Metal tube pressure groove knife

A technology of metal pipes and pressure grooves, which is applied to metal processing equipment, accessories of tool holders, and tools used in lathes, etc. It can solve the problems of inconvenient installation and disassembly, easy damage, complex tool structure, etc., and prevent hard extrusion Damage to the workpiece, good adjustability, flexible and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

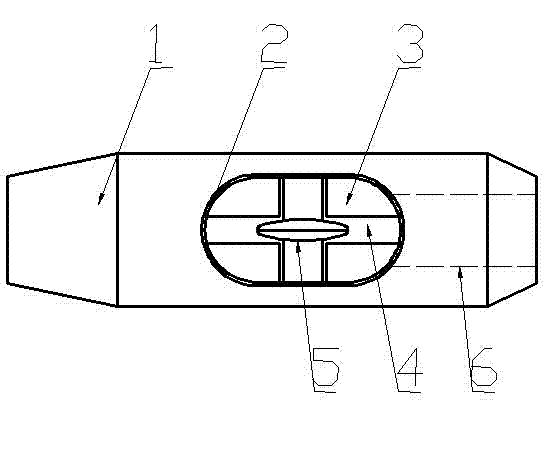

[0013] In the accompanying drawings, a metal pipe grooving knife includes a cylindrical tool body 1 with two ends chamfered; The support 3 of the sipe 4; the grooving cutter head 5 is movable installed in the sipe 4, and the cutter head 5 has a circular cutter with a blade on the edge, and the center of the cutter is provided with a rotating shaft perpendicular to the radial surface of the cutter .

[0014] The support groove 2 is a rectangular groove with two short sides set as semicircles; the shape of the support 3 matches the shape of the support groove 2 .

[0015] The cutter groove 4 includes a cutter groove and a shaft groove, the depth of the cutter groove is smaller than the diameter of the cutter, and the depth of the cutter groove is greater than the depth of the shaft groove.

[0016] A through hole 6 is provided from one end of the cutter main body 1 to the cutter groove 4 , and a push rod for jacking up the bracket 3 and the cutter head 5 can be inserted into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com