A composite tower methanation reactor

A methanation reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, gas fuels, etc., can solve problems such as deepening the reaction balance, and achieve the goal of increasing the balance depth, reducing settings, and reducing pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

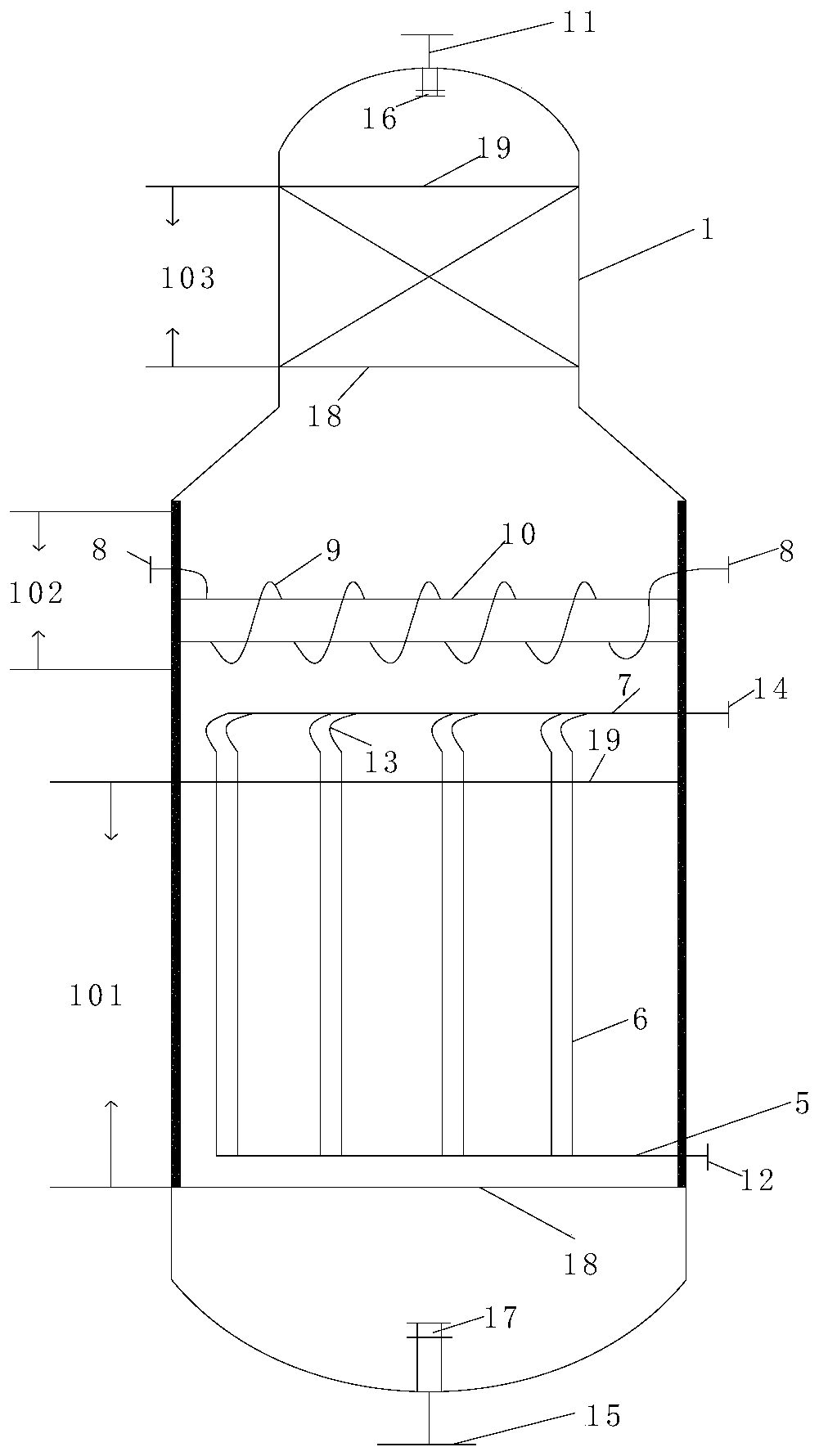

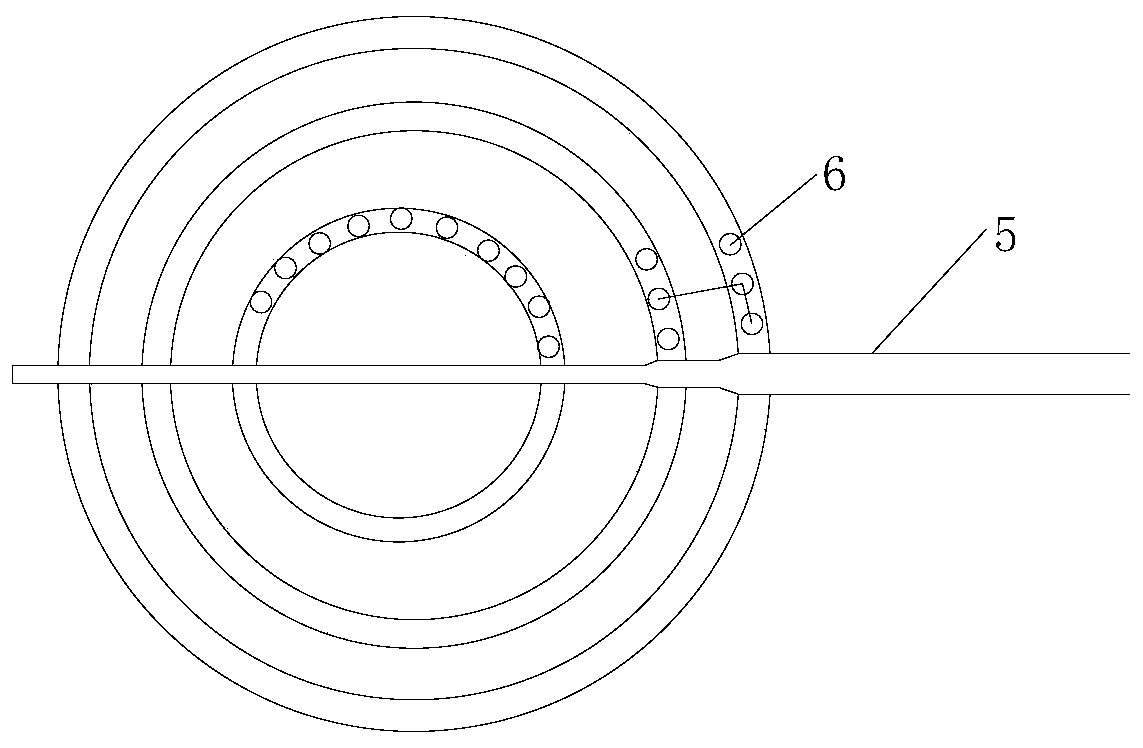

[0042] In one example of the present invention, adopt as figure 1The shown compound tower methanation reactor carries out the methanation reaction process, and the specific process is: the feed gas enters the different diameter tower pressure housing 1 of the composite tower methanation reactor from the feed gas inlet pipe 15, and The gas distributor 17 is evenly distributed on the cross-section of the reactor, and then enters the lower isothermal reaction zone 101; the support grid 18 provided below the lower isothermal reaction zone 101 is used to support the catalyst bed above, and on the support grid 18 is a A layer of 200mm thick heat-resistant ceramic balls, above the ceramic balls is an isothermal methanation reaction catalyst. The heating medium adopts the way of generating 4.0MPag grade steam from the boiler feed water. The boiler feed water enters the reactor through the heating medium inlet 12 through the heating medium distribution large ring pipe 5, and the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com