A method for degrading, obtaining and detecting chondroitin sulfate and hyaluronic acid disaccharide

A chondroitin sulfate and hyaluronic acid technology, applied in the field of medicine, can solve the problems of loss of relative content information, poor repeatability of analysis results, cumbersome detection steps, etc., and achieve the effects of short detection time, low requirements for experimental instruments and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

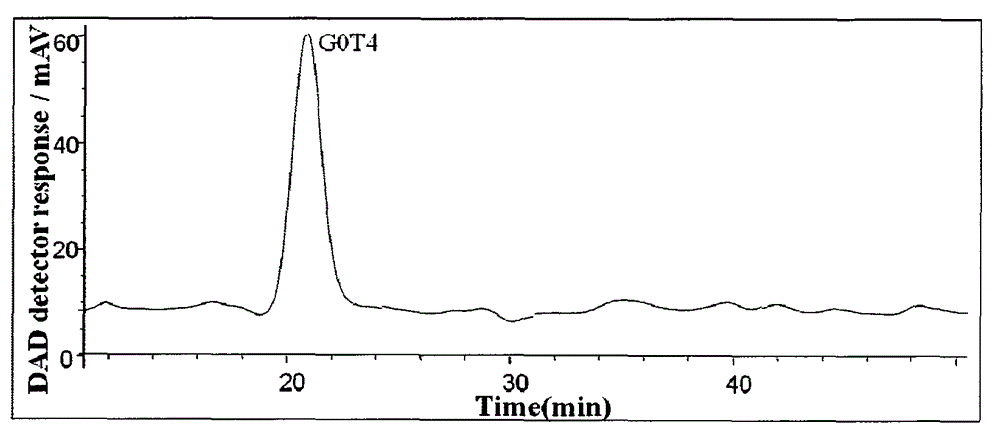

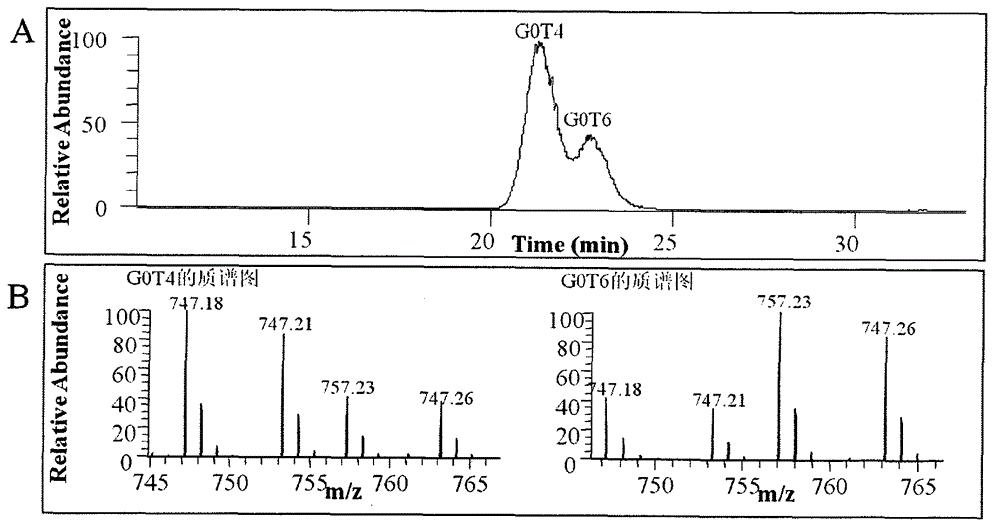

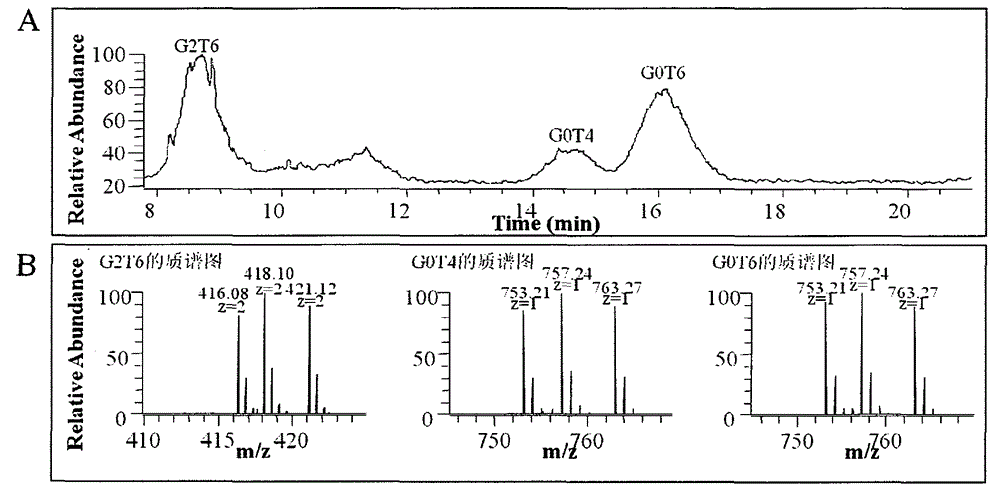

[0035] The chemical degradation method of embodiment 1 chondroitin sulfate class sample disaccharide

[0036] (1) Dissolve 1mg chondroitin sulfate in 500uL containing 10% N 2 h 4 ·H 2 SO 4 N 2 h 4 ·H 2 O solution, heated to dissolve, then sealed and heated to 98 ° C, reacted for 9 hours, after the reaction was completed, freeze-dried to remove N 2 h 4 Deacetylated chondroitin sulfate;

[0037] (2) Dissolve the deacetylated chondroitin sulfate obtained in step (1) in 50uL water, add 50uL sodium nitrite aqueous solution with a pH of 1.5, adjust the pH to 4.0 after reacting at 0-5°C for 10 minutes, and add 50uL sodium nitrite solution with a pH of 4.0 Nitrous acid, react at 0-5°C for 10 minutes, add 30uL ammonia water to terminate the reaction.

Embodiment 2

[0038] The chemical degradation method of embodiment 2 chondroitin sulfate class sample disaccharide

