Method for laying sand filling bag frames in shallow water closed area

A closed area and closed area technology, which is applied in the field of filling sand bag frames in shallow water closed areas, can solve the problems of inability to locate the filling bags, inaccessible construction ships, and difficulty in construction by workers, and achieves simple and easy-to-use construction methods, ships and materials. Universal and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

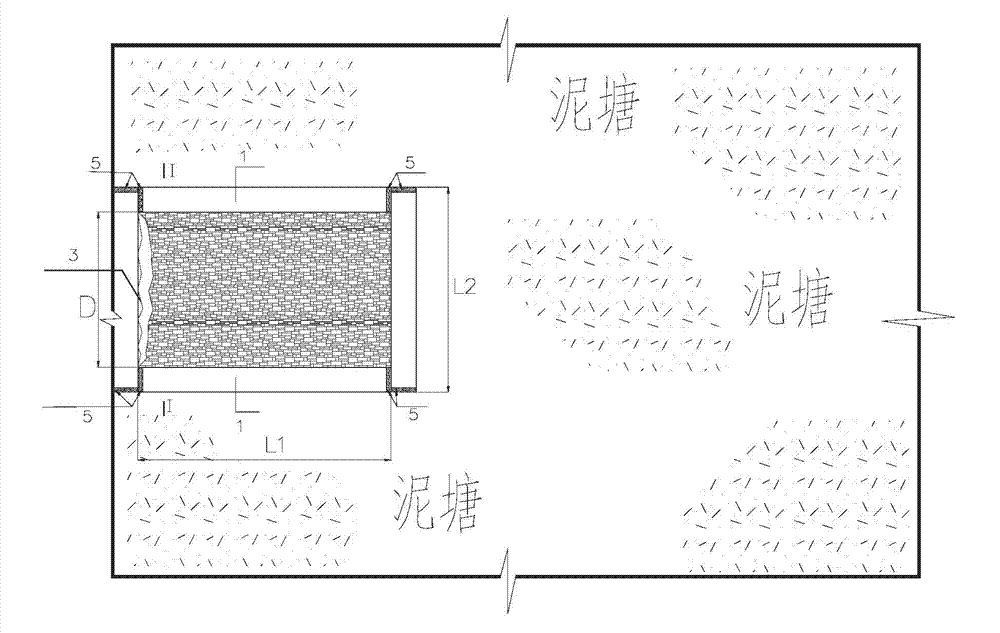

[0023] The method for arranging sand bag frames in shallow water enclosed areas according to the present invention will be described in conjunction with the accompanying drawings.

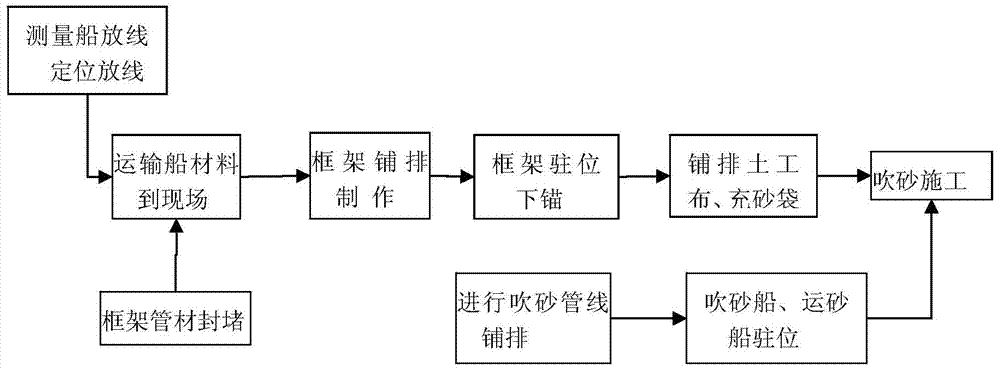

[0024] The method for laying out sand bag frames in shallow water enclosed areas of the present invention includes the following steps:

[0025] 1) Use a small survey boat to enter the shallow water closed area for setting-out positioning, and use buoys to mark the outer boundary of the sand-filled bag frame;

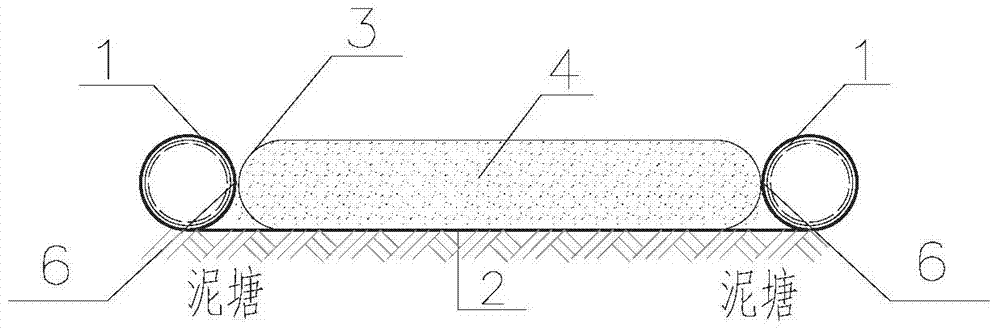

[0026] 2) Transport the corresponding construction materials including the sand blowing pipe 1, and prefabricate multiple sand-filled bags 3;

[0027] 3) Plugging 5 the end of the sand blowing pipe 1 used for the sand filling bag 3;

[0028] 4) Arrange the sand-filled bags 3 in order;

[0029] 5) Use a small ship to transport the sand blowing pipe used for filling the sand bag to the predetermined position, lower the anchor to fix it, and place the sand blowing pipe to the designated posit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap