Simulation system for high-low-temperature environment of controlled flexible cavity body

An environment simulation, high and low temperature technology, applied in the field of flexible cavity simulation system, can solve the problems of huge device, unsuitable for application occasions, unsuitable for miniaturization, low cost, and rapid test application, etc., and achieves no obvious frosting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the embodiment.

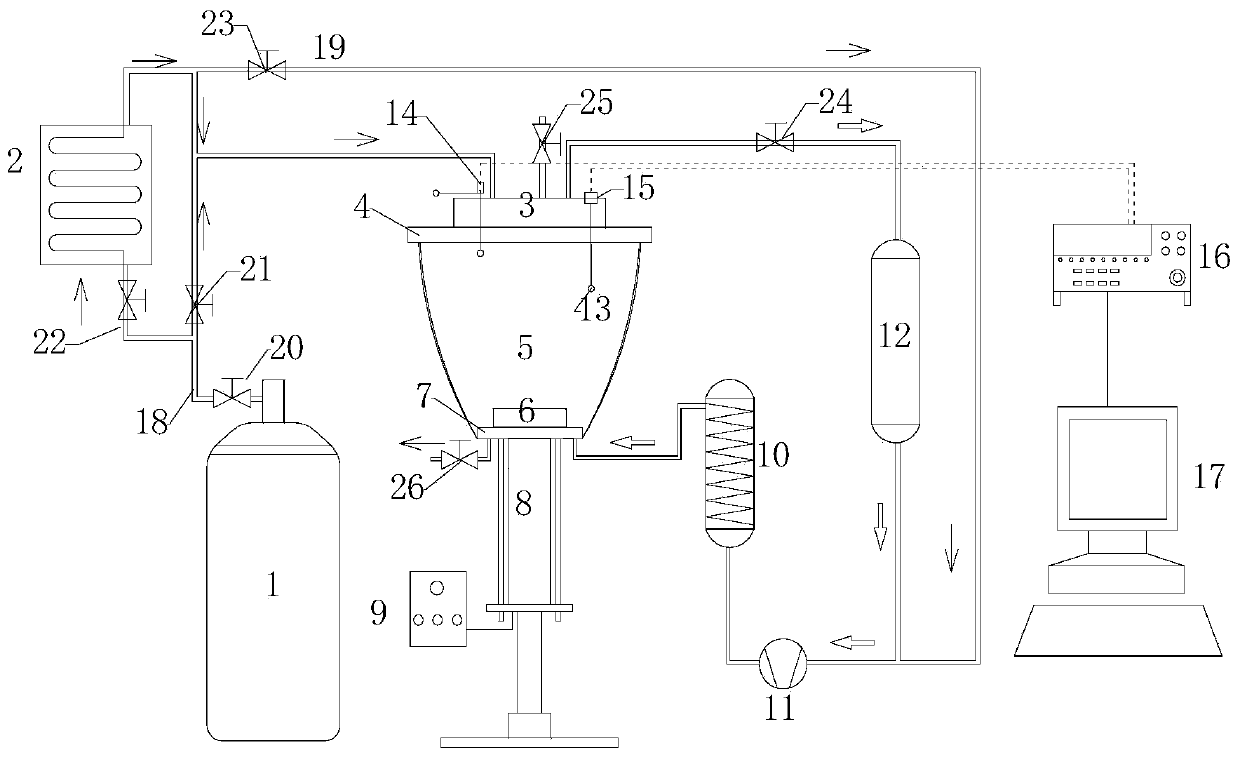

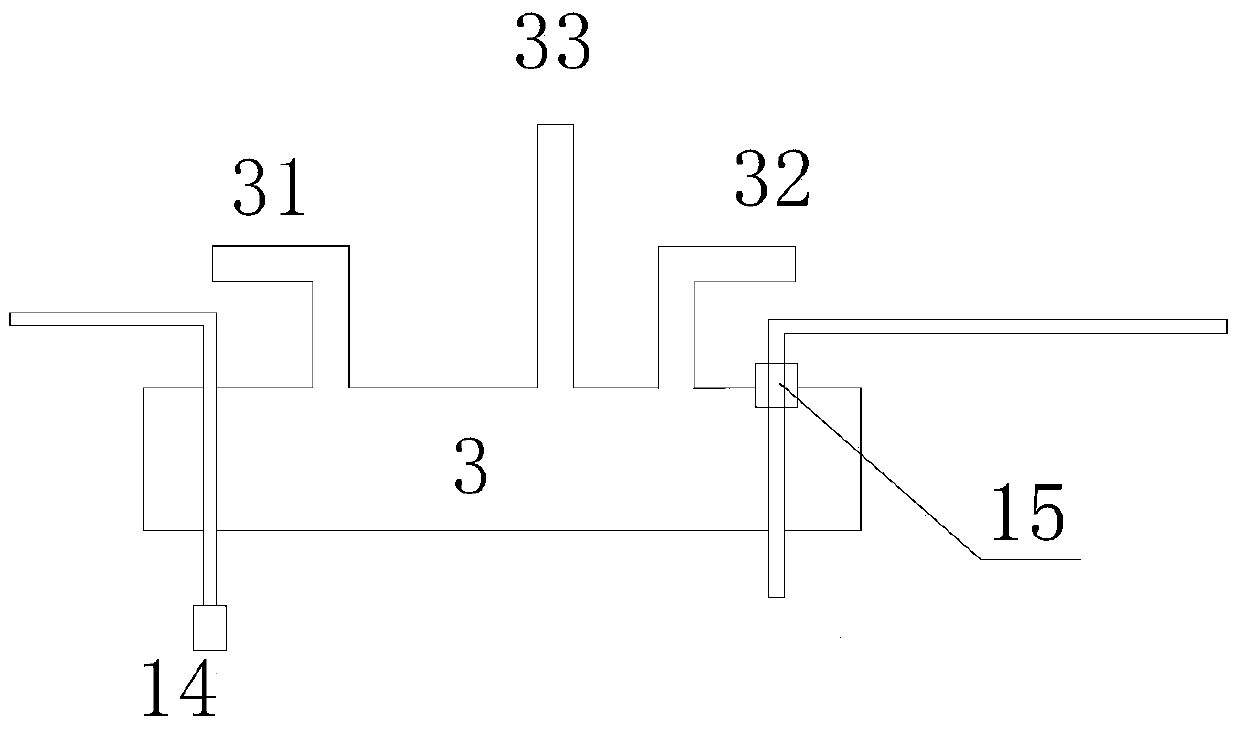

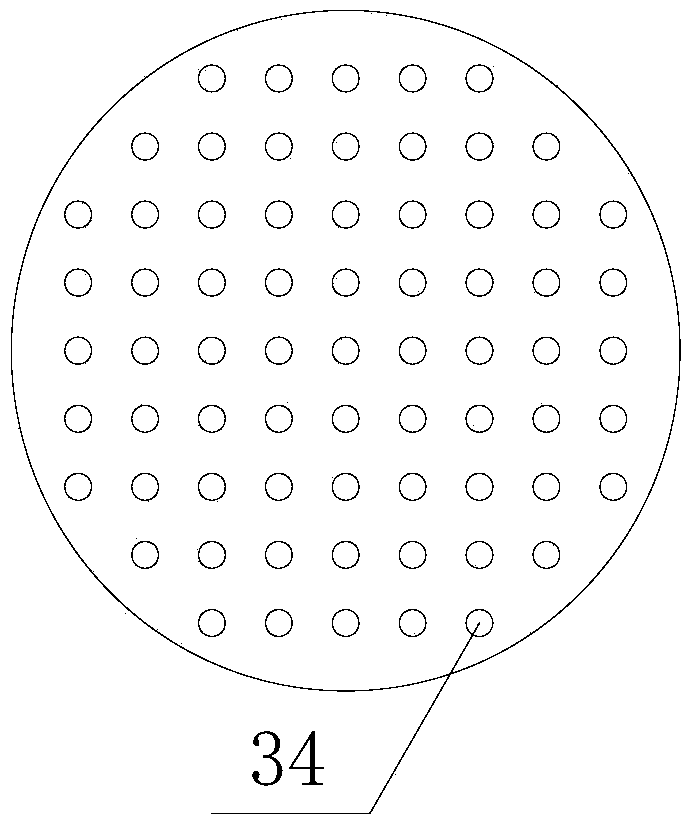

[0039] A controlled flexible space high and low temperature environment simulation system of the present invention such as figure 1 As shown, it includes a low-temperature cold source supply device 1, a vaporizer 2, an upper static plenum 3, an upper fixture 4, a soft cover 5, a lower static plenum 6, a lower fixture 7, a lifting platform device 8, a control box 9, an electric Heater 10, fan 11, gas storage tank 12, temperature sensor 13, micro pressure difference sensor 14, aviation connector 15, data acquisition instrument 16, liquid inlet pipe 18, computer 17, liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com