Crusher for garbage classification

A waste sorting and crusher technology, applied in grain processing, etc., can solve the problems of high waste energy consumption, low crushing strength, slow efficiency, etc., and achieve the effect of large market promotion value and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

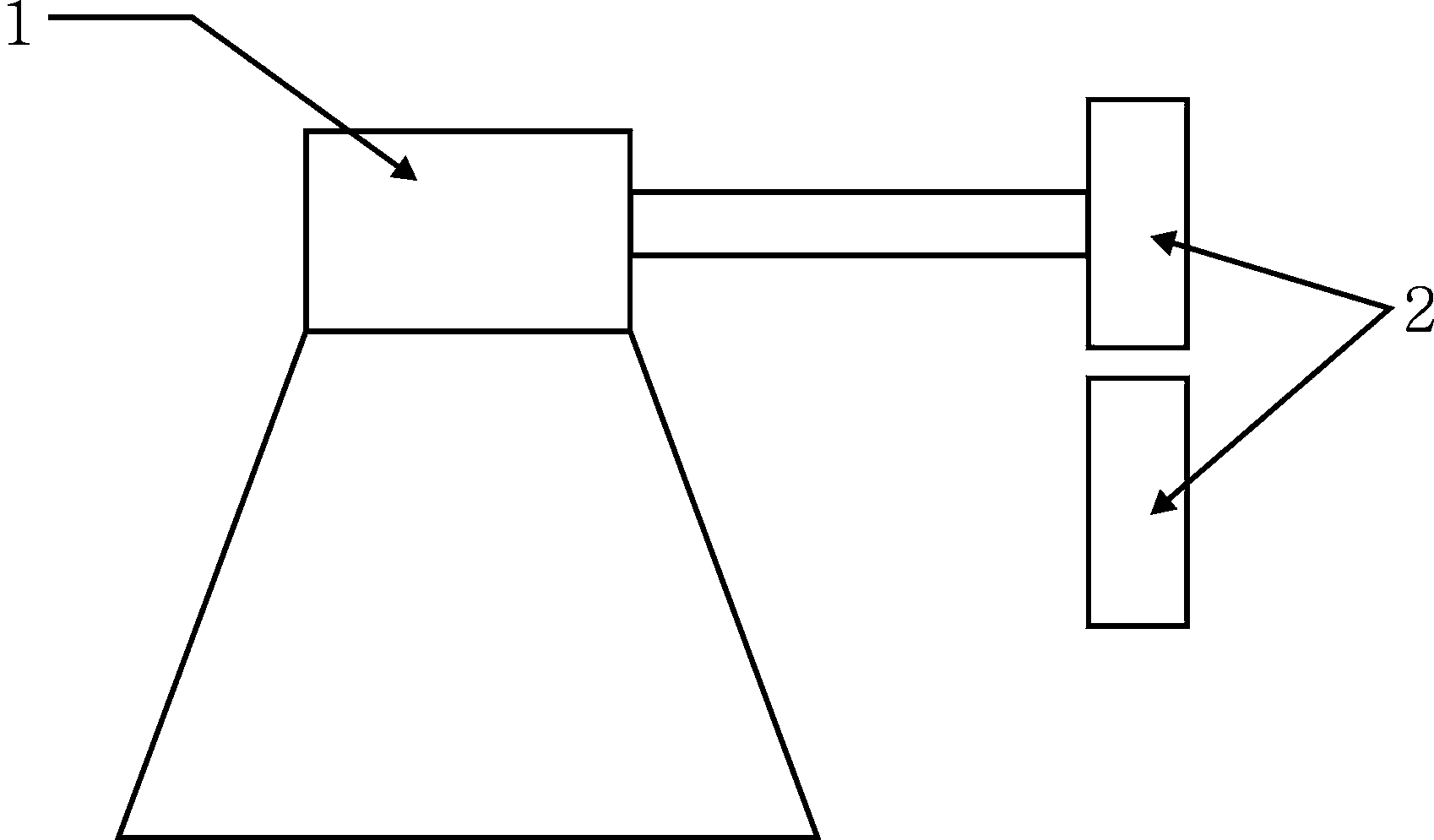

[0013] Such as figure 1 As shown, the present invention includes a motor, the motor is connected to the crushing device through gears, the crushing device includes a crushing wheel, there are several crushing wheels, and a linkage mechanism is provided between the crushing wheel and the crushing wheel; the crushing wheel is gear; there is a gap between the crushing wheel and the crushing wheel, and the gap distance is adjusted by a linkage mechanism.

[0014] The present invention solves the problem that current crushers are not specially used for crushing garbage, and can only be crushed by ore crushers. However, since the hardness of garbage is far lower than that of ore, the required crushing strength is also lower than that of ore. Therefore, the existing The ore crusher is used for the problem of excessive energy consumption and slow efficiency for crushing garbage, and the structure of the invention is simple and practical, and has great market promotion value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com