Oil-gas separator for supercharged engine

A technology of oil-gas separator and supercharged engine, which is applied in the direction of engine lubrication, engine components, machines/engines, etc. It can solve the problems of difficult maintenance, low separation efficiency of oil-gas separator, complicated disassembly process, etc., and reduce oil consumption Quantity, beneficial to the overall layout, and the effect of reducing the layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

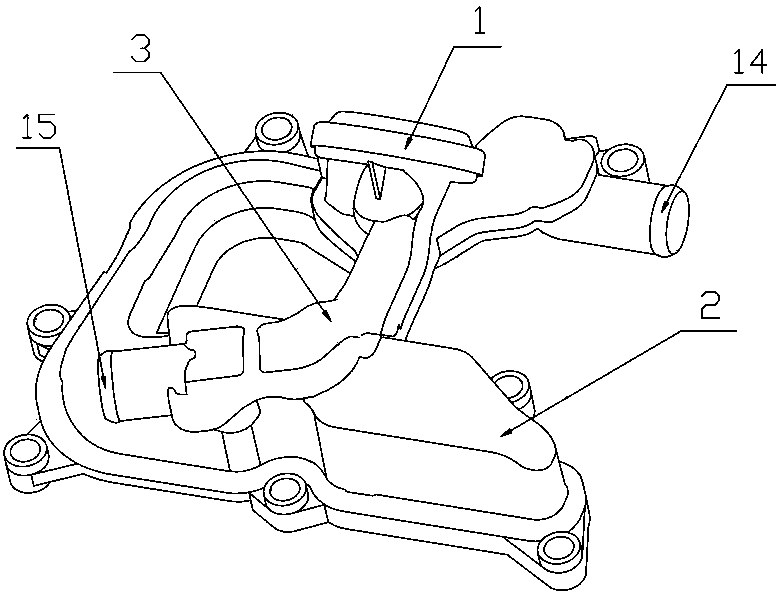

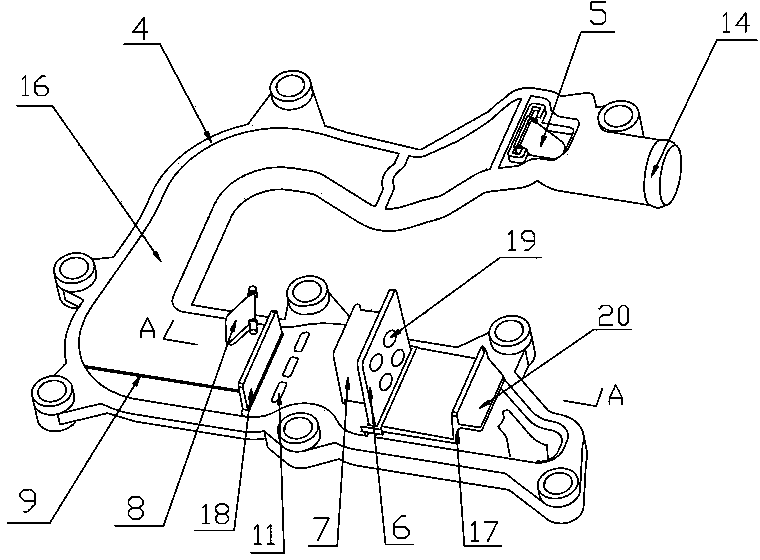

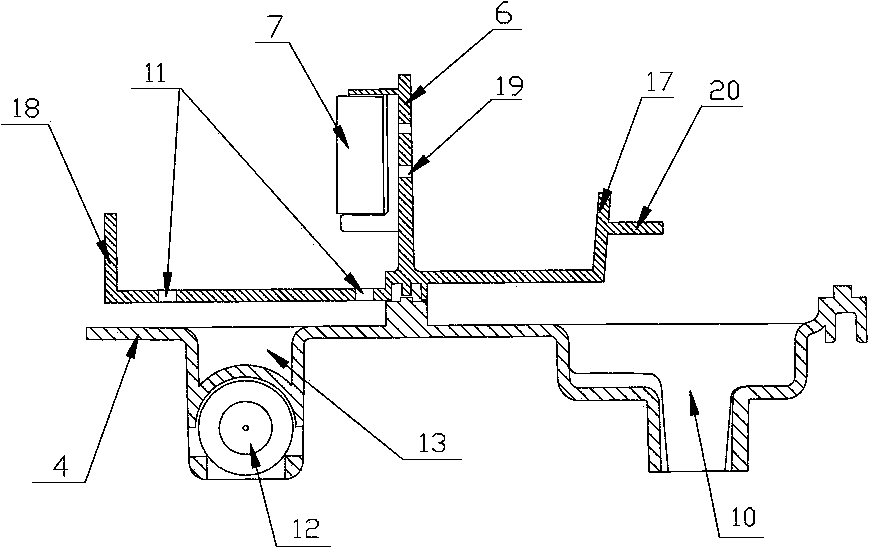

[0019] Such as figure 1 , figure 2 , image 3 The oil-gas separator of the boosted engine shown includes an oil-containing gas inlet 10 , an oil-gas separation passage 16 , an oil outlet 13 and a first gas outlet 14 connected in sequence, and the oil outlet 13 is connected with a funnel-shaped oil outlet 12 . in,

[0020] The oil-gas separation channel 16 is a U-shaped channel whose cross-sectional area gradually decreases along the flow direction of the oil-gas mixture formed by bonding the upper cover plate 2 and the lower cover plate 4; the oil-containing gas inlet 10, the oil outlet 13 and the first gas outlet 14 is arranged on the lower cover plate 4, and the oil-gas separation channel 16 is separated from the oil-containing gas inlet 10 by a partition 6 with a plurality of through holes 19, and the back of the partition 6 is provided with a filter element 7 facing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com