Ground guiding wire traveling crane

A technology of ground wires and walking wheels, applied in the direction of overhead lines/cable equipment, etc., which can solve the problems of life safety hazards for maintenance personnel, long time required for operations, and inability to be widely used, achieving high safety and improving use safety , The effect of improving the reliability and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

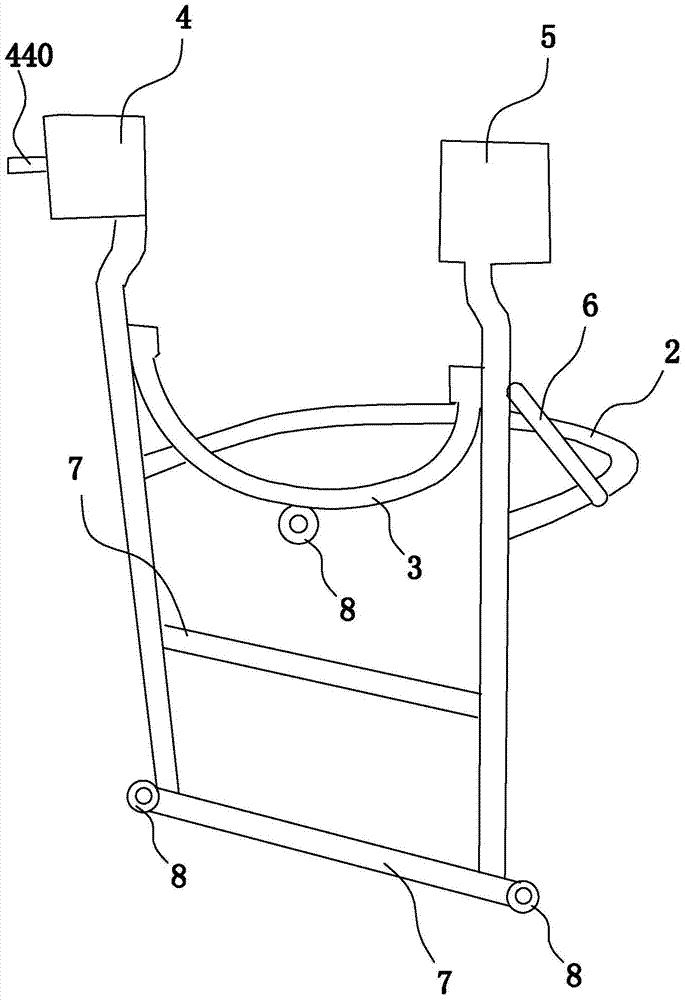

[0019] Embodiment: driving with ground wire, which is characterized in that it includes a base 1, a base body 2 arranged on the base body and a guardrail 3 matched with the base body 2, and a walking device and a braking device are respectively provided on both sides of the base , The traveling device 4 and the braking device 5 are respectively provided with a first traveling wheel 41 and a second traveling wheel 51 . In order to facilitate the laying of the maintenance personnel's feet and save labor, two crosspieces 7 arranged up and down are arranged under the base 1 .

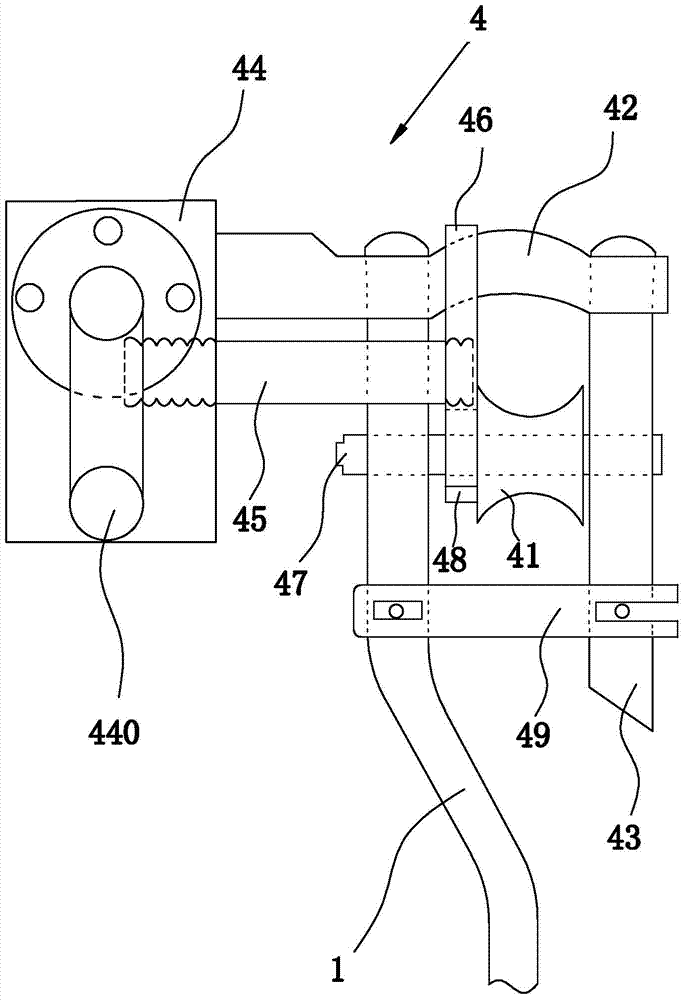

[0020] The running device 4 includes a first driving jack 42 fixed on the upper end of one side of the base 1, a first driving side bar 43 vertically arranged at one end of the first driving jack 42, fixed on the first row The gearbox 44 at the other end of the roof rod 42, the transmission gear 46 connected to the gearbox 44 through the driving transmission shaft 45, and the driven gear 48 meshed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com