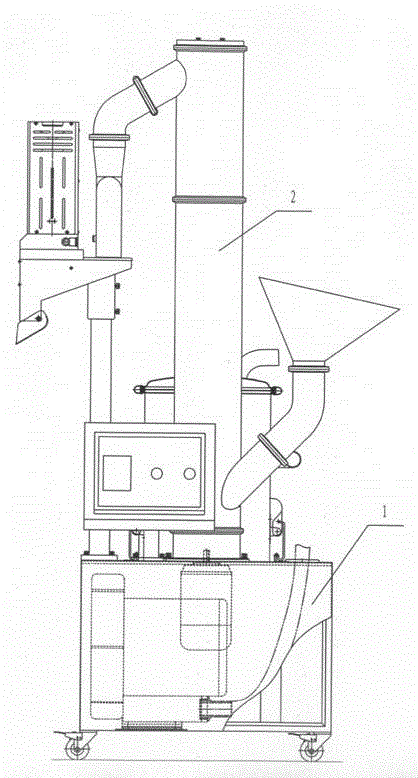

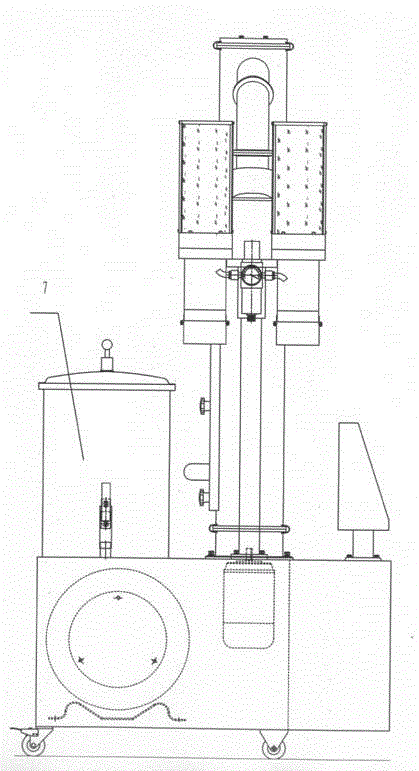

A vertical capsule polishing machine

A polishing machine and capsule technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of occupying a large space, improve feeding efficiency, and highlight substantive features , Thorough polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

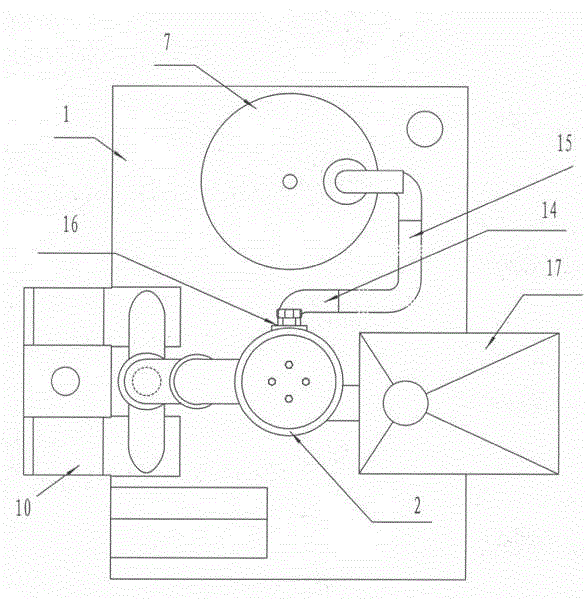

[0023] Referring to the accompanying drawings, a vertical capsule polishing machine in this embodiment includes an organic base 1, the base is provided with a capsule polishing channel 2 (which may be composed of several sections), and the capsule polishing channel is provided with a feeding port 3 and the discharge port 4, the capsule polishing channel is provided with a spiral guide rail 5 and a rotating brush (not shown in the figure) that cooperate with each other to transfer the capsule from the feed port to the discharge port, and the capsule polishing channel 2 is vertically Set on the machine base 1, the side wall of the capsule polishing channel is provided with a through hole 6, and the through hole is connected with a dust suction device 7. Through the interaction of the rotating brush and the spiral guide rail of the capsule polishing channel, the powder on the surface of the capsule is polished. At the same time, the interaction between the rotating brush and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com