Crack evolution test method of floor strata solid-fluid coupling material

A technology of crack evolution and test method, which is applied in the field of crack evolution test of solid-fluid coupling materials in floor rocks, and can solve problems such as inability to accurately apply solid-fluid coupling model tests, failure to reflect the use of similar materials, and not similar simulation of solid-fluid coupling , to achieve good viscosity and sealing, convenient lubrication, and promote the effect of full fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

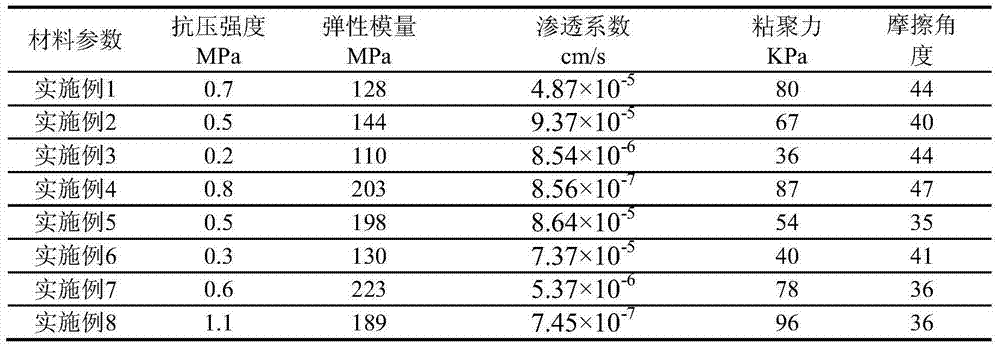

Embodiment 1

[0031] Weigh sand, paraffin wax, hydraulic oil, calcium carbonate, asphalt, and petroleum jelly in proportion to a total weight of 1000 grams. The weights of each component are: 790 grams of sand, 50 grams of paraffin, 39 grams of hydraulic oil, and 65 grams of calcium carbonate. 41 grams of petroleum jelly, 15 grams of asphalt;

[0032] The development method of solid-fluid coupling material for floor rock layer includes the following steps:

[0033] 1) Weigh out sand, paraffin, hydraulic oil, calcium carbonate, asphalt, and petroleum jelly in proportion;

[0034] 2) Put paraffin, hydraulic oil, asphalt, and petroleum jelly in a heating container at 110°C to melt and stir evenly;

[0035] 3) After mixing the sand and calcium carbonate in a mixer, put them into a heating container and stir together with melted paraffin, hydraulic oil, asphalt, and petroleum jelly, and stir at 100°C for 3 to 5 minutes;

[0036] 4) Put the mixed material into the standard test piece forming mold for comp...

Embodiment 2

[0039] Weigh sand, paraffin wax, hydraulic oil, calcium carbonate, asphalt, and petroleum jelly in proportion to a total weight of 1000 grams. The weight of each component is: sand 730 grams, paraffin wax 90 grams, hydraulic oil 49 grams, and calcium carbonate 75 grams. 50 grams of petroleum jelly, 6 grams of asphalt;

[0040] The development method of solid-fluid coupling material for floor rock layer includes the following steps:

[0041] 1) Weigh out sand, paraffin, hydraulic oil, calcium carbonate, asphalt, and petroleum jelly in proportion;

[0042] 2) Put paraffin, hydraulic oil, asphalt, and petroleum jelly in a heating container at 110°C to melt and stir evenly;

[0043] 3) After mixing the sand and calcium carbonate in a mixer, put them into a heating container and stir together with melted paraffin, hydraulic oil, asphalt, and petroleum jelly, and stir at 100°C for 3 to 5 minutes;

[0044] 4) Put the mixed material into the standard test piece forming mold for compaction, and...

Embodiment 3

[0047] Weigh sand, paraffin wax, hydraulic oil, calcium carbonate, asphalt, and petroleum jelly in proportion to a total weight of 1000 grams. The weight of each component is: 805 grams of sand, 75 grams of paraffin, 20 grams of hydraulic oil, and 65 grams of calcium carbonate. 25 grams of petroleum jelly, 10 grams of asphalt;

[0048] The development method of solid-fluid coupling material for floor rock layer includes the following steps:

[0049] 1) Weigh out sand, paraffin, hydraulic oil, calcium carbonate, asphalt, and petroleum jelly in proportion;

[0050] 2) Put paraffin, hydraulic oil, asphalt, and petroleum jelly in a heating container at 110°C to melt and stir evenly;

[0051] 3) After mixing the sand and calcium carbonate in a mixer, put them into a heating container and stir together with melted paraffin, hydraulic oil, asphalt, and petroleum jelly, and stir at 100°C for 3 to 5 minutes;

[0052] 4) Put the mixed material into the standard test piece forming mold for compac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com