Three-in-one treatment tank for wine brewing and treatment method of three-in-one treatment tank

A kind of wine, three-in-one technology, applied in the field of wine brewing, can solve the problems of increased investment in fixed assets, large investment in equipment space costs, increased production costs, etc., to reduce the amount of environmental protection-related processing, reduce the use of floor space, reduce The effect of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

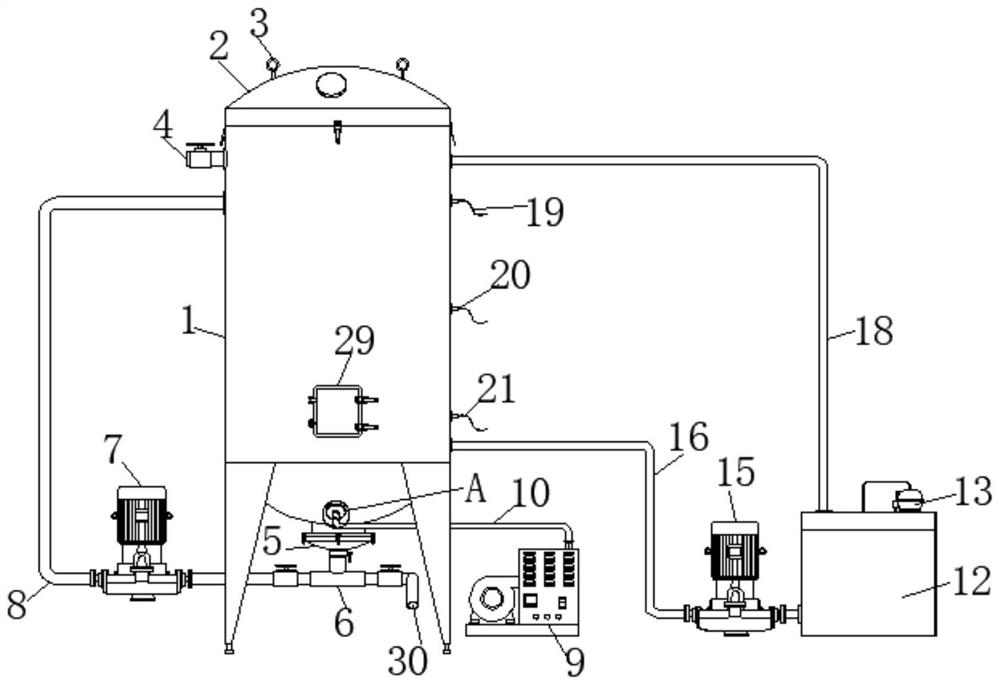

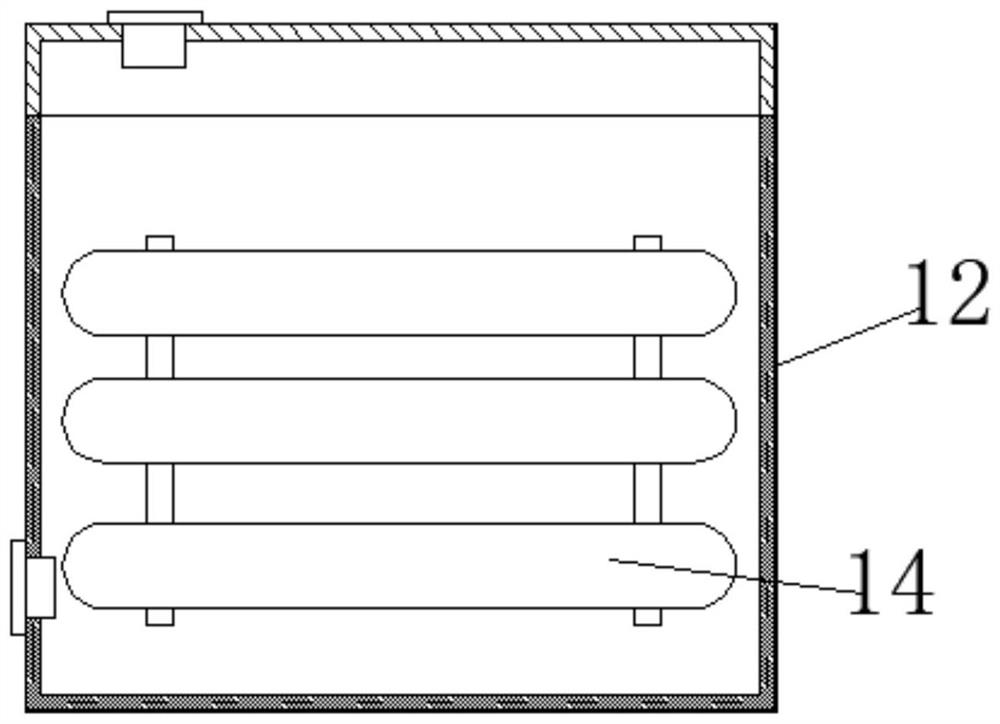

[0038] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a three-in-one processing tank for wine brewing, including a tank body 1; The suspension ring 3 and the ventilation structure used for ventilation on demand, during the oxygen supply process, excess gas can be discharged from the ventilation structure through the ventilation structure;

