A position sensor for brushless DC motor

A brushed DC motor and sensor technology, applied in electromechanical devices, electrical components, etc., can solve the problems of large starting current fluctuation, increased volume and weight, long self-recovery time, etc., and achieve high reliability, light weight and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The advantages of the present invention will be further described below in conjunction with specific embodiments and drawings.

[0026] In the preferred embodiments disclosed below, the permanent magnet rotor pole pair number M is 4, and the stator phase number N is 3 as an example.

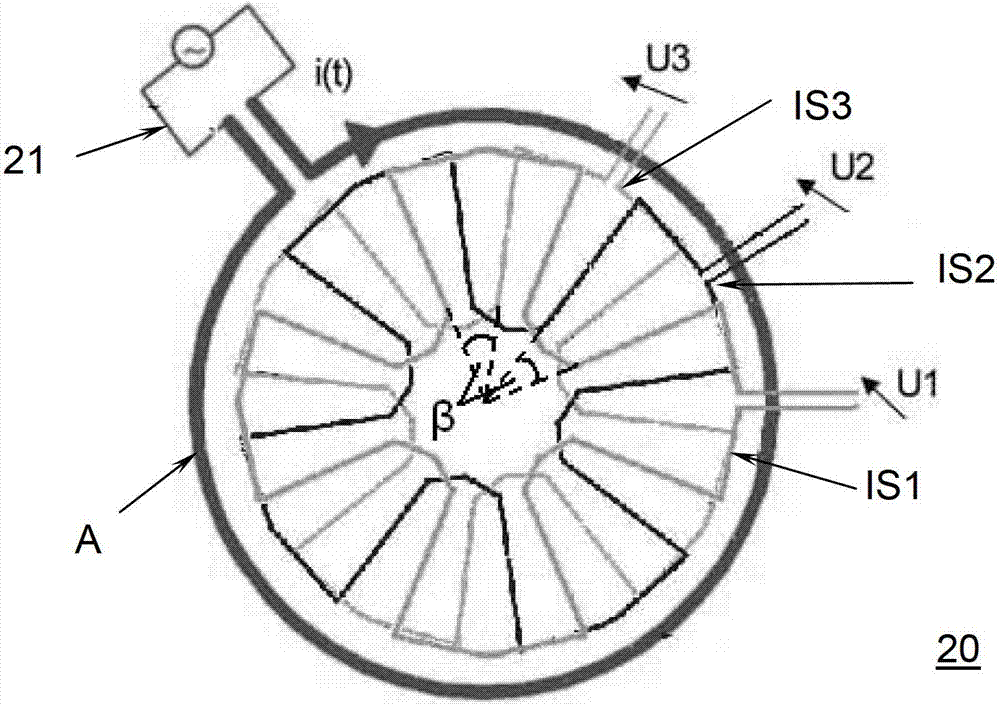

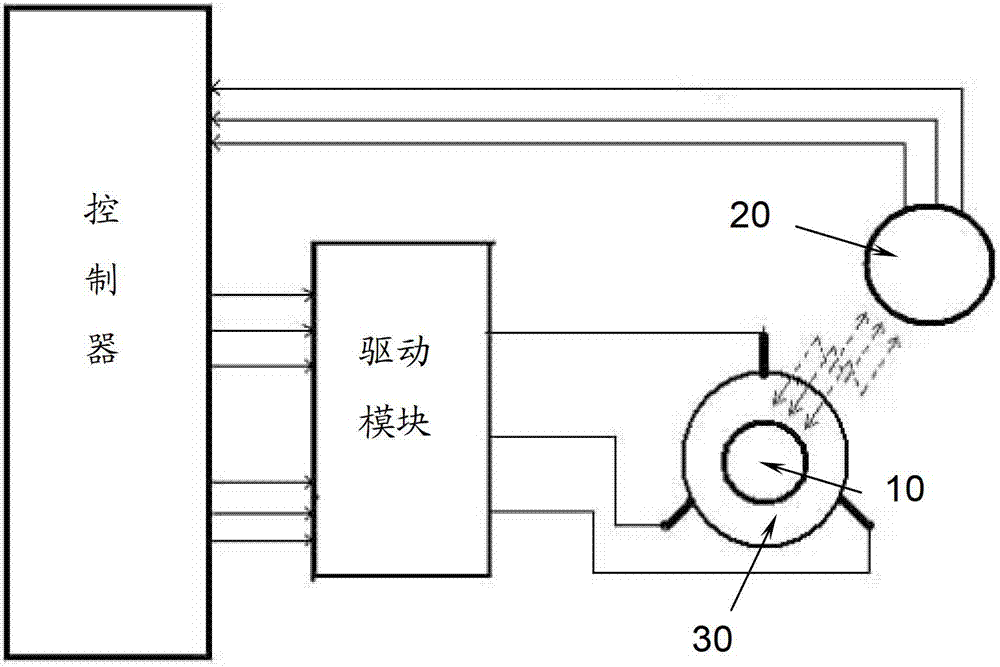

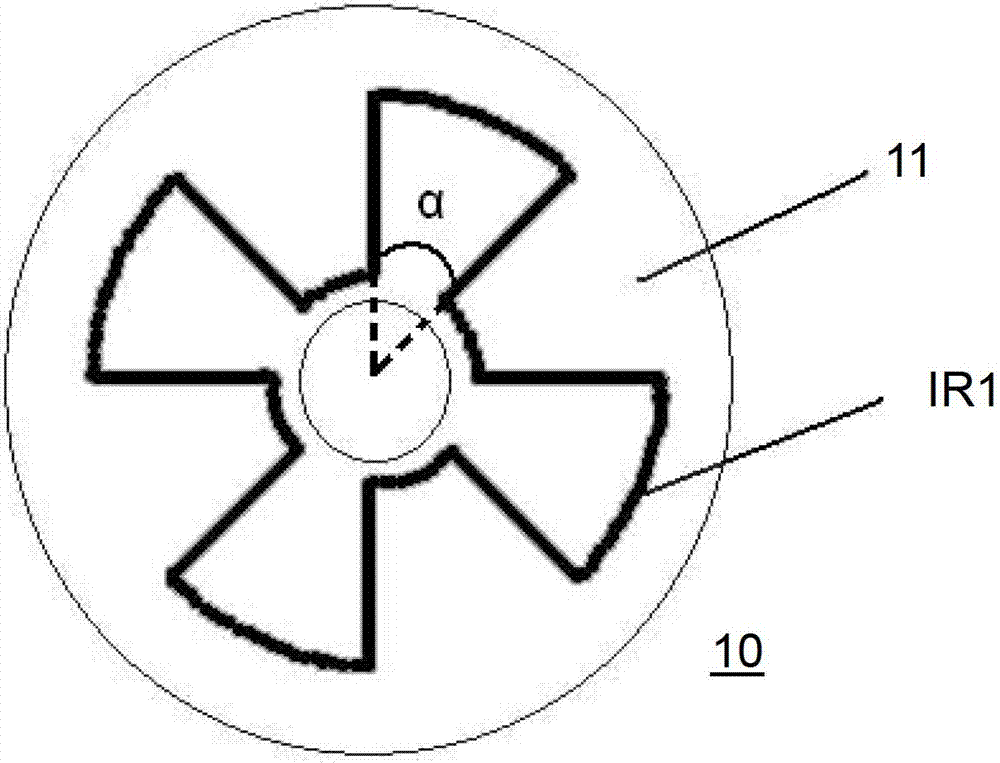

[0027] See figure 1 , figure 2 , Respectively show the rotor part 10 and the stator part 20 of the position sensor 100 provided by a preferred embodiment of the present invention.

[0028] The rotor part 10 is composed of a rotor printed circuit board 11 and a rotor induction coil IR1. The rotor printed circuit board 11 has a central hole 12 for fixed connection with the rotating shaft (not shown) of the brushless DC motor. The rotor induction coil IR1 is arranged around the central hole 12, and 4 protruding fan blades are evenly arranged in the circumferential direction. According to α=180 / N, the angle α of each protruding fan blade is 45 degrees, and the angle between two adjacent protruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com