Device and method for acquiring off-line data of MES (Manufacturing Execution Method) system

A manufacturing execution system and data acquisition unit technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of production workshop failure, loss, and equipment data collection failure, so as to reduce losses and ensure normal operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

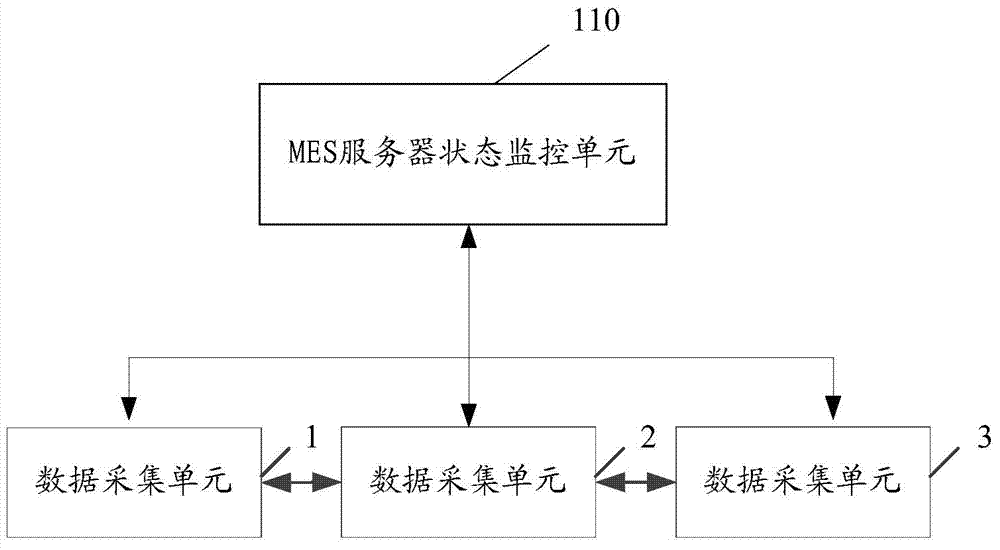

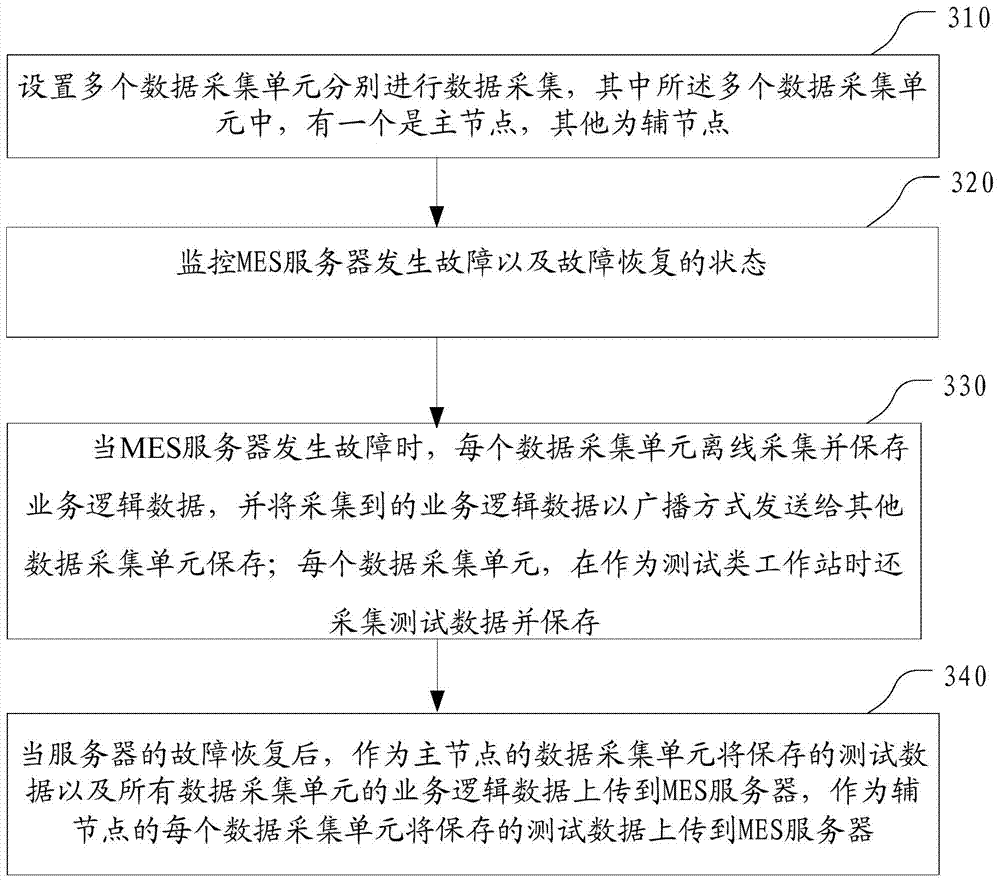

[0030] In the MES system, when the MES server does not fail, each data acquisition unit directly communicates with the MES server, and directly uploads the collected data to the MES server to ensure normal production. Once the MES server fails, each data acquisition unit cannot send the collected data to the MES server, which may lead to paralysis of production and cause certain economic losses to the enterprise.

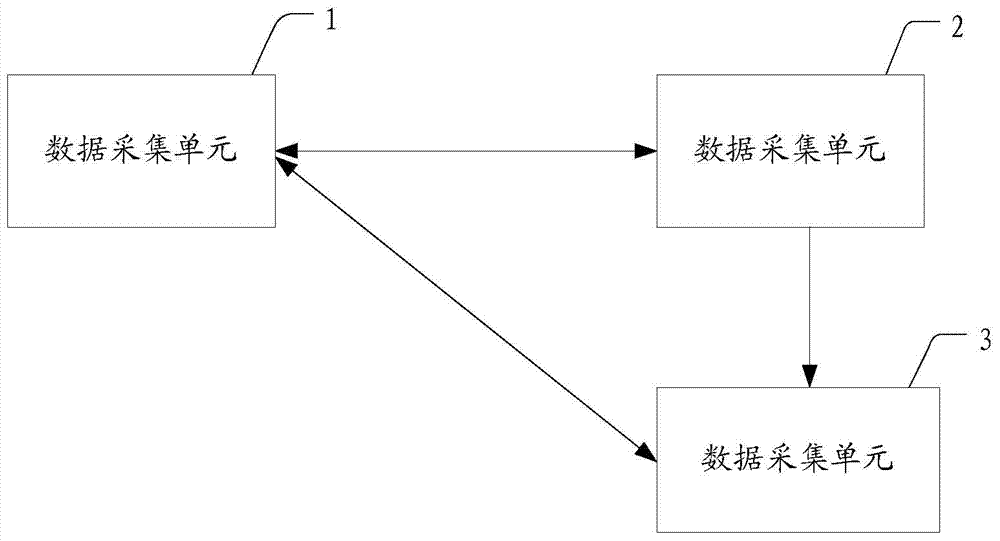

[0031] The core idea of the present invention is to provide a method of using distributed data collection and processing technology when the MES server fails in the offline mode in the MES system, and broadcast the production data stored in each data collection unit locally to others. All data acquisition units realize data synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com