A welding device and method for brazing material, core tube and brazing material

A technology of welding device and welding method, which is applied in the direction of welding equipment, welding medium, auxiliary equipment, etc., can solve the problems that the brazing material cannot be laid neatly, the brazing material is easy to shake, and the labor cost is increased, so as to improve the brazing quality and overall Improve connection strength, save raw materials, and improve welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

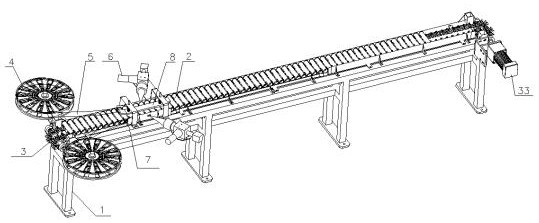

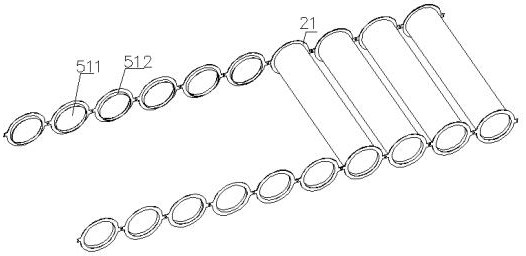

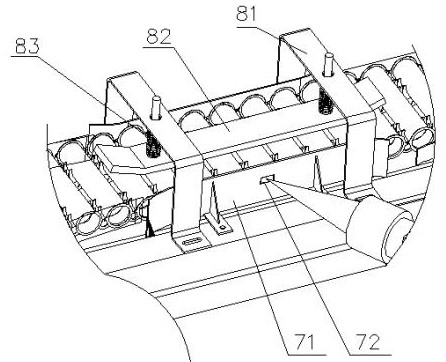

[0047] Such as figure 1 and figure 2 Shown: a welding device for a core tube and solder, including a frame 1, on which is provided a chain conveying mechanism 3 for conveying the core tube 2, one side of the chain conveying mechanism 3 is connected to a chain drive motor 33. Both sides of the entrance of the chain conveying mechanism 3 are provided with material boxes 4 respectively, and brazing material 5 is wound on the material boxes 4 . The core tube is arranged laterally on each sprocket 31 of the chain conveying mechanism, and the sprocket is provided with a groove 32 for accommodating the core tube. Lasers 6 are arranged on both sides of the conveying line of the chain conveying mechanism, and the lasers 6 on both sides face the two ends of the core tube 1, so that when the brazing material 5 is laid on the ends of the core tube 1, laser welding is carried out by the laser 6, Solder is integrally connected with each core tube. There are also guide mechanisms 7 on bo...

Embodiment 2

[0066] The difference from Embodiment 1 is that no pressing mechanism is provided at the position of the laser, and only the core tube is guided by the first guide plate.

[0067] Other structures are with embodiment 1.

Embodiment 3

[0069] The difference from Embodiment 1 is that the guide mechanism includes a first guide plate and a second guide plate, the first guide plate is arranged along the end of the core tube, and the second guide plate is connected with the first guide plate, and the brazing material flows from the first guide plate to the first guide plate. Pass through the gap between the guide plate and the second guide plate. Wherein the length of the first guide plate is greater than the length of the second guide plate, after the solder passes through the gap, it moves between the first guide plate and the end of the core tube, and the distance between the first guide plate and the end of the core tube It just makes the hole wall of the brazing filler metal insert into the core tube, so as to realize the tightness between the brazing filler metal and the core tube. In addition, the first guide plate is also used to guide and align each core tube so as to facilitate laser welding. Preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com