Laser residual thermal deformation correction method for track deformation of split arc rolling guide rail

A technology of rolling guide rail and correction method, which is applied to the improvement of process efficiency, forming tools, metal processing equipment, etc. It can solve problems such as difficulties, complicated installation and adjustment process, and large number of segments, so as to reduce the scrap rate and reduce the number of segments Number, the effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

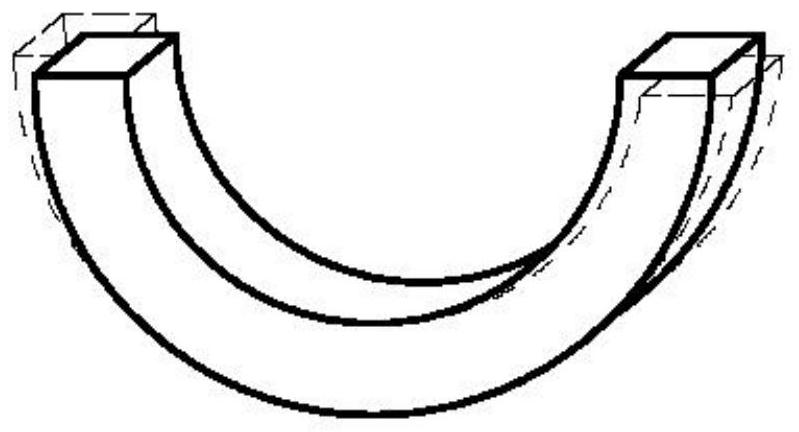

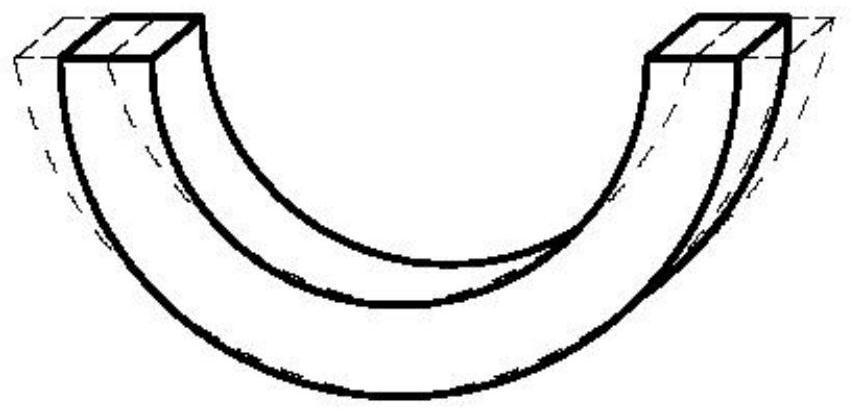

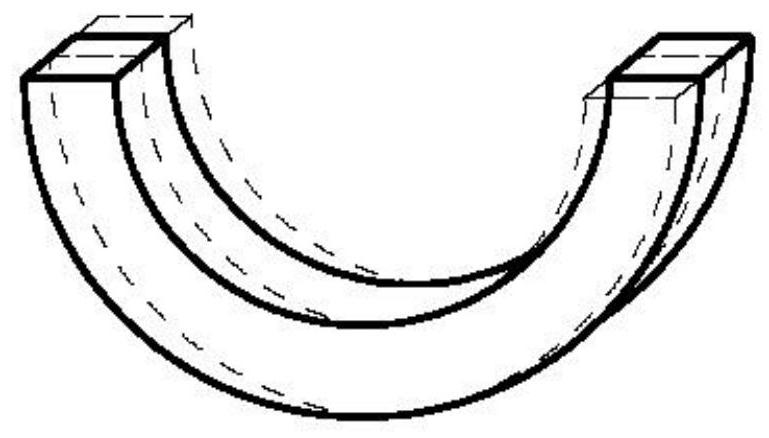

[0032] The laser residual thermal deformation correction method for the track deformation of the split arc rolling guide rail of the present invention, the specific process is: the arc opening becomes larger, the inner wall of the arc track is scanned with a laser, the arc opening becomes smaller, and the outer wall of the arc track is scanned with a laser ;The laser power can change the metallographic structure of the track wall; the laser power will not cause excessive opening deformation; for the overall opening deformation of the track, if the surface is continuously irradiated with the laser, the heat energy distribution obtained on the surface is small at both ends and large at the middle; constant, the speed of the laser beam scanning the surface changes, the speed at both ends of the track is fast, and the middle is slow, so that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com