Ultrasonic cleaning device for plastic part and working method thereof

A cleaning device and ultrasonic technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of affecting the silk screen printing effect of plastic parts, easily scratching the surface of plastic parts, and poor cleaning effect, etc. , to achieve the effect of simple structure, scientific and reasonable design, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

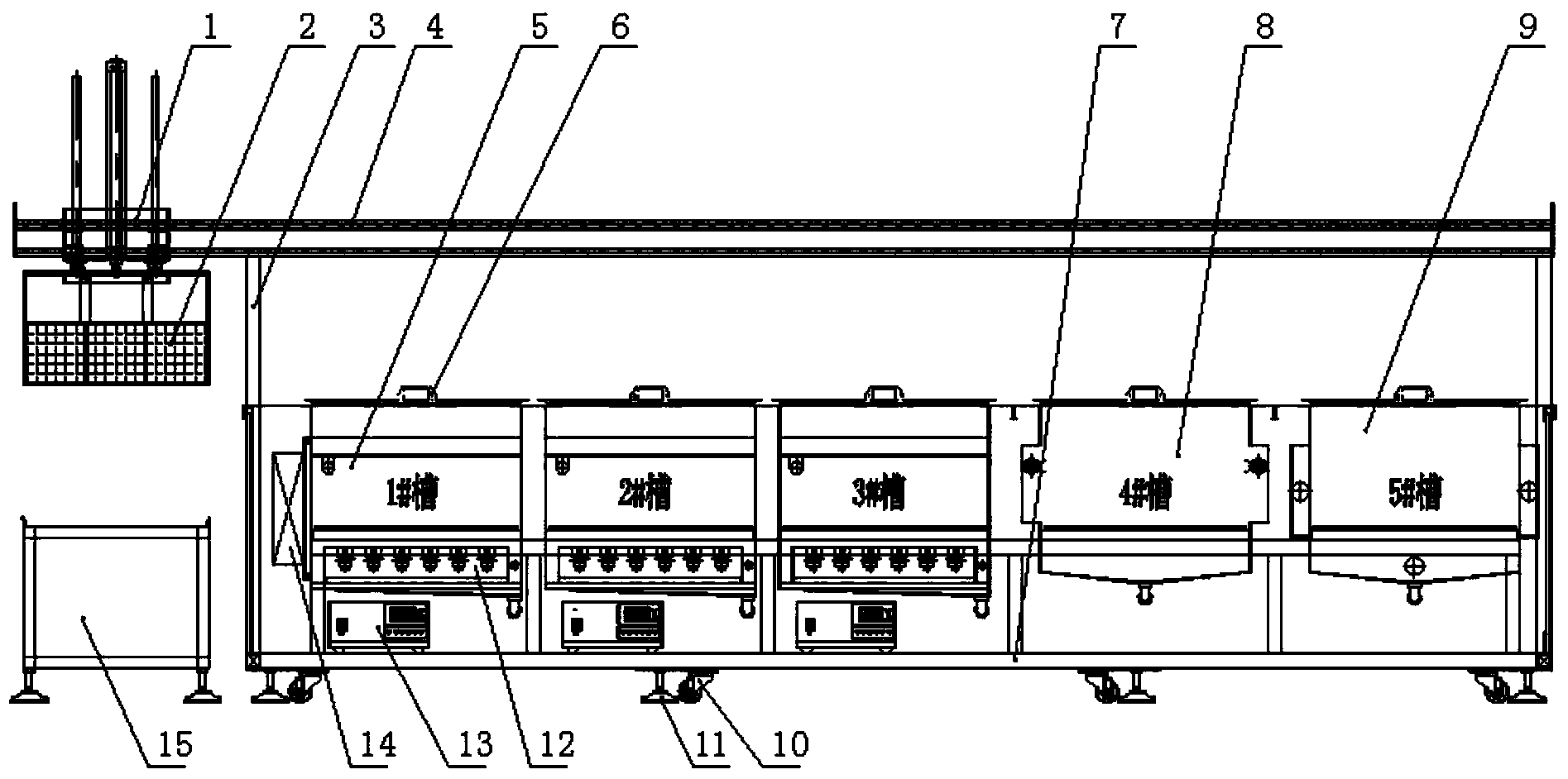

