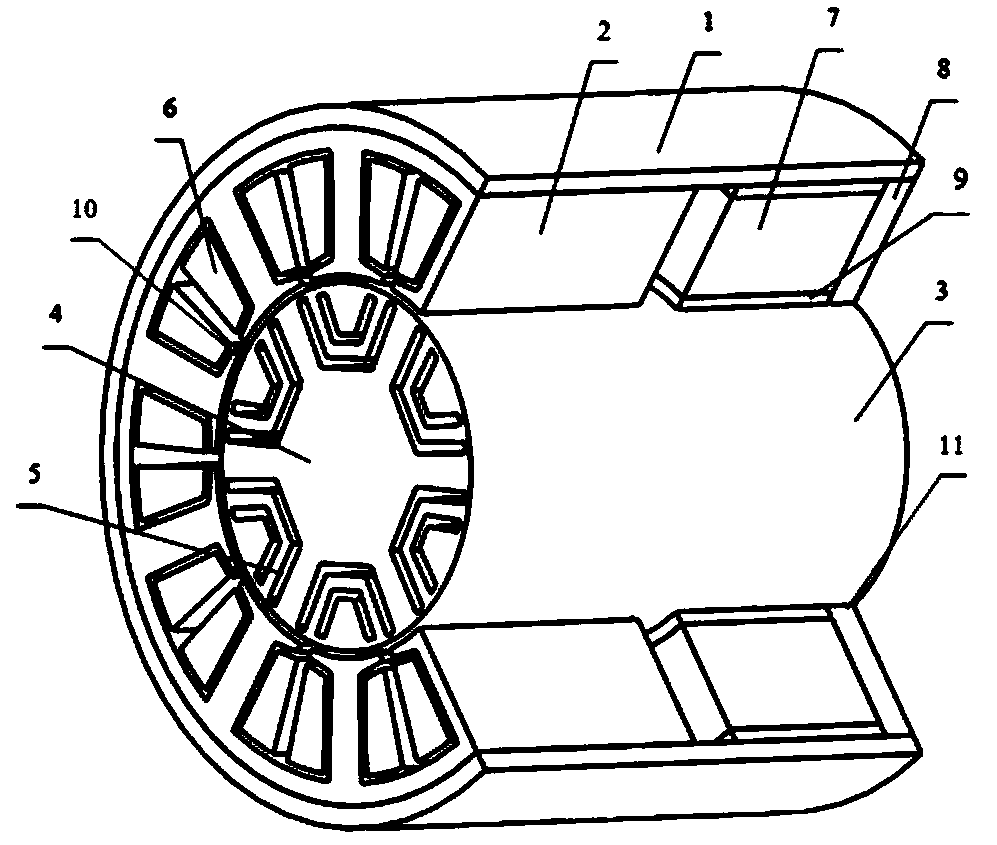

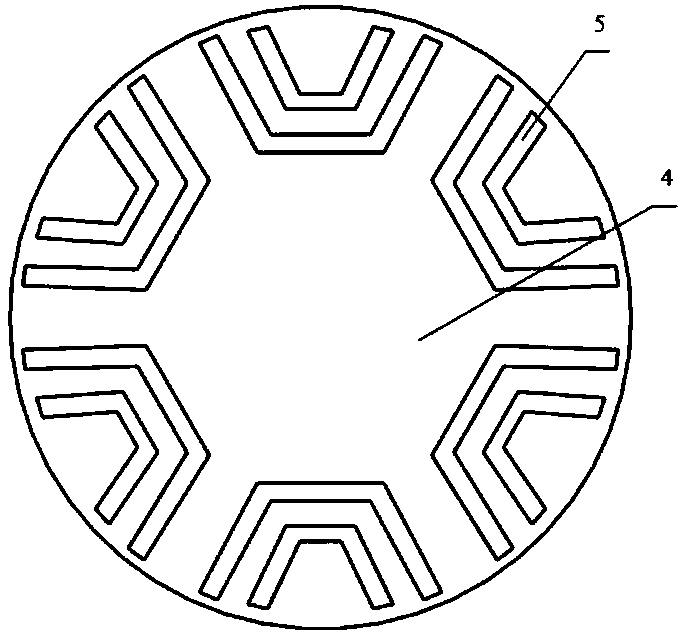

[0017] Embodiment 1: as figure 1 As shown, a homopolar induction motor with implied salient poles includes a stator part and a rotor part located inside the stator. Among them, the stator core of the motor adopts a laminated structure, which is formed by lamination of silicon steel sheets. The stator part includes a stator core 2 with slots, an armature winding 6, an annular excitation winding 7, an end cover 8, an excitation winding bracket 9 and Case 1. The armature winding 6 is a three-phase winding symmetrically wound on the stator core teeth, and the armature windings 6 belonging to the same phase are connected in series or in parallel to form a phase winding. The annular field winding 7 is arranged between the armature winding 6 and the end cover 8 , and the annular field winding 7 is fixedly connected to the casing 1 through the field winding bracket 9 . Among them, the stator core 2 is formed by stacking iron core punches with slots, and the casing 1 and the end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com