[0039] The liquid inlet pipe 4 fixedly connected to the side wall of the tank body 1 for feeding; the liquid outlet pipe 5 fixedly connected to the bottom of the tank body 1 for discharging materials, and the end of the liquid outlet pipe 5 far away from the tank body 1 is provided with a tee joint 6 , one of the interfaces of the three-way joint 6 away from the liquid outlet pipe 5 is provided with a collection pipe 30 for collecting the finished wine liquid;

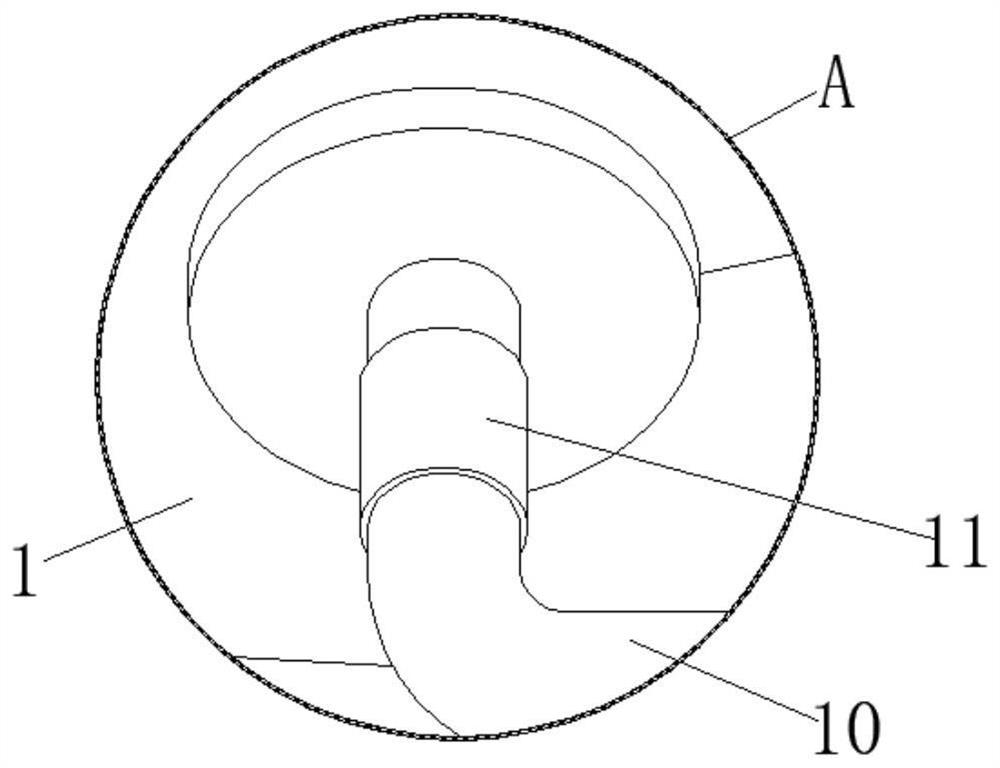

[0040] The skinning assembly is arranged between the three-way joint 6 and the tank body 1 for fully contacting the grape skins with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com