Method and equipment for cleaning pipeline

A technology for cleaning equipment and pipes, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. The effect of improving the cleaning effect and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

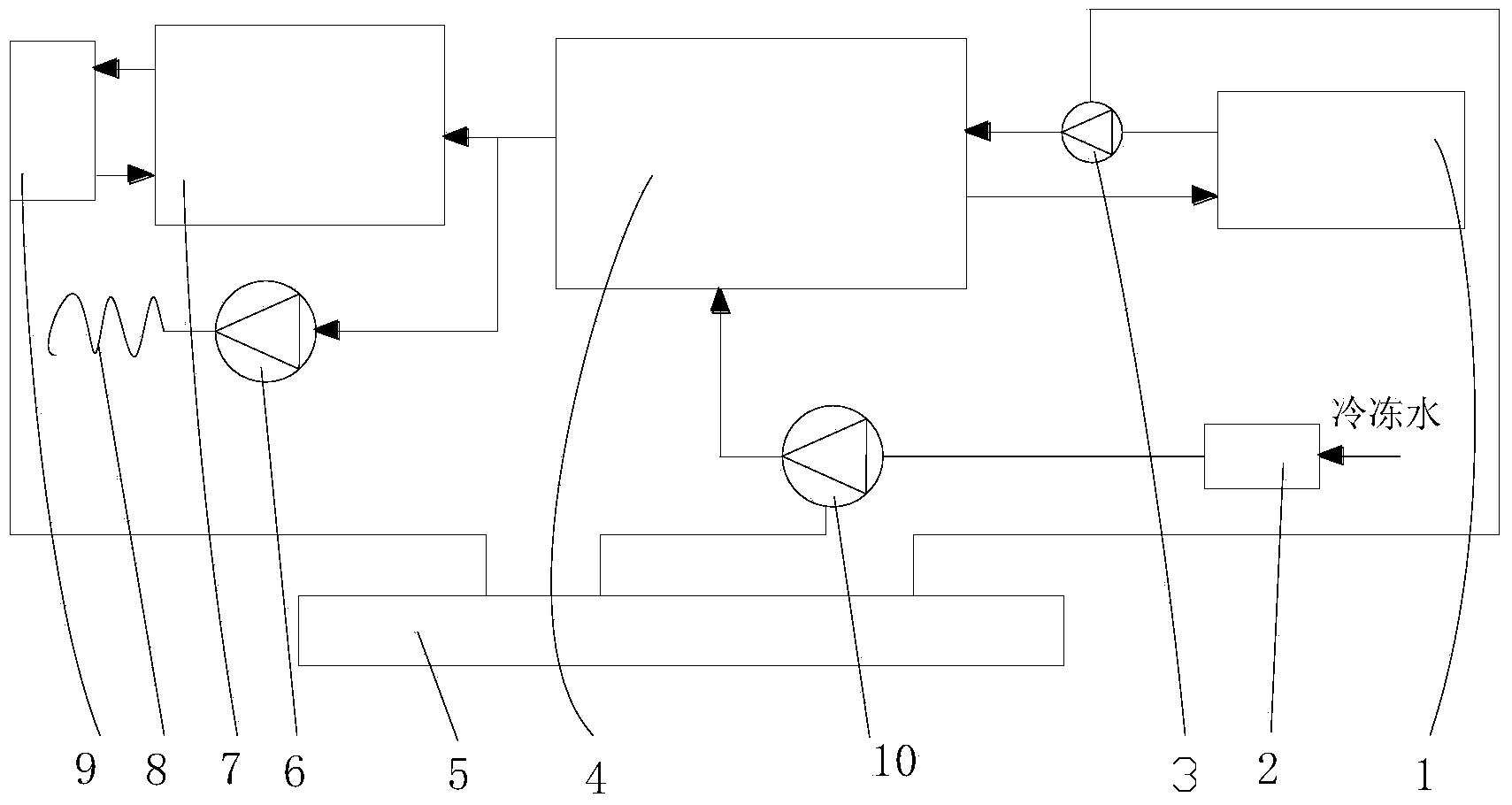

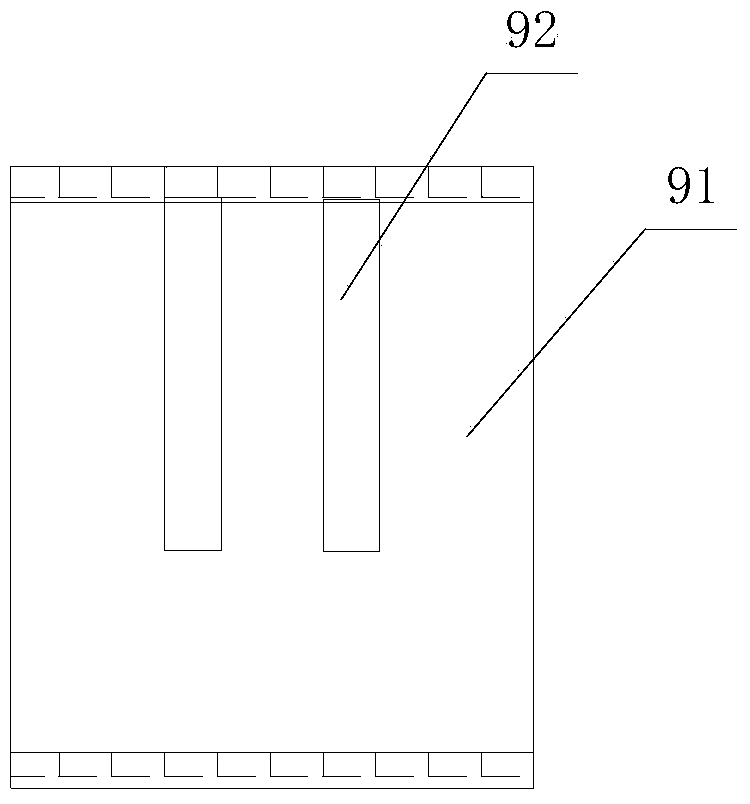

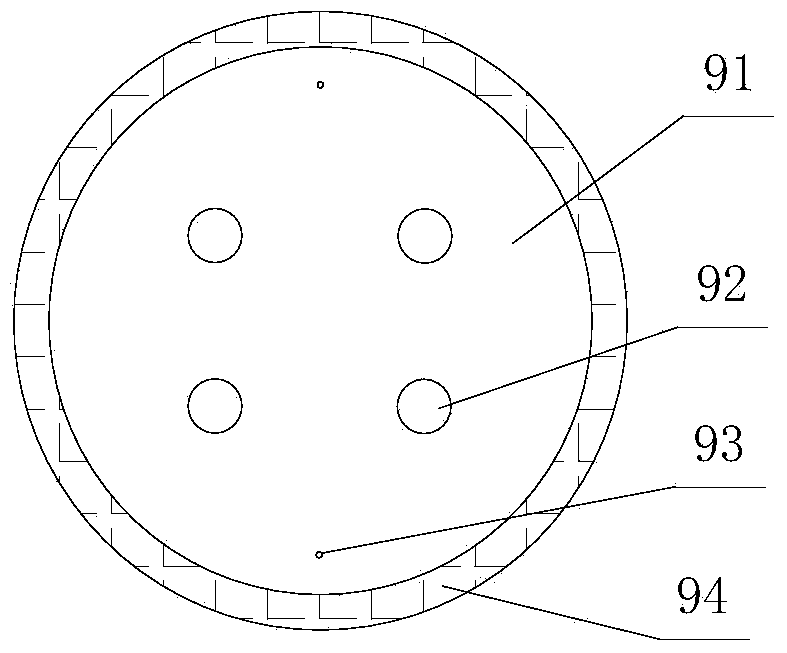

[0019] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

[0020] A method for cleaning pipelines uses ice slurry as the cleaning medium, and uses a positive displacement pump to drive the ice slurry to move in the pipeline during cleaning, and the ice slurry has an ice content of 10-50%.

[0021] The higher the ice content of the ice slurry, the greater the shear force.

[0022] The relationship between shear force and viscosity is:

[0023] τ = μ ∂ u ∂ y - - - ( 1 )

[0024] τ-shear force;

[0025] μ-viscosity;

[0026] -Shear rate;

[0027] It can be seen from formula (1) that the shear force is proportional to the viscosity at a certain shear rate, that is, the greater the viscosity, the greater the shear force. The laboratory measured the relationship between the ice content and the viscos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap