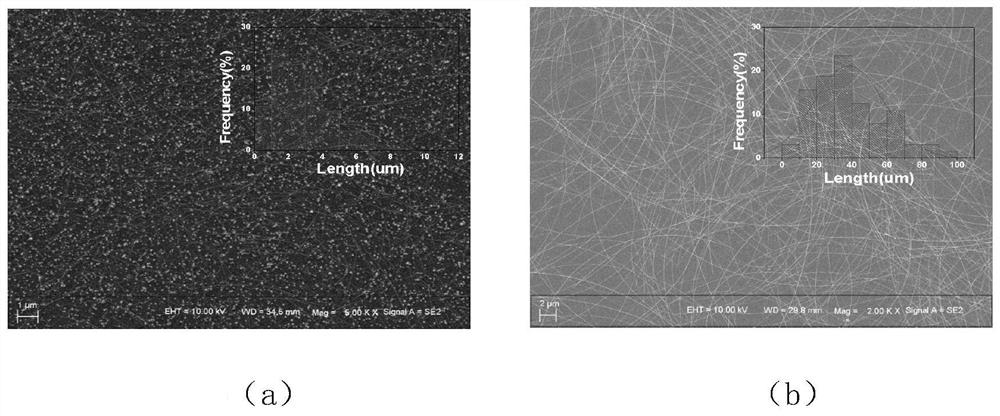

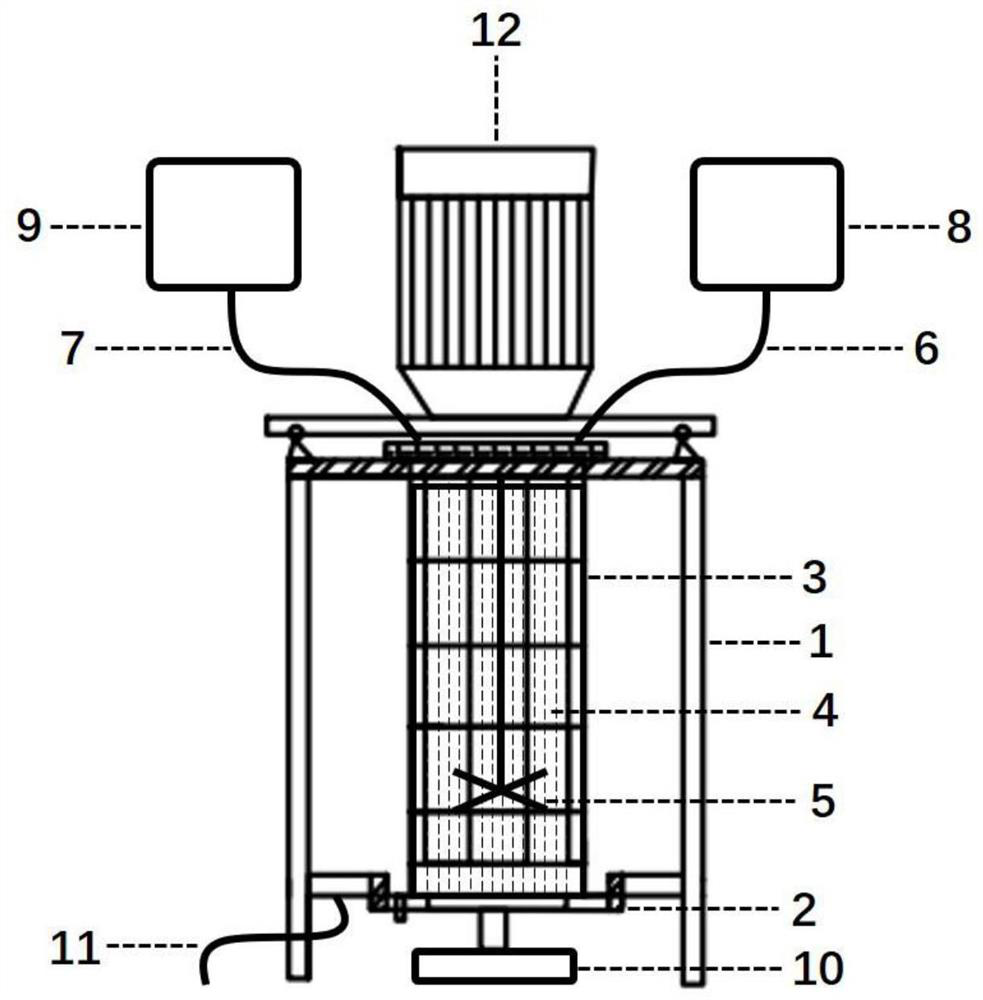

Method and special device for stirring induced centrifugal force-vertical filtration and purification of silver nanowire mother liquor

A silver nanowire, filtration and purification technology, applied in chemical instruments and methods, transportation and packaging, semi-permeable membrane separation, etc., can solve the problems of high impurity content, unstable quality, and high production cost of silver nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

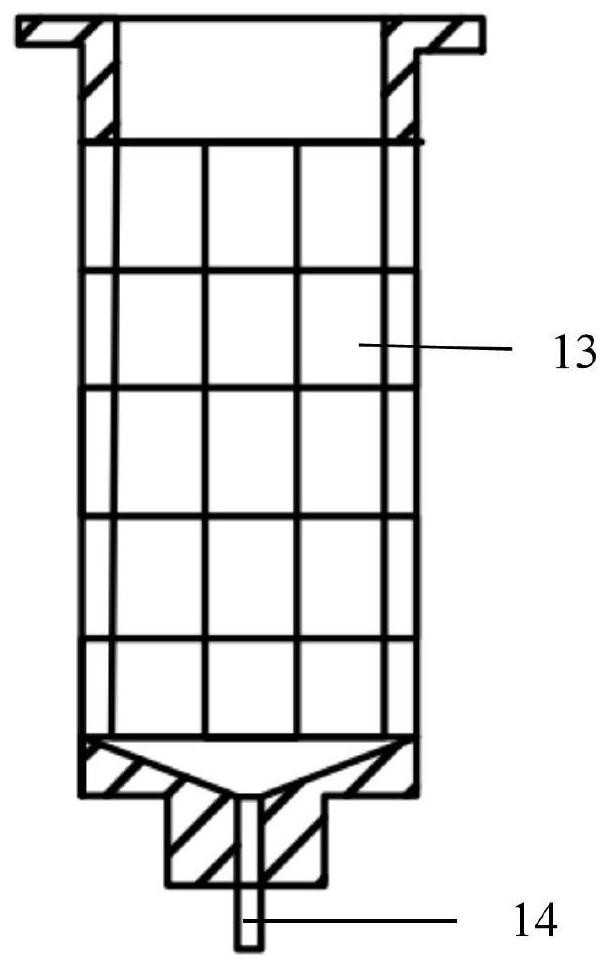

Method used

Image

Examples

Embodiment 1

[0043] (1) Take 2gAgNO 3 Add it to 40ml of ethylene glycol solution, and stir and dissolve it in a brown round bottom flask for 2 hours to make it completely dissolve.

[0044] (2) Add 2g of PVP to 160ml of ethylene glycol solution, heat the magnet and stir to make it completely dissolved, then add 16.32ml of NaCl solution (7.2mM), stir for 5min to make it dissolve, and cool to room temperature.

[0045] (3) Under magnetic stirring, the AgNO in step (1) 3 The solution is added to the mixed solution in step (2), and stirred for 5-10 minutes to make it evenly mixed.

[0046] (4) Add the mixed solution into a preheated blast oven at 110° C., heat and react for 12 hours, and after the reaction is completed, rapidly cool in a cold water bath to room temperature to obtain the silver nanowire mother liquor.

[0047] (5) Put the 5 micron pore size nylon filter membrane from the bottom of the vertical filter wall unit of the centrifugal stirring filter equipment, then seal the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com