Simple Brine Filter

A filter and brine technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of incomplete removal of rust, waste of maintenance costs, freezing construction damage, etc., easy to popularize and use, and low labor intensity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

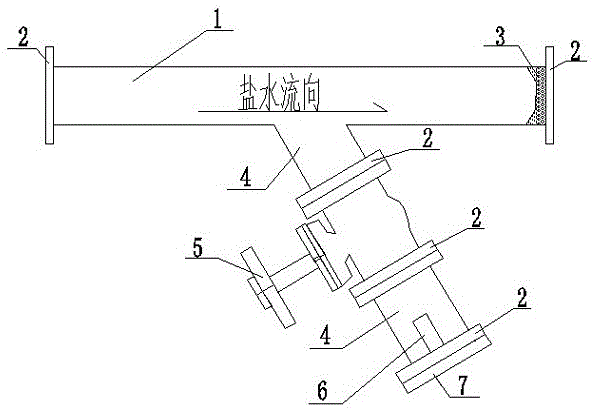

[0011] Such as figure 1 , the present invention it comprises main pipe 1, valve 5 and cover plate 7. It is characterized in that: the two sides of the main pipe 1 are welded with connecting flanges 2, and a filter screen 3 is arranged at the connecting flange 2 at the end of the main pipe 1 where the brine flows. A side passage pipe 4 is arranged on the side of the main pipe 1 , and the side passage pipe 4 is provided with two sections, and the two sections of the side passage pipe 4 are connected by a valve 5 . The end of the side pipe 4 is connected to the cover plate 7 through the connecting flange 2; the inside of the cover plate (7) is provided with an adsorption magnet.

[0012] The two sections of side pipes 4 are connected to the valve 5 through connecting flanges 2 and bolts.

[0013] The connecting flange 2 at the end of the side passage pipe 4 is connected to the cover plate 7 by bolts.

[0014] During use, the filter is connected with the brine main pipe by bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com