[0039] (1) Dissolve 1 mg of chondroitin sulfate in 1 mL containing 10% N 2 h 4 ·H 2 SO 4 N 2 h 4 ·H 2 O solution, heated to dissolve, then sealed and heated to 90 ° C, reacted for 5 hours, after the reaction was completed, freeze-dried to remove N 2 h 4 Deacetylated chondroitin sulfate;

[0040](2) Dissolve the deacetylated chondroitin sulfate obtained in step (1) in 50uL of water, add 50uL of sodium nitrite aqueous solution with a pH of 1.5, react at 0-5°C for 10 minutes, adjust the pH to 4.0, add 50uL with a pH of 4.0 The nitrous acid was reacted at 0-5°C for 10 minutes, and 30uL of ammonia water was added to terminate the reaction.

Embodiment 3

[0041] The chemical degradation method of embodiment 3 chondroitin sulfate class sample disaccharide

[0042] (1) Dissolve 1 mg of chondroitin sulfate in 1 mL containing 10% N 2 h 4 ·H 2 SO 4 N 2 h 4 ·H 2 O solution, heated to dissolve, then sealed and heated to 110°C, reacted for 16 hours, after the reaction was completed, freeze-dried to remove N 2 h 4 Deacetylated chondroitin sulfate;

[0043] (2) Dissolve the deacetylated chondroitin sulfate obtained in step (1) in 50uL water, add 50uL sodium nitrite aqueous solution with a pH of 1.5, adjust the pH to 4.0 after reacting at 0-5°C for 10 minutes, and add 50uL sodium nitrite solution with a pH of 4.0 Nitrous acid, react at 0-5°C for 10 minutes, add 30uL ammonia water to terminate the reaction.

[0044] Table 1 Analysis of chondroitin sulfate chemical degradation products

[0045]

[0046] The results show that CS can be completely chemically degraded in Examples 1 and 3, and the time spent in Example 1 is 43.8% l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com