Movable type broken-belt catching device with buffer device

A technology of a broken belt catching device and a buffer device is applied in the conveyor control device, transportation and packaging, conveyor objects, etc. The effect of breaking the belt again, improving the safety operation factor, and preventing the injury accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

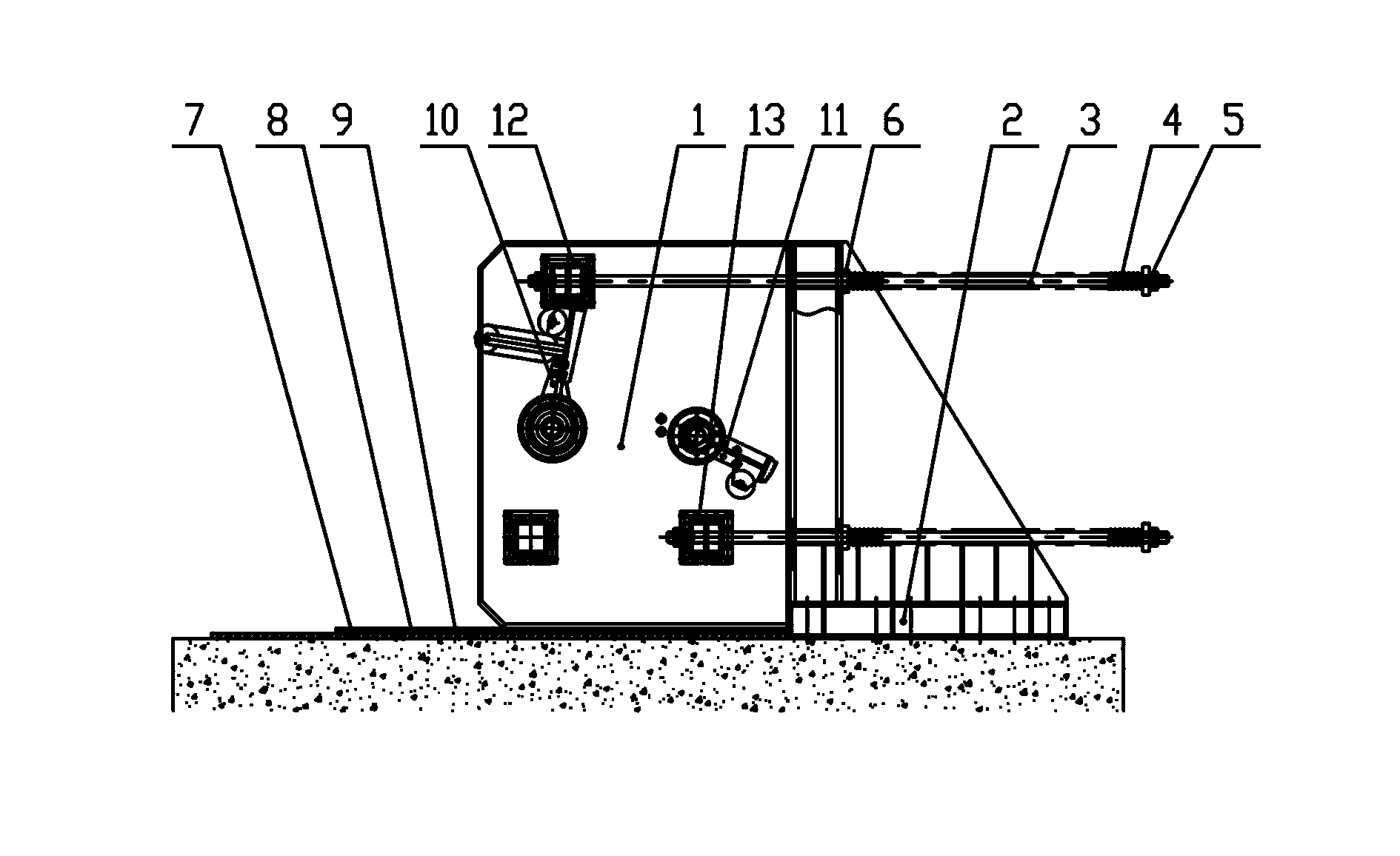

[0010] The movable broken belt arresting device with buffer device of the present invention, its preferred embodiment is as follows figure 1 As shown, the movable broken tape catcher with a buffer device includes a buffer device and a broken tape catcher 1 .

[0011] The buffer device includes a base 2, a shaft 3 and a spring 4. The base 2 is fixed on the ground through anchor bolts. The base 2 is provided with a shaft hole, the spring 4 is located on the shaft 3, and the side of the spring 4 is provided with a limit position. The nut 5 is provided with a blocking cap 6 on the other side, and a connecting shaft hole is arranged on the blocking cap 6. The blocking cap 6 is welded to the base 2, and the base 2 is connected to the broken belt arresting device 1 through the connecting shaft 3, and the connecting shaft 3 passes through The connecting shaft hole of the blocking cap 6 and the base 2 is connected with the broken belt arresting device 1 by bolts, a steel plate 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com