Spigot shaft type stirring mud scraper driving device

A technology of driving device and mud scraper, which is applied to the feeding/discharging device of the sedimentation tank, chemical instruments and methods, separation methods, etc., can solve the problems of difficulty, complex structure and large area, and achieve simple structure , the effect of simplifying the floor space and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

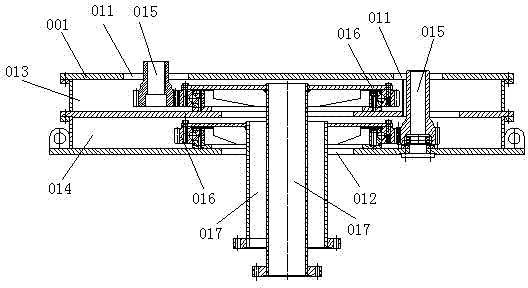

[0009] A driving device for a shaft-type stirring mud scraper, including a reducer case 001, two reducer output shaft connection holes 011 are opened on the upper cover of the reducer case 001, and one output hole is opened in the center of the bottom plate of the reducer case 001 012, the inner cavity of the reduction box 001 is divided into upper and lower chambers (013, 014), each chamber is provided with a transmission pinion 015 and a passive large gear 016 that mesh with each other, and the transmission of each chamber is small The end of the gear 015 corresponds to the reducer output shaft connection hole 011 on the upper cover of the reducer case 001; the center of the passive gear 016 in each layer of the chamber is coaxially connected to the transmission shaft 017, and each transmission shaft 017 passes through the reduction gear The output hole 012 in the center of the bottom plate of the chassis 001 is set to be nested with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com