Refractory slurry powder for air brick

A technology of refractory mud and breathable bricks, which is applied in the field of refractory mud powder for breathable bricks, which can solve the problems of inconvenient replacement, large shrinkage, steel seepage, etc., and achieve the effect of easy application, good moisture retention and easy pulling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

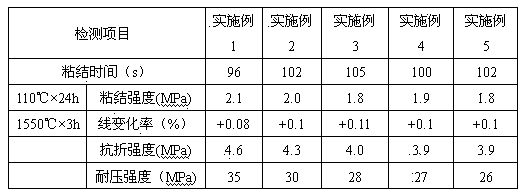

Examples

Embodiment 1

[0027] A kind of refractory mud powder for air-permeable brick, its weight percentage is composed of: quartz sand 80%, earthy graphite 3%, active SiO 2 Micropowder 2%, bentonite 5%, soft clay 9%, methylcellulose 0.5%, dextrin 0.5% and 0.2% sodium tripolyphosphate of the total weight of the above components.

[0028] Among the above components, 50% of the quartz sand is 0~0.5mm granular material, 30% of the quartz sand is a fine powder with a particle size of -200 mesh, and the remaining components are -180 mesh, -200 mesh, and -320 mesh. One or more fine powders of mesh and -325 mesh.

Embodiment 2

[0030] A kind of refractory mud powder for air-permeable brick, its weight percentage is composed of: quartz sand 80%, earthy graphite 5%, active α-Al 2 o 3 Micropowder 3%, bentonite 4%, soft clay 7%, methylcellulose 0.5%, dextrin 0.5% and 0.2% sodium tripolyphosphate of the total weight of the above components.

[0031] Among the above components, 50% of the quartz sand is 0~0.5mm granular material, 30% of the quartz sand is a fine powder with a particle size of -200 mesh, and the remaining components are -180 mesh, -200 mesh, and -320 mesh. One or more fine powders of mesh and -325 mesh.

Embodiment 3

[0033] A kind of refractory mud powder for air-permeable brick, its weight percentage is composed of: quartz sand 80%, flake graphite 5%, active SiO 2 Micropowder 2%, bentonite 4%, soft clay 8%, methylcellulose 0.5%, dextrin 0.5% and 0.2% sodium tripolyphosphate of the total weight of the above components.

[0034] Among the above components, 50% of the quartz sand is 0~0.5mm granular material, 30% of the quartz sand is a fine powder with a particle size of -200 mesh, and the remaining components are -180 mesh, -200 mesh, and -320 mesh. One or more fine powders of mesh and -325 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com