Endoscope joint ring, endoscope bent part and corresponding endoscope device

A technology of endoscope and bending part, which is applied in the field of medical equipment, can solve the problems of high difficulty in processing, high difficulty in stamping, and reduction of effective available space, so as to achieve the effect of ensuring smooth traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

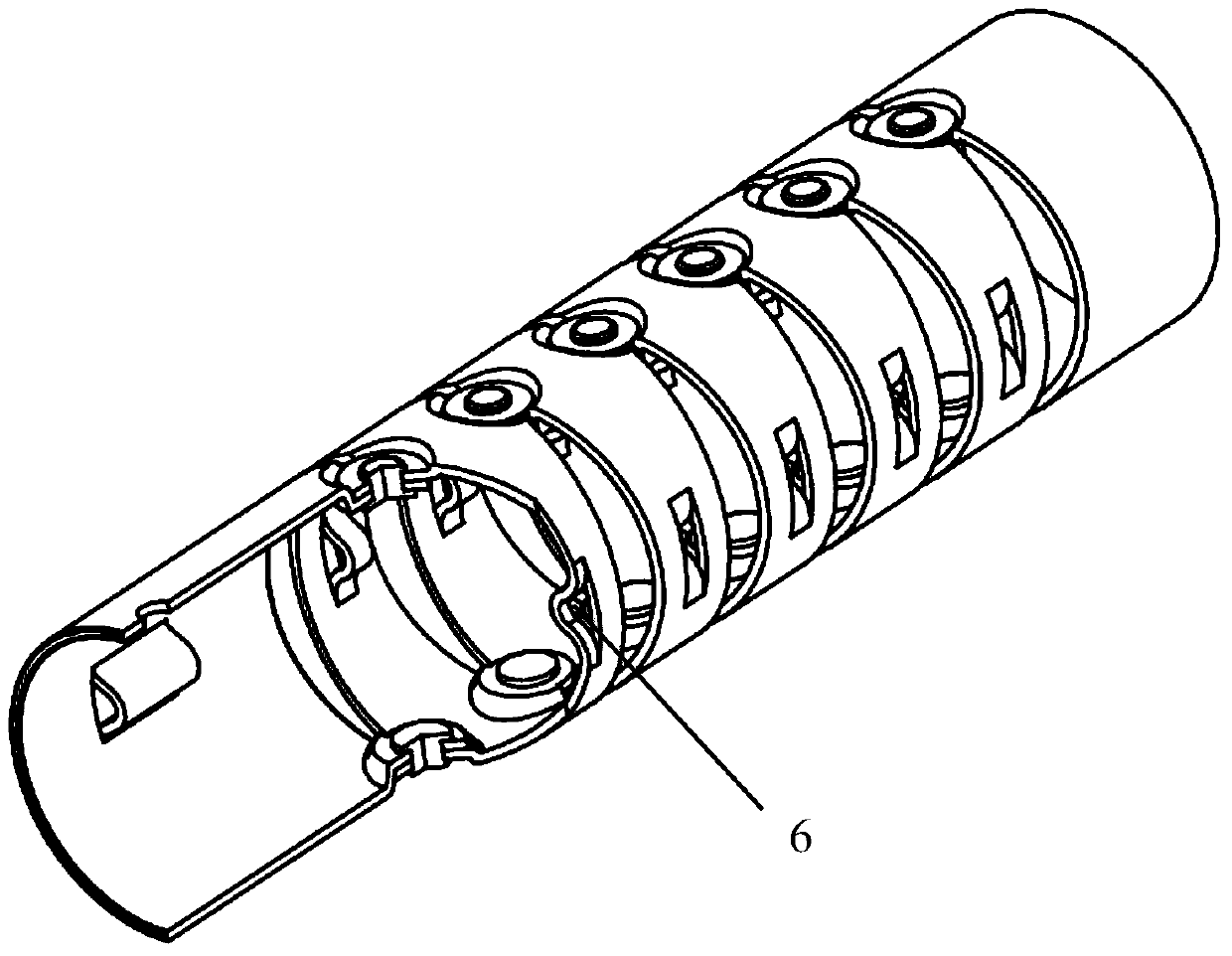

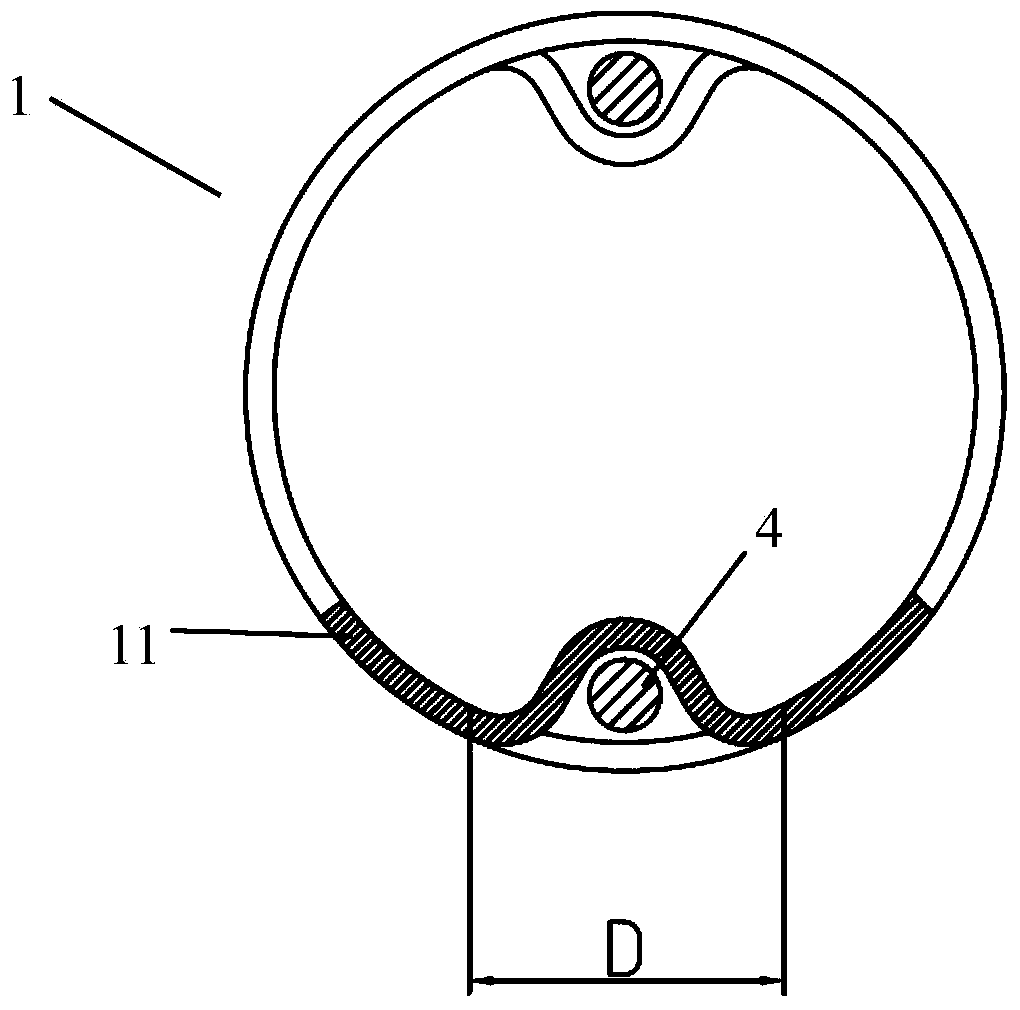

