Powder cake break-up device of high-pressure paired-roller extrusion mill

A technology of roller extrusion and dispersing, which is applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of short service life, wear of dispersing devices, insufficient dispersing, etc., and achieve improved dispersing Dissipation efficiency, prolong service life, reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be described below in conjunction with specific embodiments.

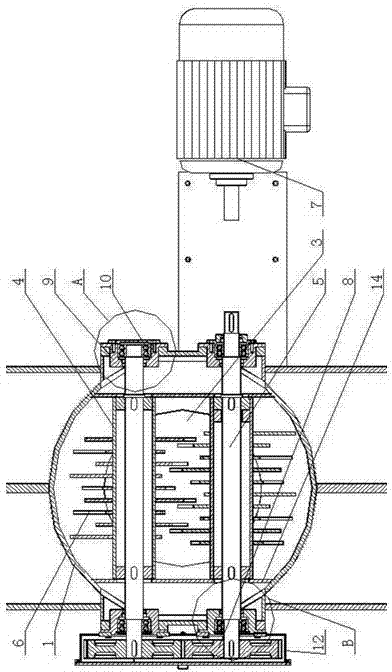

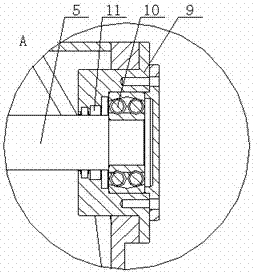

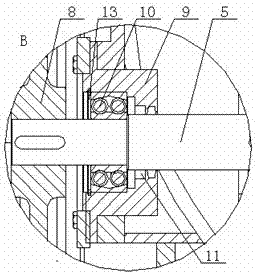

[0022] Such as Figure 1 to Figure 4 As shown, it is a structural schematic diagram of the powder cake breaking device of the high-pressure double-roll extrusion mill according to the present invention. The powder cake breaking device of the high-pressure double-roll extrusion mill of the present invention includes: a breaking cylinder 1 provided with an upper mouth 2 and a lower mouth 3, and the powder cake enters the breaking cylinder from the upper mouth 2 1. After breaking up in the breaking cylinder 1, it is discharged from the lower mouth 3 under the action of gravity; the breaking wheel 4 is arranged in the breaking cylinder 1, and the breaking wheel 4 is set through the support shaft 5 On the broken cylinder 1; the broken wheel 4 is made up of a plurality of coaxial broken blades 6, the plane of the broken blades 6 is perpendicular to the horizontal plane; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com