Supporting rod device for stack handling gripper

A technology of handling hands and support rods, which is used in transportation and packaging, manipulators, stacking of objects, etc., can solve the problems of unreliable positioning, easy scratching of cartons, poor rigidity, etc., and achieves light weight, simplified structure and land occupation. Good area and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The utility model will be further described in detail below in conjunction with the accompanying drawings and embodiments.

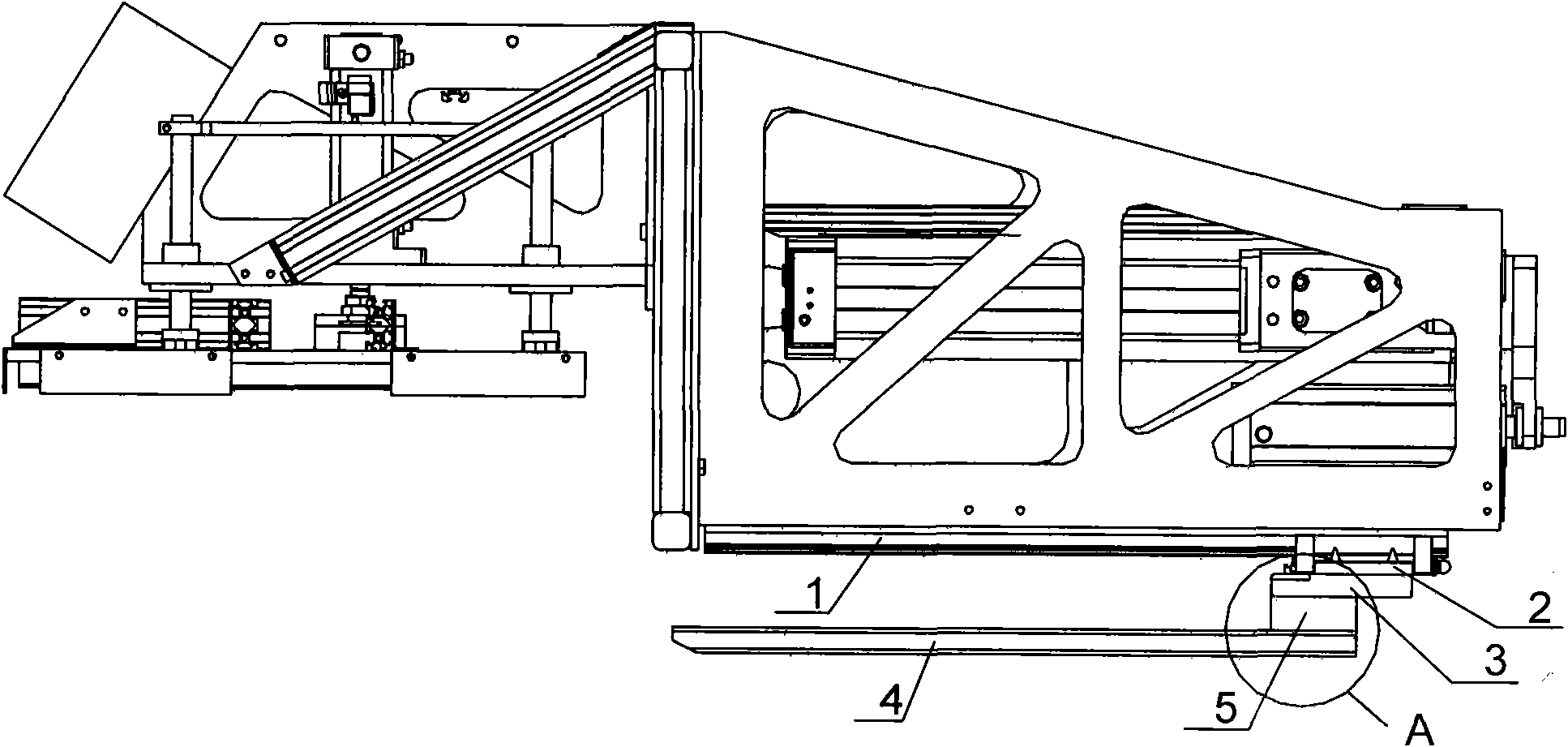

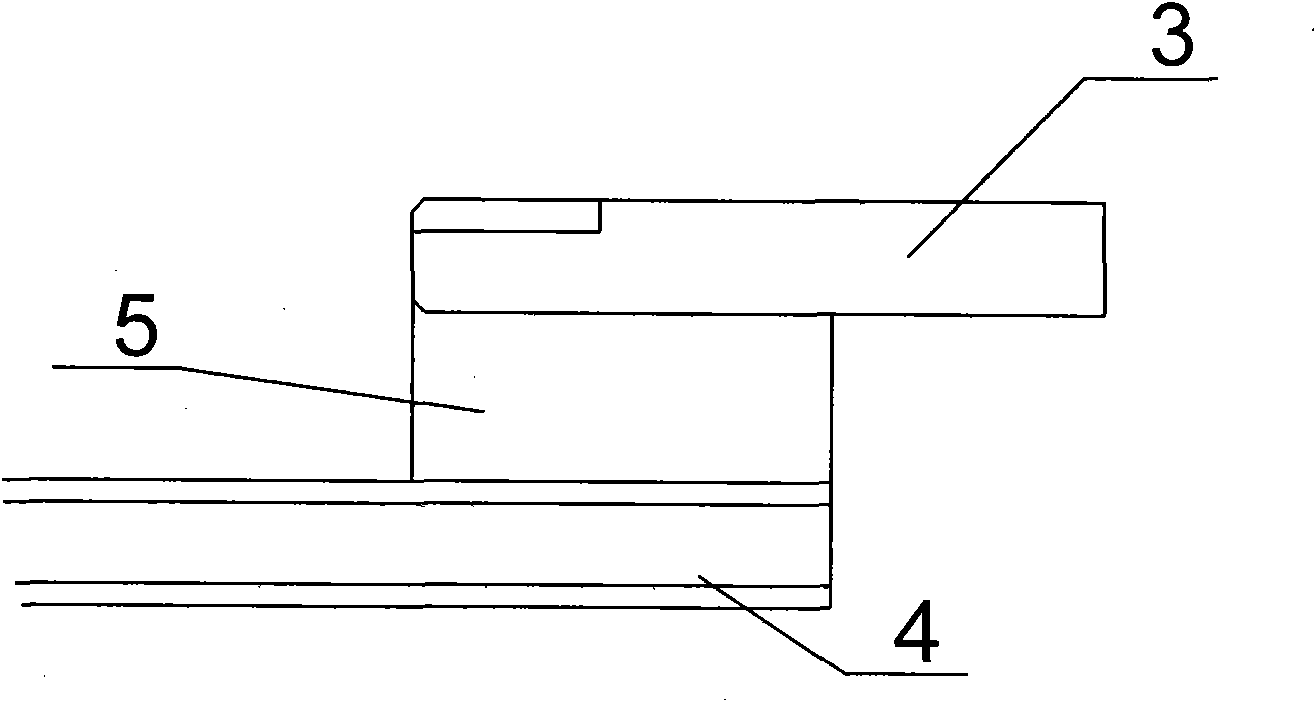

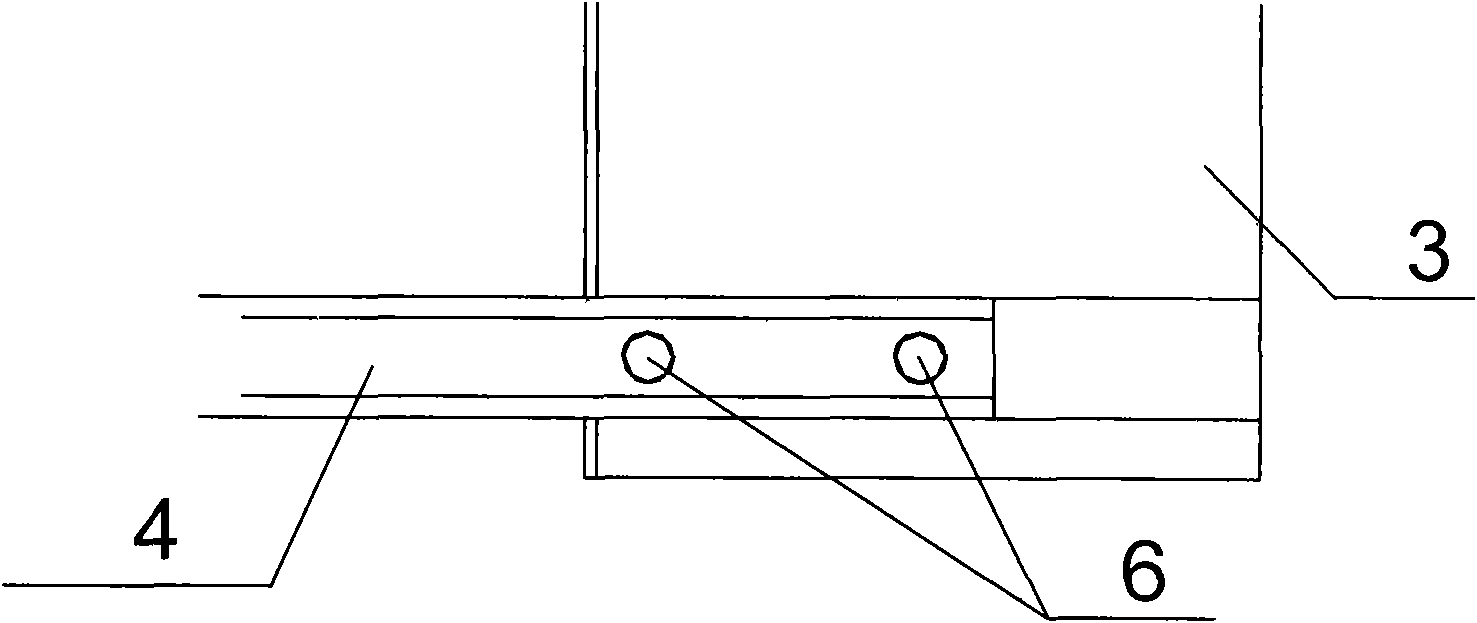

[0015] see figure 1 , with reference to Figure 2 to Figure 4 , a support rod device used for palletizing and handling claws of the present invention, the device is installed on the linear guide rail 1 of the palletizing and handling claw through a slider 2 and can move forward and backward along the linear guide rail 1, and the support rod device includes A plurality of support rods 4 and a support rod guide plate 3, the support rod 4 is a hollow rectangular tube, which has the characteristics of good rigidity and light weight.

[0016] A positioning flat key 5 is provided between the positioning end of the supporting rod 4 and the supporting rod guide plate 5, and several grooves having the same width as the positioning flat key 5 are arranged on the lower plane of the supporting rod guiding plate 5. The rod 4 passes through the positioning fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com