Automated mold shelf

A mold shelf and mold technology, applied in the field of shelves, can solve the problems of wasting manpower, low production efficiency, easy damage, etc., and achieve the effect of avoiding damage and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

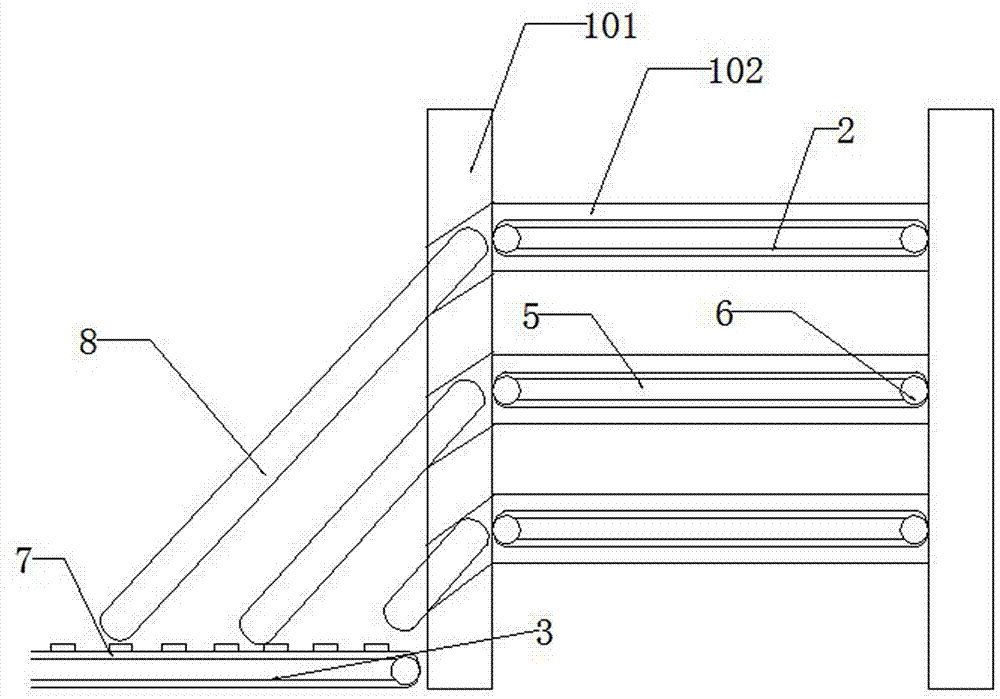

[0023] Embodiment 1: Different molds are placed on different first conveying assemblies 2, and there are multiple first conveying assemblies 2, and the motor is controlled by a central controller, and the motor drives the first conveying assembly 2 to move the molds to the connecting parts, and the slides 8 Transport the mold to the second connector, and the motor drives the second connector to transport the mold to the production line; realizing full automation.

Embodiment 2

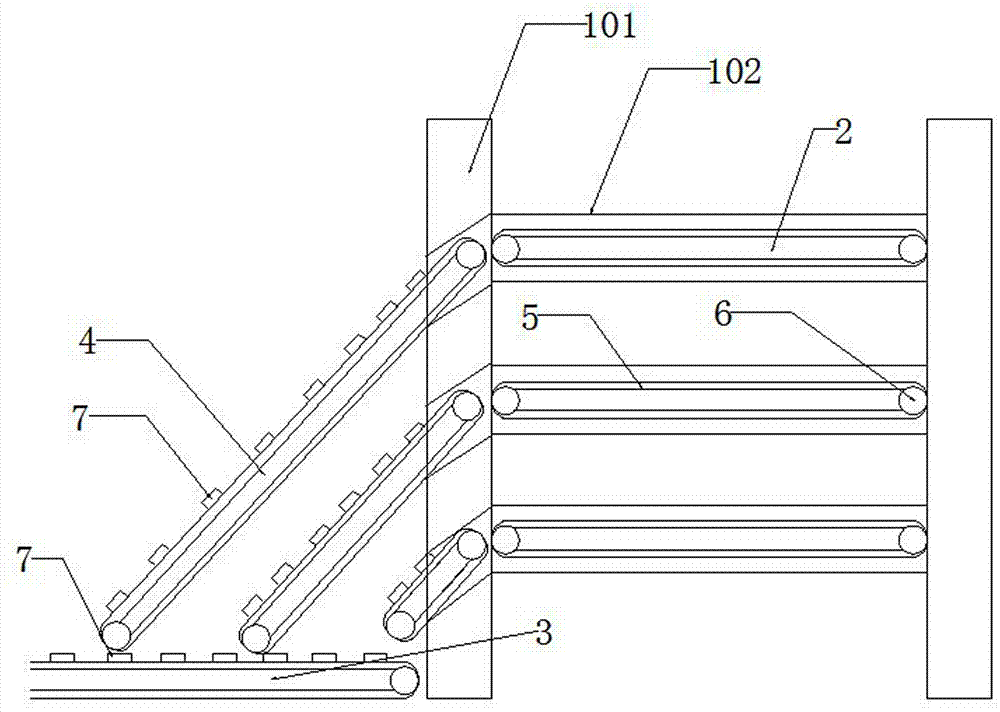

[0024] Embodiment 2: The central controller controls the motor, the motor drives the first transfer assembly 2 to move the mold to the connecting piece, the motor then drives the third connecting piece, the third connecting piece transports the mold to the second connecting piece, and the motor drives the second connecting piece Connecting parts, transport the mold to the production line; realize the whole process of automation.

[0025] The invention provides a shelf for automatically transporting the molds to the production line, which saves manpower and avoids the damage of the molds during the transportation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com