Large chemical equipment assembled by plate-shaped modules with anticorrosion liners and manufacturing method of chemical equipment

A technology of anti-corrosion lining and chemical equipment, which is applied in the field of large-scale chemical equipment assembled with plate-shaped modules and in the field of manufacturing. It can solve the problems of hidden dangers in service life, high difficulty, and low strength of PTFE welds, so as to ensure quality and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

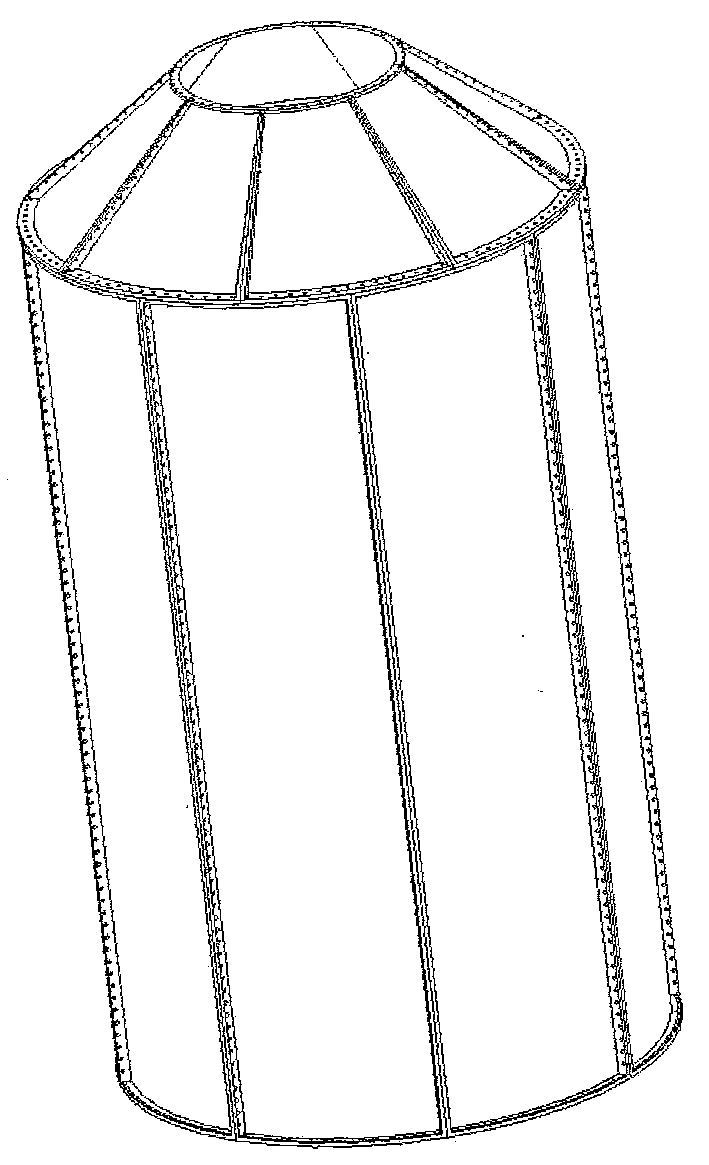

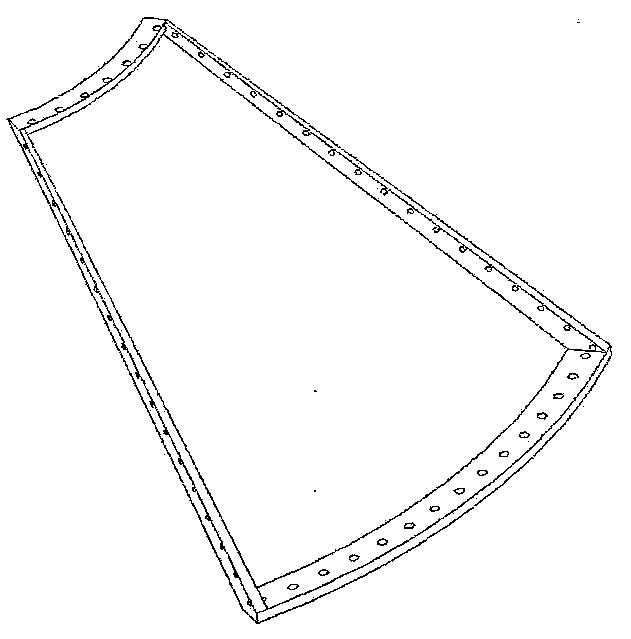

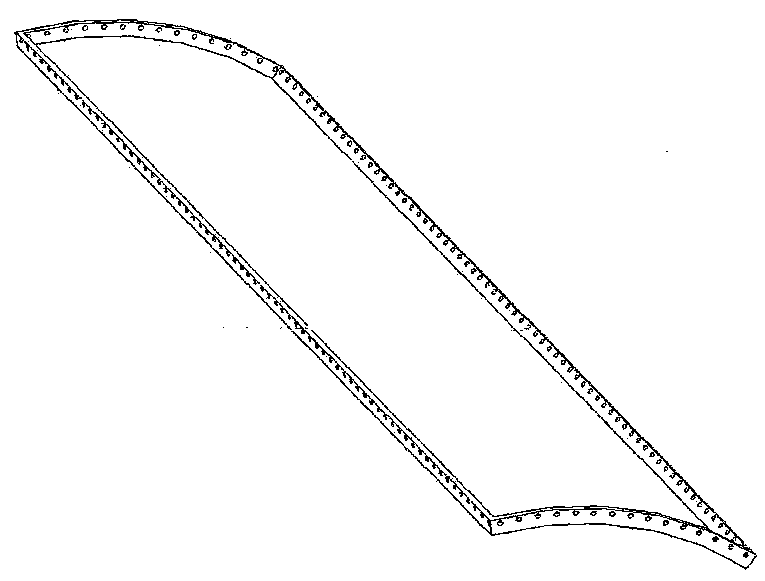

[0023] A plate-shaped module assembled large-scale chemical equipment with anti-corrosion lining, including a number of metal plate-shaped modules 1 with flanges around them, which are connected by bolts; the inner surface of the metal plate-shaped modules and the flange sealing surface Both are lined with an anti-corrosion lining.

[0024] The large-scale chemical equipment refers to storage tanks, storage tanks, reaction towers, reactors or heat exchangers that are difficult to transport by road or rail with a diameter of more than 4 meters or a cross-sectional length × width > 4 meters × 4 meters.

[0025] The anti-corrosion lining layer is a tetrafluoro layer, a polyethylene layer (PE) or a polyolefin layer (PO).

[0026] Adjacent sheet metal modules are joined by flange edges and connected by bolts.

[0027] A method for manufacturing large-scale chemical equipment assembled with plate-shaped modules with anti-corrosion lining, comprising the following steps:

[0028] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com