A high-precision calibration plate for camera parameter calibration and its manufacturing method

A production method and camera parameter technology, applied in the field of measurement and control, can solve the problems of small calibration plate size and low point position accuracy, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A high-precision calibration plate for camera parameter calibration of the present invention and its manufacturing method are introduced below in conjunction with the accompanying drawings and embodiments:

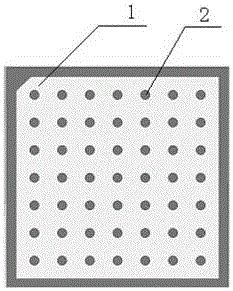

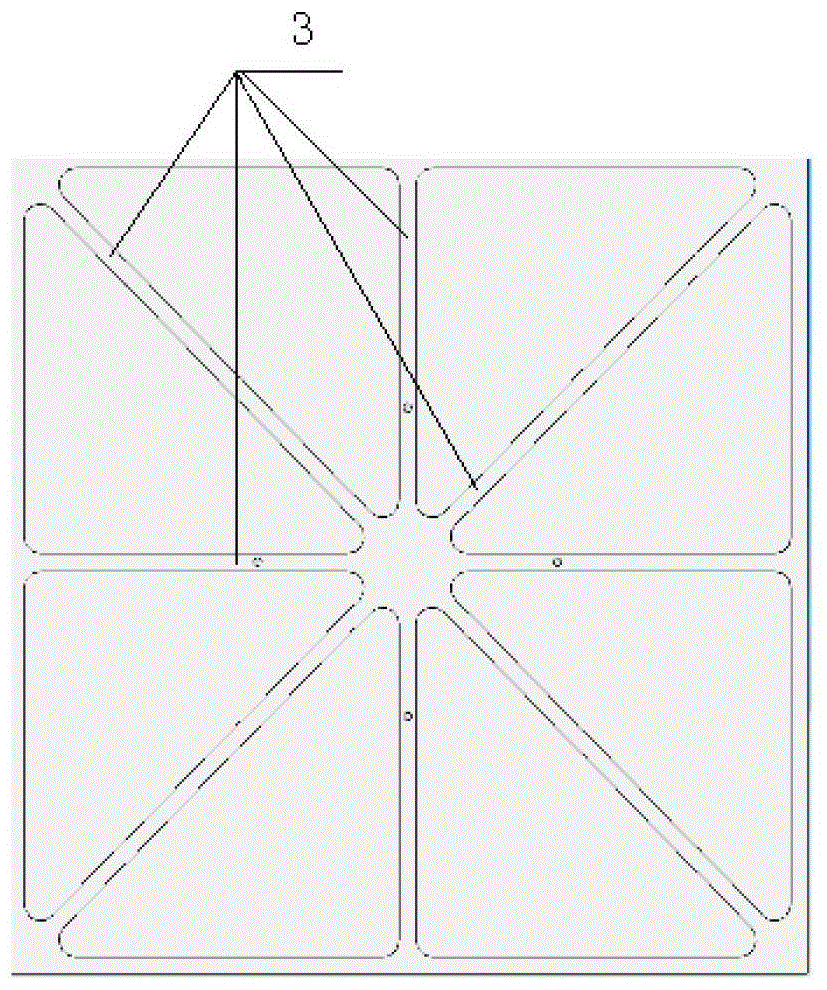

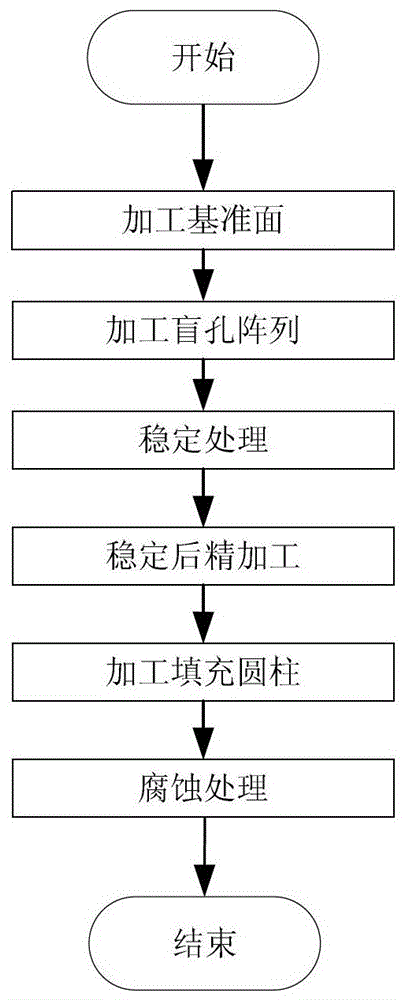

[0035] like figure 1 , 2 As shown, a high-precision calibration plate used for camera parameter calibration includes a calibration plate substrate 1, marking points 2 and ribs 3, the calibration plate substrate 1 is a square metal thin plate, and duralumin is the best. Marking points 2 are uniformly arranged on the front of the calibration plate substrate 1 to form an array of marking points. The distance between the geometric centers of adjacent marking points 2 is selected according to actual needs. The accuracy of the distance between the geometric centers of adjacent marking points 2 is within the range of ±0.02mm. 2 Roundness φ0.01mm. A reinforcing rib 3 is installed on the back side of the calibration plate substrate, and the material of the reinforcing rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com