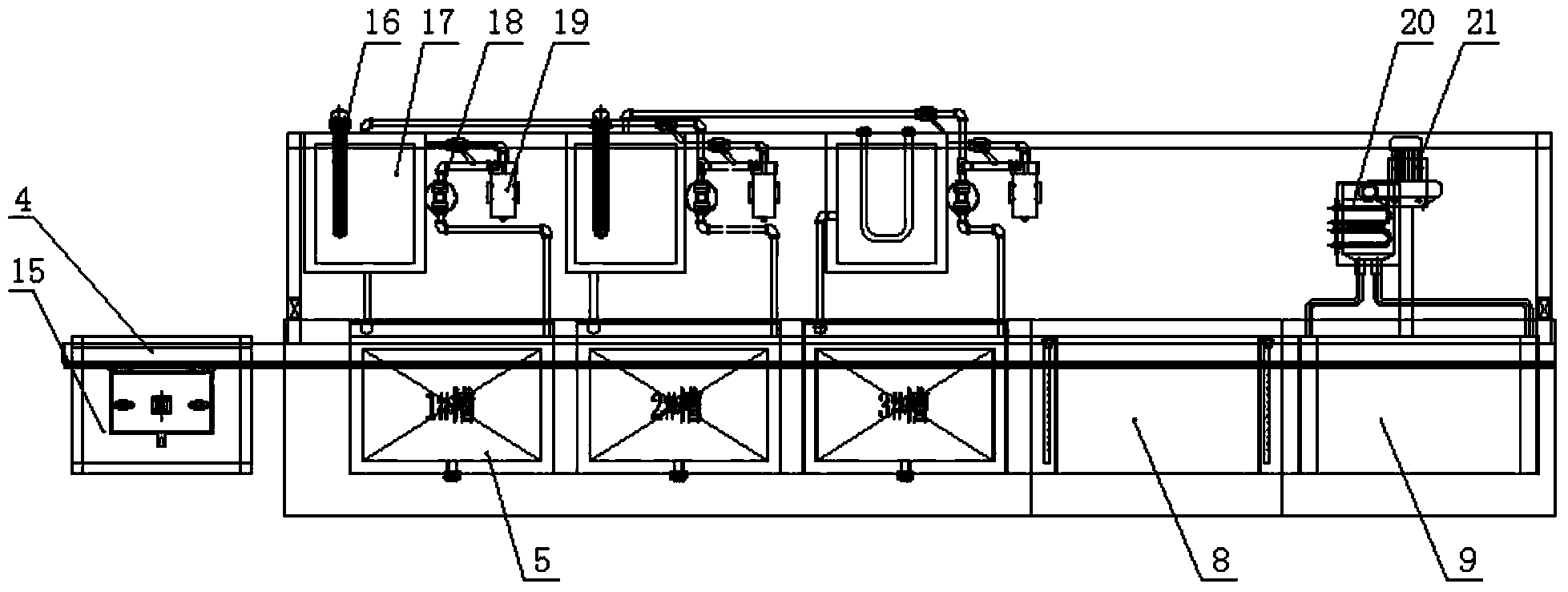

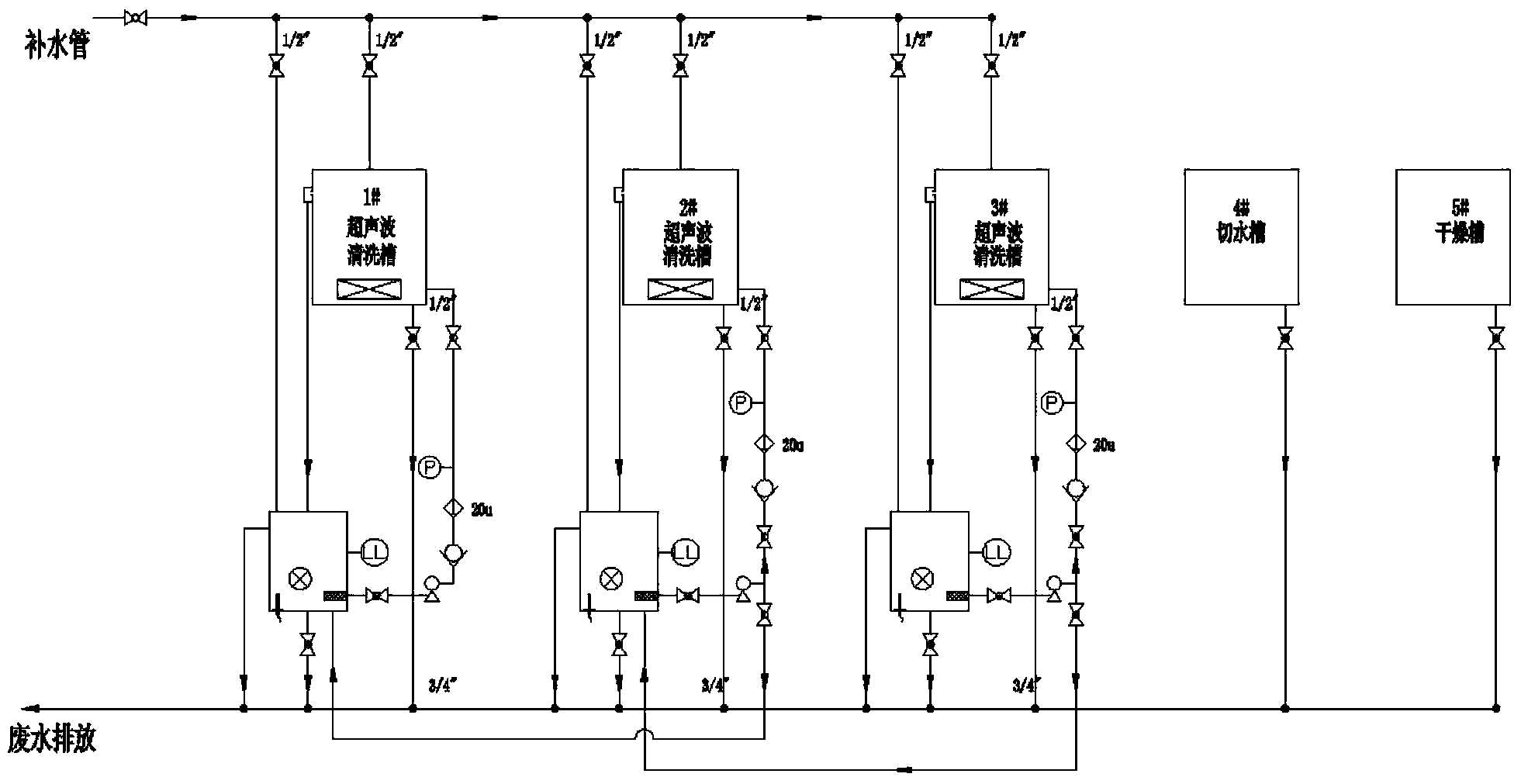

[0035] An ultrasonic cleaning device for plastic parts, such as figure 1 As shown, it includes a metal frame body 7, a cleaning basket 2, a manipulator 1 that drives the cleaning basket to move, a loading and unloading platform 15, and a control unit 14, and five groove bodies are installed horizontally in the metal frame body, and the five grooves are respectively three Two (1#, 2#, 3#) ultrasonic cleaning tanks 5, water cutting tanks 8 and drying tanks 9, the upper openings of the five tanks are respectively covered with upper covers 6, and the control unit is installed on the outermost ultrasonic cleaning tank. On the metal frame body on one side of the groove, the traversing guide rail 4 is laterally installed through the support frame 3 symmetrically arranged on both sides of the metal frame body above the five trough bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com