Engagement and disengagement overturning mechanism for accumulation conveyor

A technology of accumulative-free conveyor and turning mechanism, which is applied in the field of transmission structure, can solve the problems of pin shaft and gear damage, damaged guide rail, and trolley non-stop rebound, etc., and achieves the effects of increased braking torque, long life and increased life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

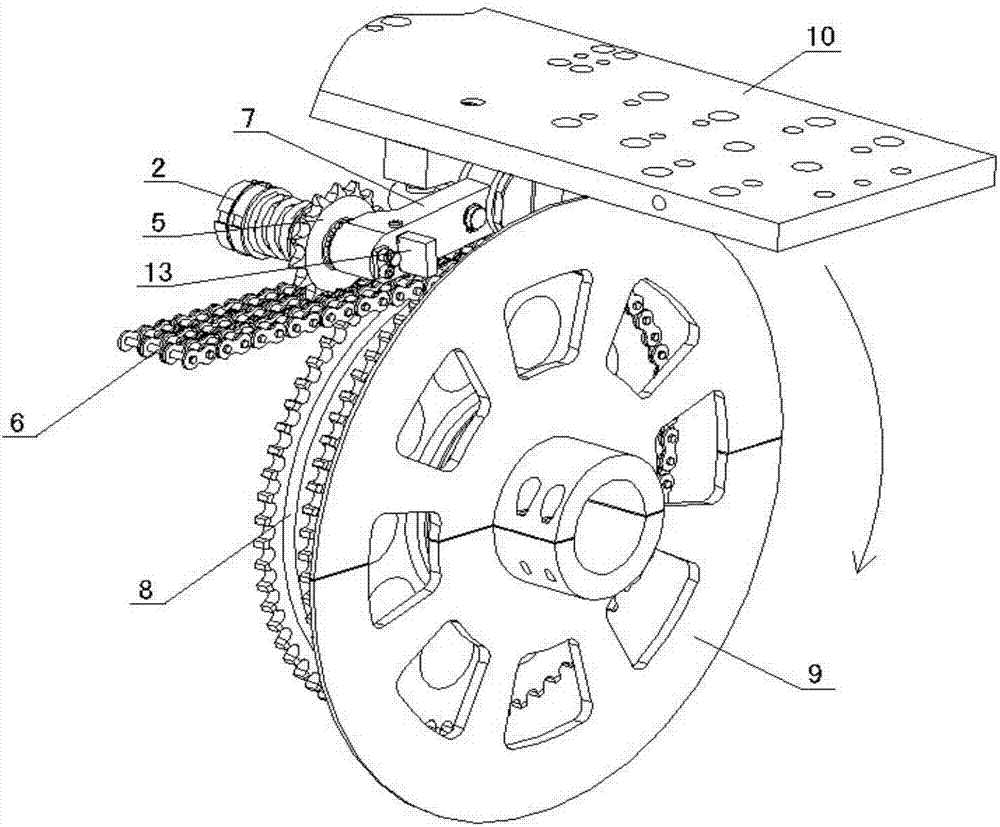

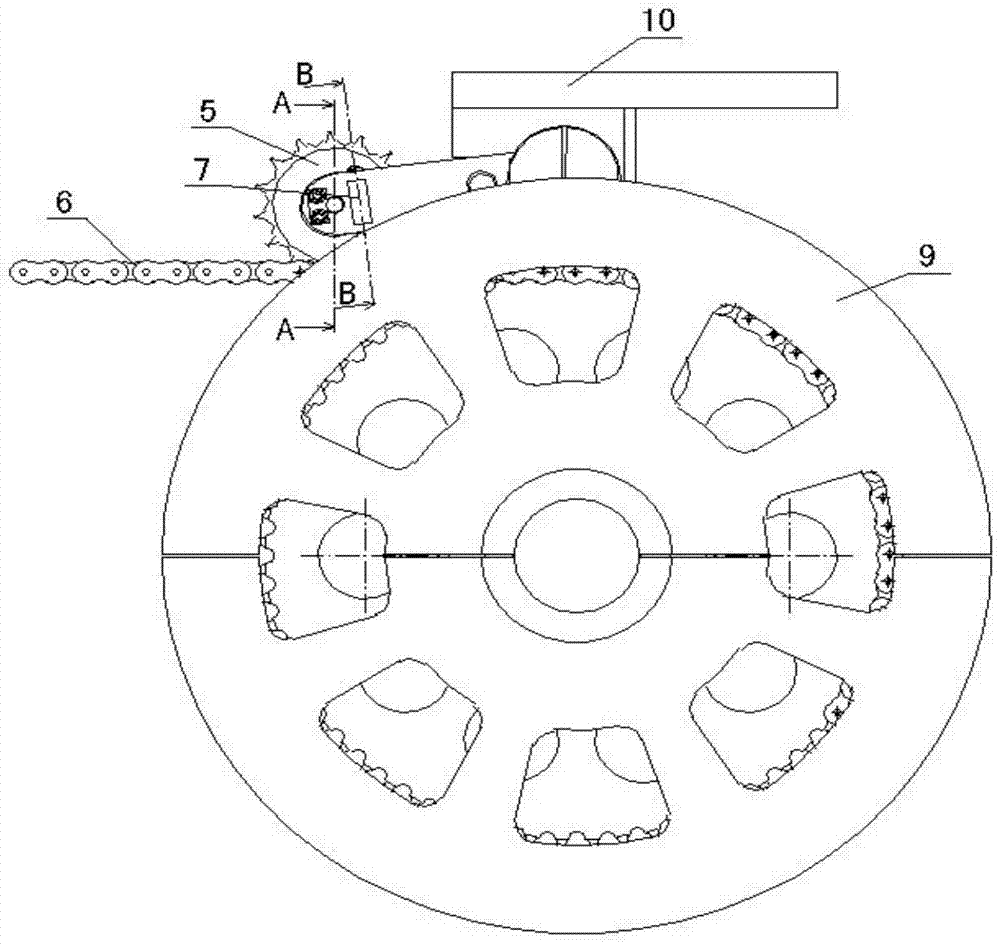

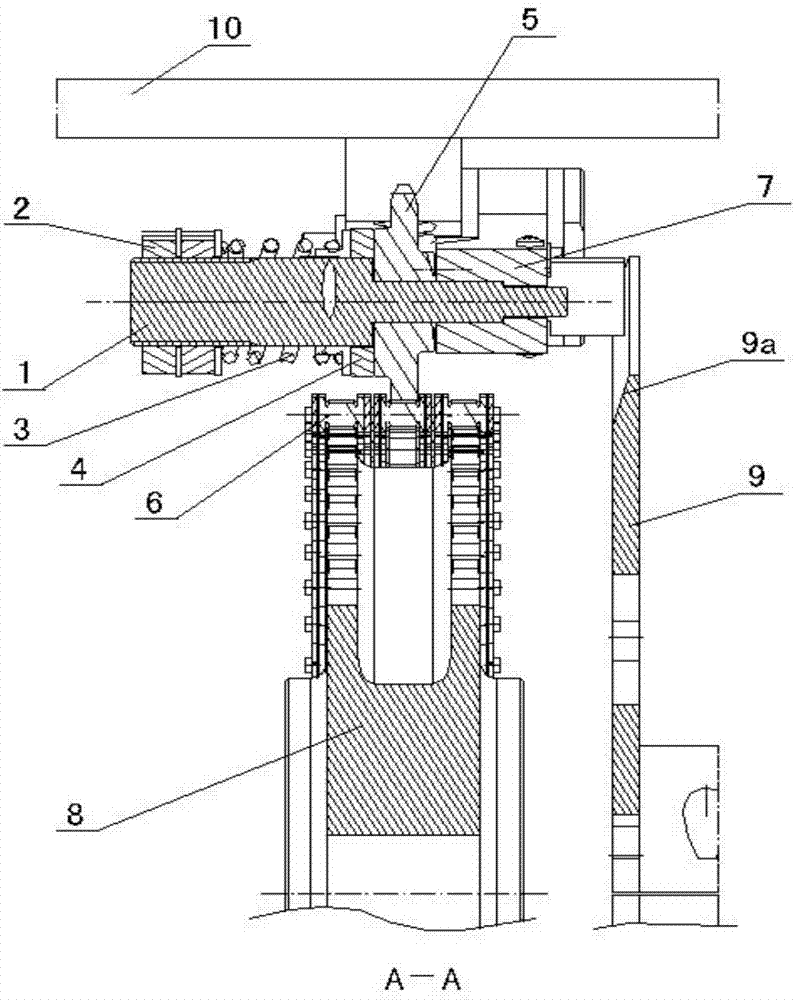

[0022] see figure 1 and figure 2 , the structural form of the clutch and turning mechanism of the product-and-free conveyor in this embodiment is: the compression nut 2 presses the friction plate 4 against the inner end surface of the friction wheel 5 through the compression spring 3 to provide friction, and the friction wheel 5 The sprocket is meshed with the driving chain 6, and the driving chain 6, the friction wheel 5 and the trolley 10 are driven forward synchronously by the sprocket 8, and the trolley 10 is connected with the connecting arm 7 set on the friction wheel shaft 1; The rowing trolley 10 makes relative rotation be formed between the friction wheel 5 and the friction plate 4 and the friction wheel shaft 1 .

[0023] see image 3 and Figure 4 , in the present embodiment, the outer end surface of the friction wheel 5 is provided with an end face toothed plate, and the pressure plate 9 coaxial with the sprocket 8 and synchronously rotated is fixedly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com