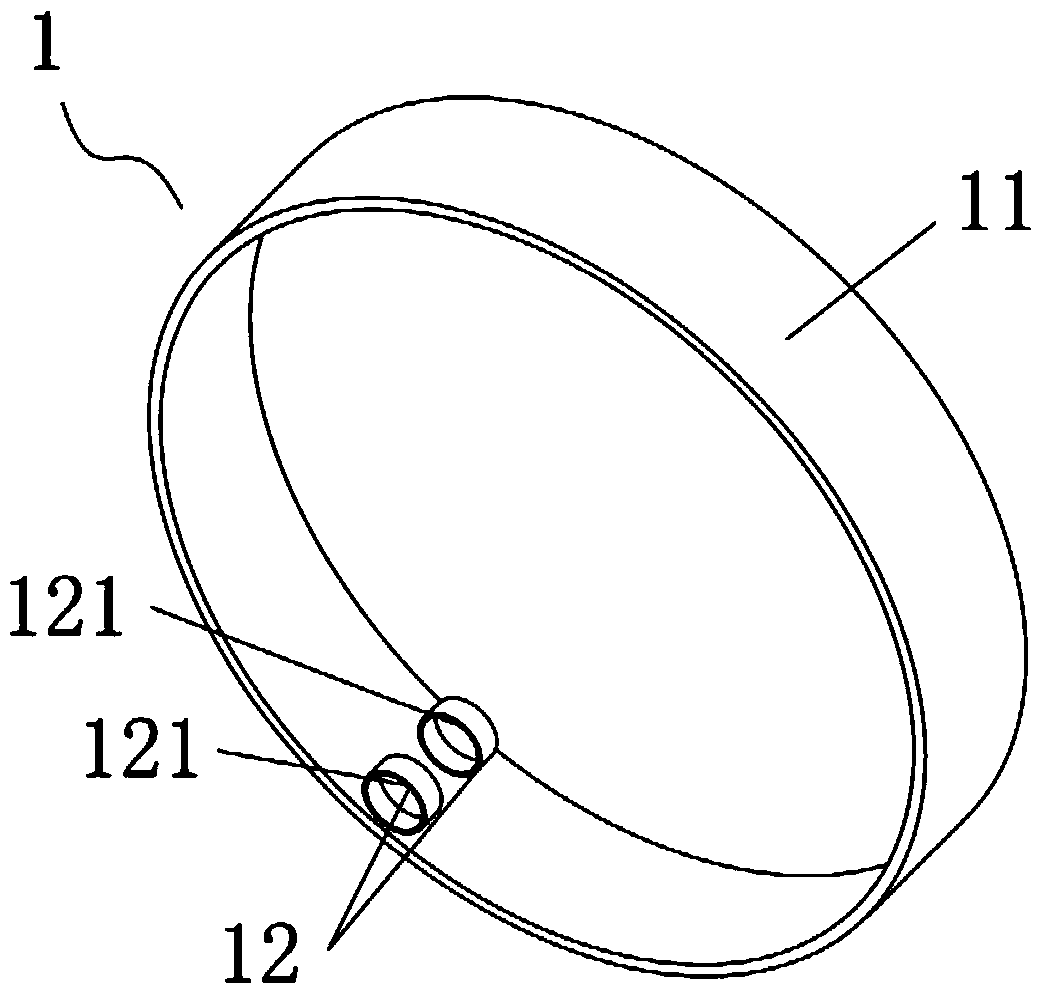

[0047] see Figure 3 to Figure 6 , the endoscope joint unit 1 includes a joint ring body 11 and a constraining locator 12. The constraining locator 12 is a component with a closed periphery and is independent of the joint ring body 11. Since the constraining locator 12 and the joint ring body 11 They are mutually independent components, so the material properties, size, wall thickness and shape of the constraining locator 12 are not affected by the joint ring body 11, and the selection flexibility is strong, not only convenient for production and processing, but also compatible with the constrained locating member 12. The endoscope operating part 4 is better matched to save the space inside the joint ring body 11. The constraint positioning part 12 has a through hole 3 for positioning and constraining the endoscope operating part 4. The restr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com