Work fixture for sand blasting and spraying of cylinder liners

A cylinder liner and sand blasting technology, which is applied in injection devices, manufacturing tools, used abrasive treatment devices, etc., can solve the problems of inability to meet the mass production of products, difficulty in regional protection, unstable quality, etc. The effect of labor intensity of workers, stable product quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

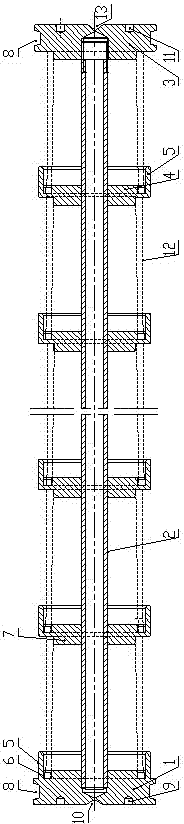

[0012] like figure 1 As shown, the cylinder liner sandblasting and spraying fixture of the present invention include a base 1, a connecting rod 2 and a pressing plate 3, and one end of the connecting rod 2 is fixedly connected with an end surface of the base 1 (one end of the connecting rod 2 is inserted In the base 1 and interferingly connected with the base 1), the other end of the connecting rod 2 is threadedly connected with one end surface of the pressing disc 3, and a set of limiting discs 4 are pierced on the connecting rod 2, and the base 1 and the limiting disc 4 A cylindrical protective tube 5 is provided on one side in the same direction of the same direction, and the base 1 and the limit plate 4 are provided with a circular positioning groove 6 located on the inner side of the limit ring, and the other side of the limit plate 4 and the Circular positioning discs 7 are respectively arranged on one side of the pressing disc 3 in the same direction, and the centerline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com